Coal fire treatment and utilization system and method based on carbon dioxide process and modular design

A modular design, carbon dioxide technology, applied in lighting and heating equipment, fire prevention, mining equipment, etc., can solve the problems of large engineering volume, large water consumption, high cost, etc., achieve moderate temperature, suppress coal fire regeneration, and be easy to module effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

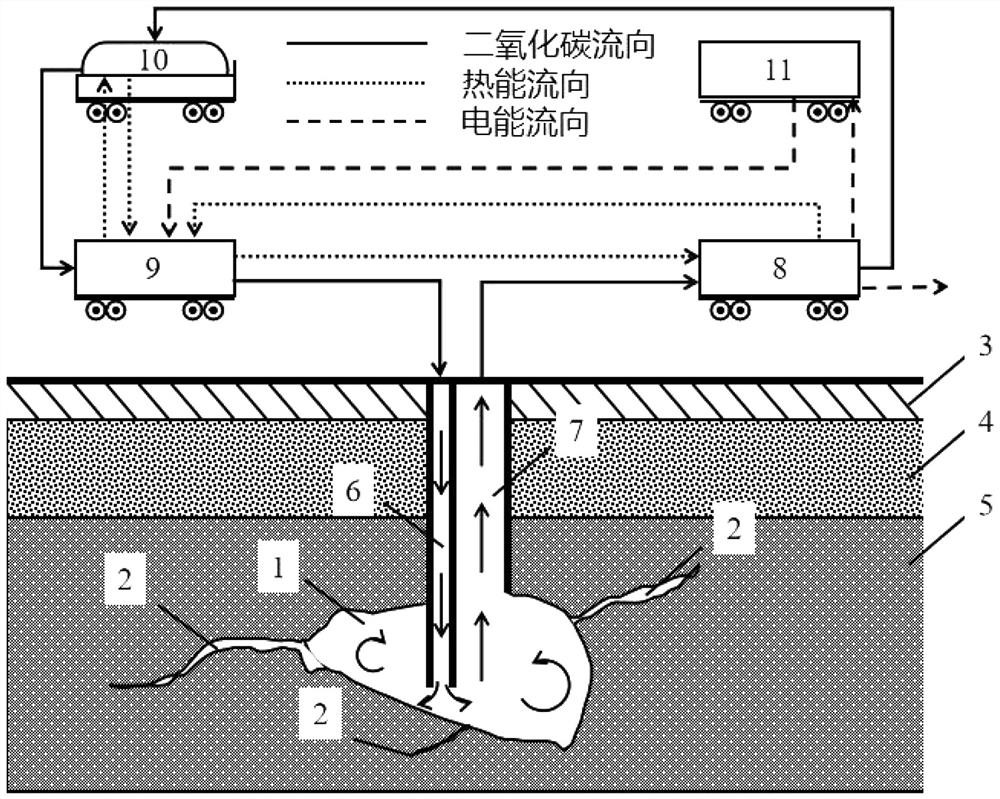

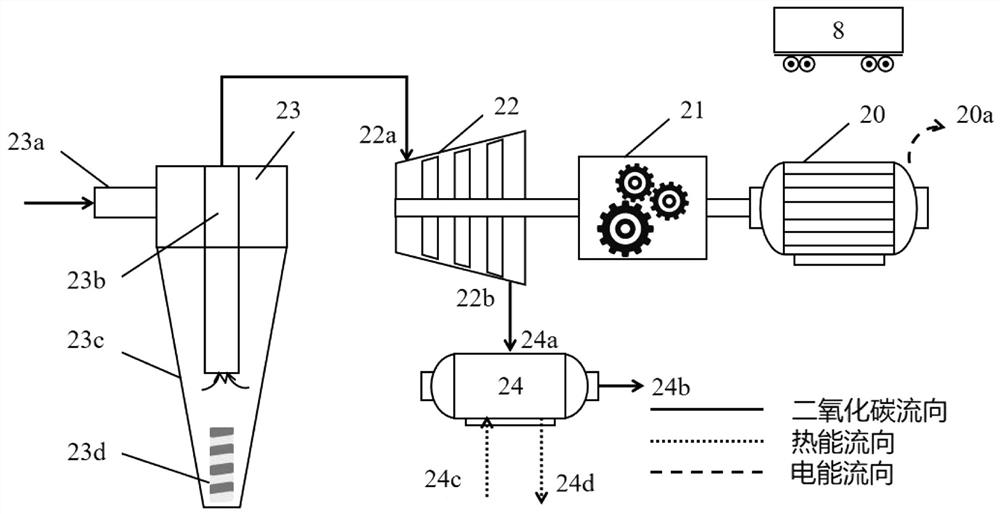

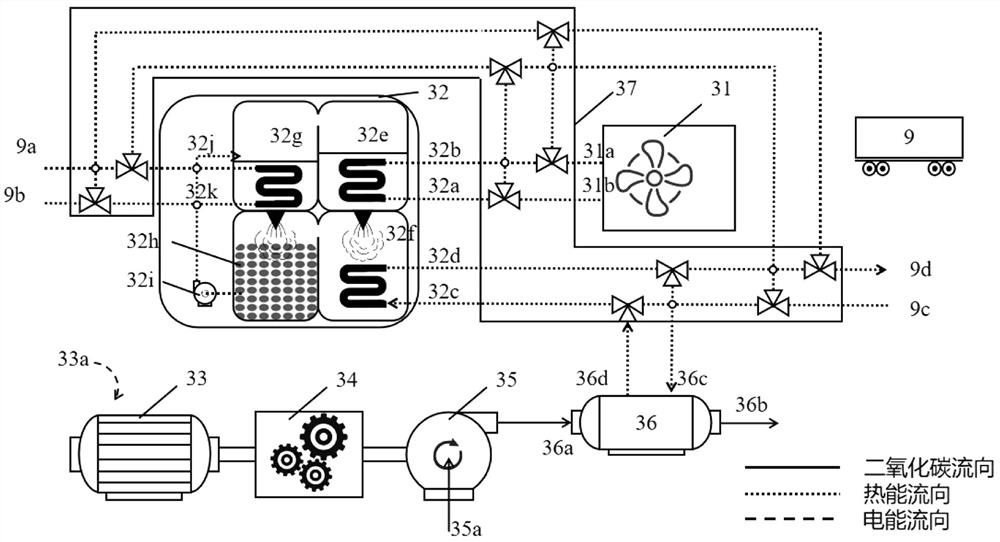

[0057] see Figure 1-4 , a coal fire treatment and utilization system based on carbon dioxide technology and modular design, which includes a heat source system for providing heat sources, and the heat source system is connected to a mobile power generation system for power generation; the heat source system includes an underground coal fire core area 1. The underground coal fire core area 1 is located inside the coal seam 5. A gaseous carbon dioxide collection well 7 is installed inside the coal seam 5 and communicated with the underground coal fire core area 1. The side of the gaseous carbon dioxide collection well 7 is provided with a carbon dioxide transmission line. Piping 6 ; the mobile power generation system includes four parts: a mobile expansion part 8 , a mobile booster part 9 , a mobile liquid carbon dioxide storage tank 10 and a mobile electric energy storage part 11 . By adopting the above-mentioned system, the side reaction of the carbon dioxide medium in the sp...

Embodiment 2

[0065] A coal fire treatment and utilization system based on carbon dioxide technology and modular design. In the treatment process, there are mainly three mass and energy flows: carbon dioxide flow, thermal energy flow and electric energy flow. The carbon dioxide fluid passes through the mobile expansion part 8, the mobile liquid carbon dioxide storage tank 10, the mobile booster part 9, the high temperature and high pressure liquid carbon dioxide transmission pipe 6, the coal fire core area 1, the gaseous carbon dioxide collection well 7, the mobile The expansion part 8 is sequentially connected to form a system to complete the thermodynamic cycle of carbon dioxide power generation.

[0066] Further, based on the operation method of the coal fire treatment and utilization system based on carbon dioxide technology and modular design, the system starts to be put into operation. In the heat source system, the underground space formed by the core area 1 of the underground coal fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com