Method for applying inorganic mineral material wollastonite to PVC sheet instead of MBS resin

An inorganic mineral material, wollastonite technology, applied in the field of high-performance modification and processing of polymer materials, can solve the problems of inability to meet the requirements of mechanical properties, limited impact resistance, low impact resistance, etc., to promote the plasticity of materials. effect of chemical process, improved weather resistance, and enhanced flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

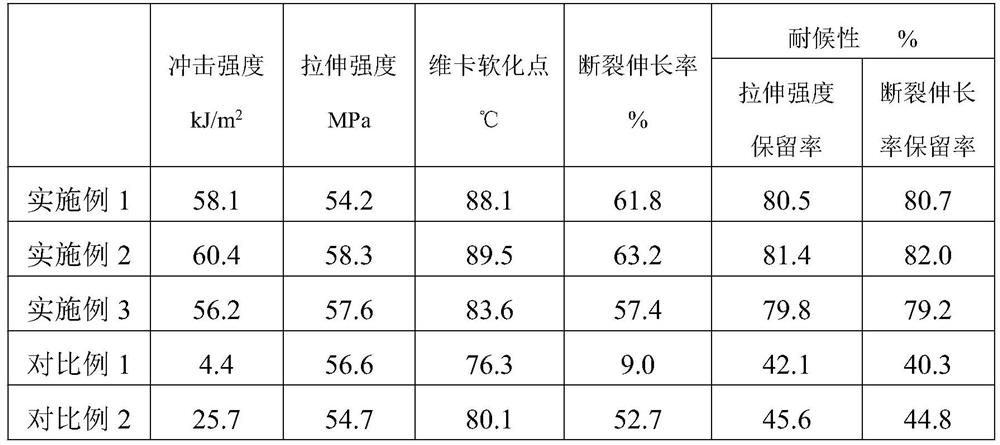

Examples

Embodiment 1

[0021] The method that inorganic mineral material wollastonite replaces MBS resin and is applied to PVC sheet comprises the following steps:

[0022] S1, take CaSiO 3 The mass content is 90%, the particle size is X 50 Wollastonite micro-nano powder with an aspect ratio of 5um and an aspect ratio of 12:1 is added with 2% of its mass silane coupling agent, the modification temperature is controlled at 80°C, and the modification time is 20 minutes.

[0023] S2. Cooperate the modified wollastonite powder obtained in step S1 with other raw materials, including: 100 parts of PVC resin, 0 part of MBS resin, 20 parts of modified wollastonite powder, 3 parts of organotin stabilizer, PE 0.2 parts of wax, 3 parts of chlorinated polyethylene, 5 parts of fatty acid amide synthetic lubricant, and 0.6 parts of high-pressure polyethylene.

[0024] S3. Add the raw materials and additives of step S2 into a high-speed mixer for dispersion and mixing. The high-speed mixer mixes at a stirring sp...

Embodiment 2

[0028] The method that inorganic mineral material wollastonite replaces MBS resin and is applied to PVC sheet comprises the following steps:

[0029] S1, take CaSiO 3 The mass content is 90%, the particle size is X 50 Wollastonite micro-nano powder with an aspect ratio of 5um and an aspect ratio of 12:1 is added with 2% of its mass silane coupling agent, the modification temperature is controlled at 80°C, and the modification time is 20 minutes.

[0030] S2. Cooperate the modified wollastonite powder obtained in step S1 with other raw materials, including: 100 parts of PVC resin, 6 parts of MBS resin, 14 parts of modified wollastonite powder, 3 parts of organotin stabilizer, PE 0.2 parts of wax, 3 parts of chlorinated polyethylene, 5 parts of fatty acid amide synthetic lubricant, and 0.6 parts of high-pressure polyethylene.

[0031] S3. Add the raw materials and additives of step S2 into a high-speed mixer for dispersion and mixing. The high-speed mixer mixes at a stirring s...

Embodiment 3

[0035] The method that inorganic mineral material wollastonite replaces MBS resin and is applied to PVC sheet comprises the following steps:

[0036] S1, take CaSiO 3 The mass content is 90%, the particle size is X 50 5um, wollastonite micro-nano powder with an aspect ratio of 12:1 is added with 2% of its mass of silane coupling agent, the modification temperature is controlled at 80°C, and the modification time is 20 minutes.

[0037] S2. Cooperate the modified wollastonite powder obtained in step S1 with other raw materials, including: 100 parts of PVC resin, 12 parts of MBS resin, 8 parts of modified wollastonite powder, 3 parts of organotin stabilizer, PE 0.2 parts of wax, 3 parts of chlorinated polyethylene, 5 parts of fatty acid amide synthetic lubricant, 0.6 parts of high pressure polyethylene;

[0038]S3. Add the raw materials and additives of step S2 into a high-speed mixer for dispersion and mixing. The high-speed mixer mixes at a stirring speed of 550rpm for 35 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com