Photo-anode film for reinforcing steel bar photoelectric cathode protection and preparation method and application thereof

A photocathode and photoanode technology, applied in electrolytic organic material coating, liquid chemical plating, coating and other directions, can solve the problems of low photo-generated electron-hole separation efficiency and poor cathodic protection effect, and achieve the expansion of light absorption and utilization Efficiency, increasing separation and transfer, effect of increasing separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Ru-Fe used for steel bar photocathode protection of the present invention 2 o 3 -The preparation method of PANI composite photoanode film, described preparation method comprises the following steps:

[0032] Step 1, using iron salt and urea as raw materials, prepare Fe on the conductive surface of a clean conductive substrate by hydrothermal method 2 o 3 ;

[0033] Step two, by electrochemical synthesis in Fe 2 o 3 Deposit polyaniline on the surface of Fe 2 o 3 -PANI composite photoanode film;

[0034] Step 3, by in situ chemical reduction method in Fe 2 o 3 - Surface preparation of PANI composite photoanode film to obtain Ru-Fe 2 o 3 -PANI composite photoanode film.

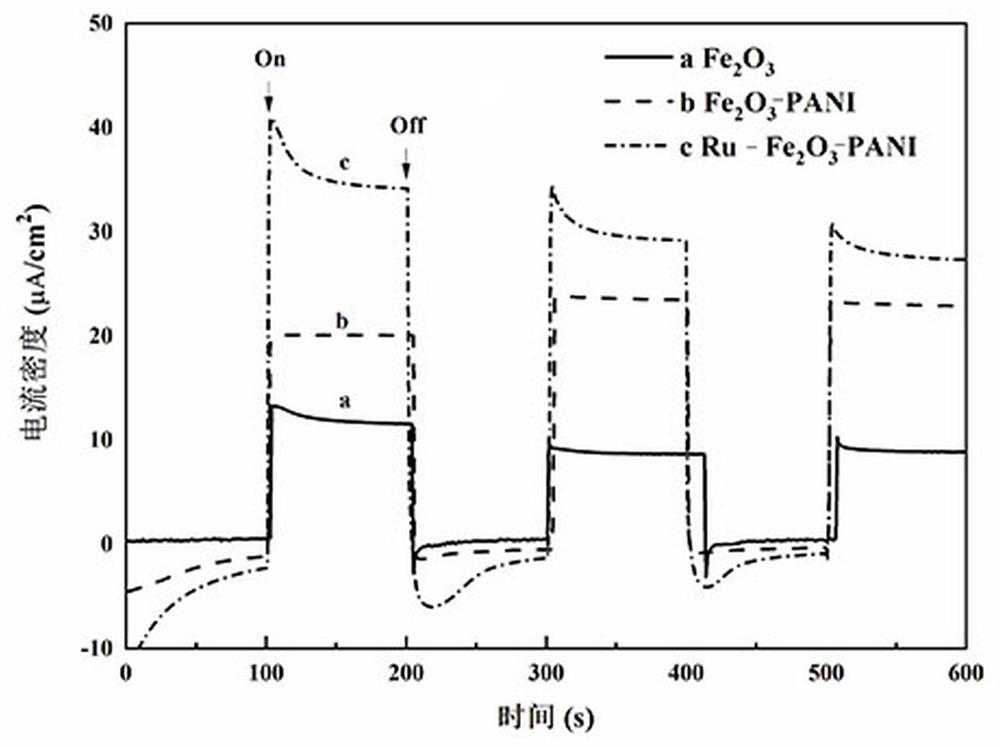

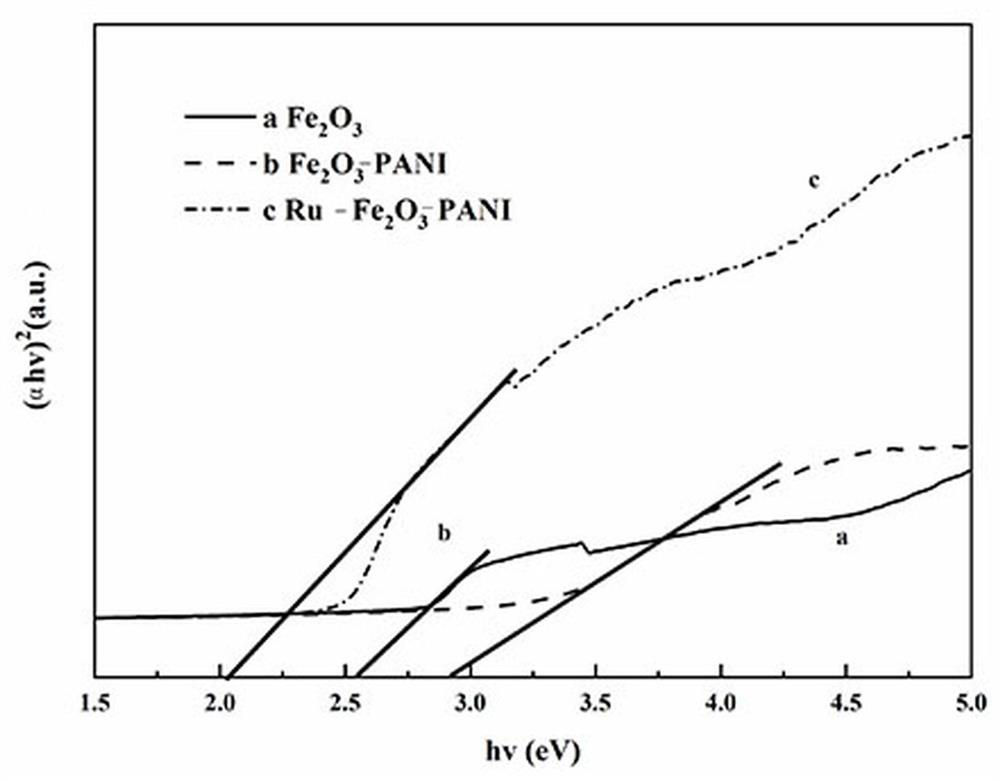

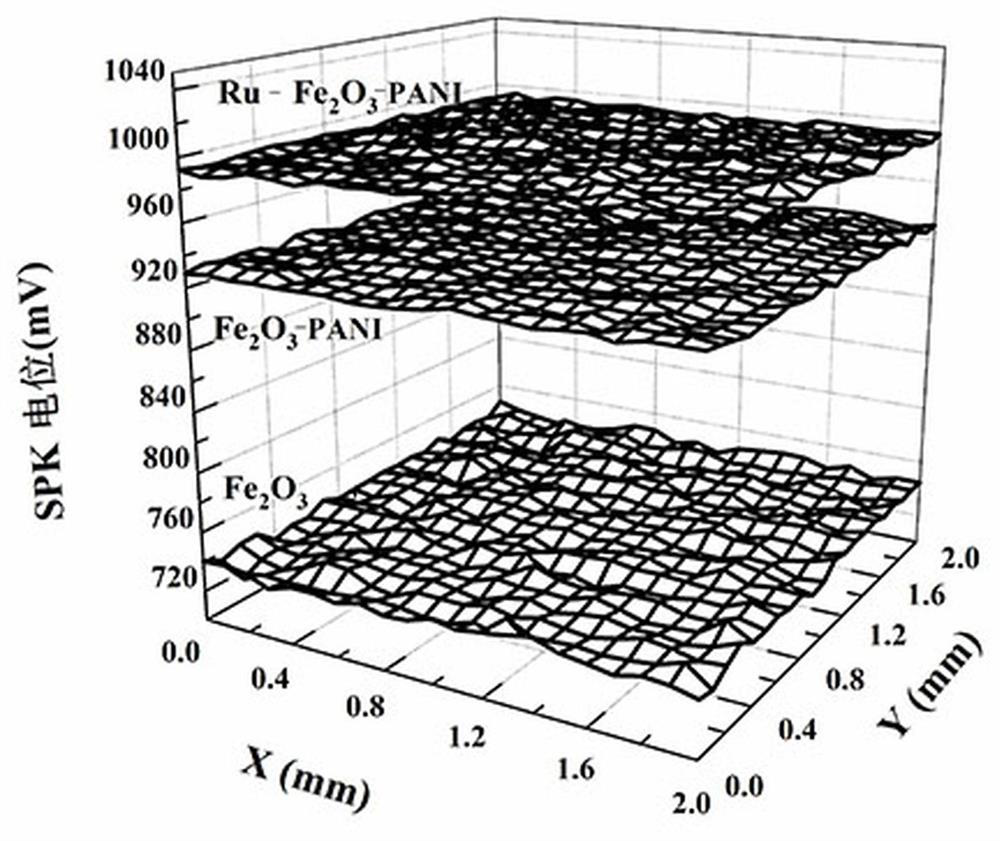

[0035] The present invention uses Ru-Fe 2 o 3 -PANI composite film is used as the cathodic protection photoanode of marine concrete structure, which can significantly expand the efficiency of light absorption and utilization, and improve the separation efficiency of photogenerated charges. ...

Embodiment 1

[0053] The Ru-Fe of this embodiment 2 o 3 -The preparation method of PANI composite photoanode film comprises the following steps:

