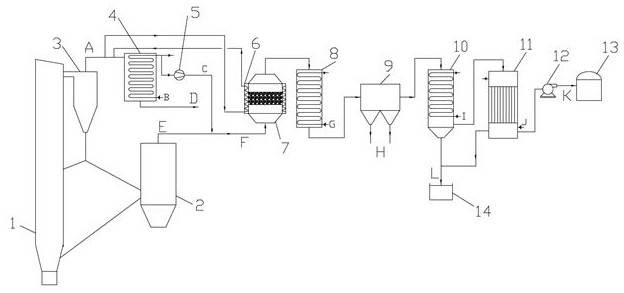

Device and method for preparing hydrogen-rich gas based on pyrolysis gas conversion of double fluidized beds

A dual-fluidized bed, pyrolysis gas technology, applied in the field of clean energy technology and coal chemical industry, can solve the problems of low energy utilization efficiency, less pyrolysis gas, less hydrogen content, etc., and achieve the effect of being conducive to stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The pyrolysis gas temperature at the outlet of the pyrolysis furnace is 650°C, the dust content is 12g / Nm3, the water vapor content is 26%, and the tar content is 115g / Nm 3 , The flue gas temperature at the outlet of the circulating fluidized bed boiler is 950°C. The pyrolysis gas is mixed with the high-temperature steam produced by the superheater on the flue gas side after being treated by the pressure reducing valve. After mixing, the steam content is 73%, and the water-to-carbon ratio is about 6. The mixed steam-rich pyrolysis gas is passed into the catalytic reactor, and the tar and water vapor in the pyrolysis gas undergo a reforming reaction under the action of the catalyst to generate hydrogen-rich gas. The outside of the reforming reactor is surrounded by a high-temperature heat exchanger. The hot-end medium of the high-temperature heat exchanger is high-temperature flue gas. The inlet temperature is 950°C, the outlet temperature is 850°C, and the catalytic rea...

Embodiment 2

[0062] The pyrolysis gas temperature at the outlet of the pyrolysis furnace is 700°C, the dust content is 15g / Nm3, the water vapor content is 13%, the tar content is 76g / Nm3, and the flue gas temperature at the outlet of the circulating fluidized bed boiler is 950°C. The pyrolysis gas is mixed with the high-temperature steam produced by the superheater on the flue gas side after being treated by the pressure reducing valve. After mixing, the steam content is 65%, and the water-to-carbon ratio is about 7. The mixed steam-rich pyrolysis gas is passed into the catalytic reactor, and the tar and water vapor in the pyrolysis gas undergo a reforming reaction under the action of the catalyst to generate hydrogen-rich gas. The outside of the reforming reactor is surrounded by a high-temperature heat exchanger. The hot-end medium of the high-temperature heat exchanger is high-temperature flue gas. The inlet temperature is 950°C, the outlet temperature is 850°C, and the catalytic reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com