[0054] First of all, before the hydrothermal reaction experiment, the FTO conductive glass needs to be thoroughly cleaned. The purpose is to improve the adhesion between the film and the FTO conductive glass. Put the FTO conductive glass into washing powder water and NaOH saturated ethanol in sequence. Solution, ethanol, and deionized water beakers, and ultrasonically cleaned in the above solution for 15 minutes in turn, and dried at 60°C for use. Then add 0.05 mmolL -1 of ferric chloride and 0.1 mmolL -1 Add the mixed solution of urea into the reaction kettle, adjust the pH of the mixed solution to 9 by adding sodium hydroxide, put the conductive side of the FTO conductive glass down into the mixed solution, control the hydrothermal temperature to 100°C, and the hydrothermal reaction time After 16 hours, after the reaction kettle was cooled,...

Embodiment 2

[0057] The Ru-Fe of this embodiment 2 o 3 -The preparation method of PANI composite photoanode film comprises the following steps:

[0058] First, before the hydrothermal reaction experiment, the FTO conductive glass needs to be thoroughly cleaned. The purpose is to improve the adhesion between the film and the FTO conductive glass. Put the FTO conductive glass into soapy water, NaOH ethanol solution, and ethanol in order. and a beaker in deionized water, and ultrasonically cleaned in the above solution for 15 minutes in turn, and dried at 60°C for use. Then add 0.5mmolL -1 of iron acetylacetonate and 0.5 mmolL -1 Add the mixed solution of urea into the reaction kettle, adjust the pH of the solution to 10 by adding potassium hydroxide, put the conductive side of the FTO conductive glass down into the mixed solution, control the hydrothermal temperature to 130°C, and the hydrothermal reaction time is 10 h, after the reaction kettle was cooled, the resulting solution was was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com