High-flexibility, oil-resistant, low-smoke, halogen-free and flame-retardant cable material and preparation method thereof

A kind of flame retardant cable material, soft technology, applied in circuits, electrical components, plastic/resin/wax insulators and other directions, can solve the problems of complex processing, oil and temperature resistance hidden dangers, defects, etc., to improve mechanical properties, The effect of improving the heat resistance level and low smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

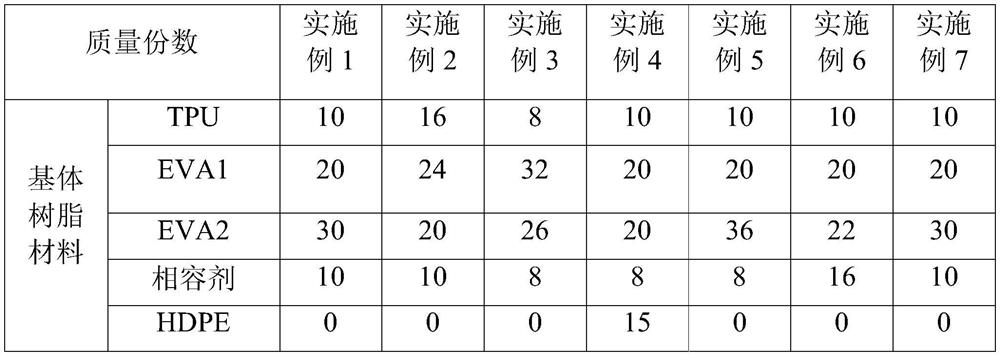

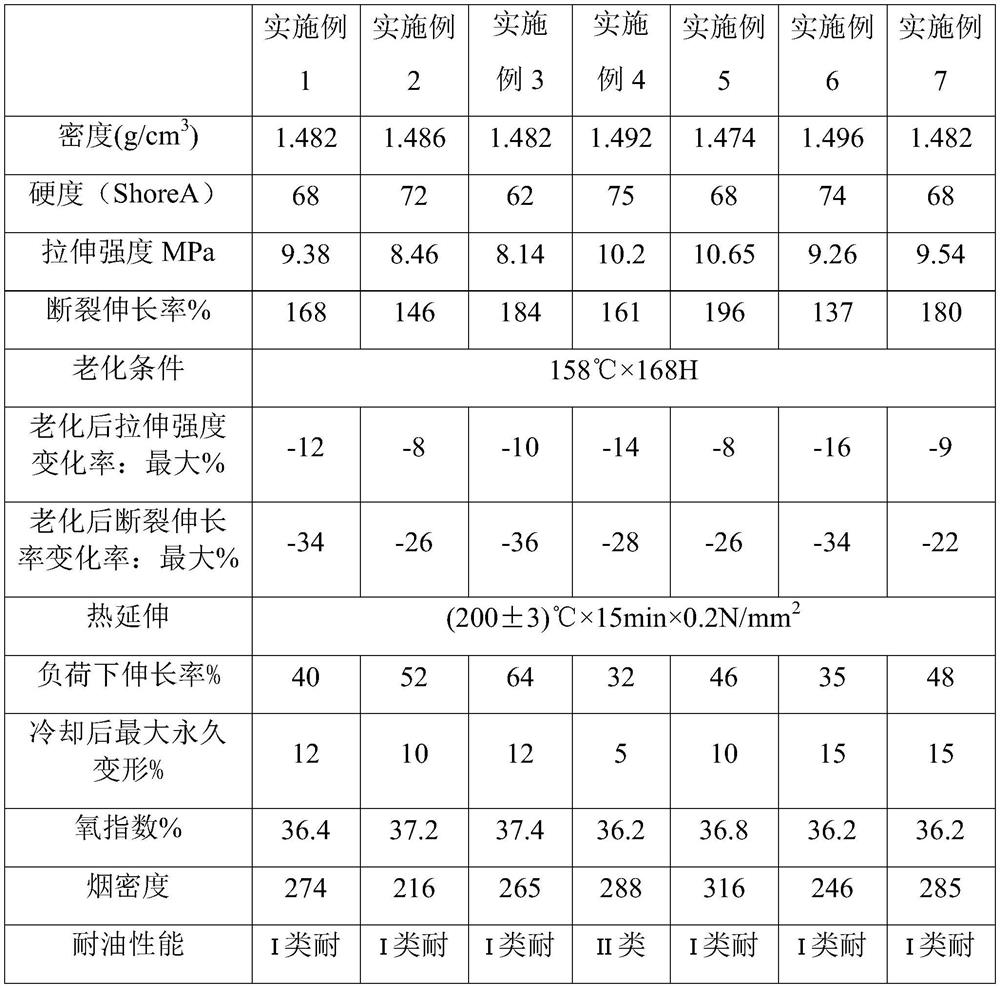

Embodiment 1

[0051] This example provides a highly flexible, oil-resistant low-smoke halogen-free flame-retardant cable material, the raw material formula of which is shown in Table 1, wherein:

[0052]Above-mentioned first class ethylene-vinyl acetate copolymer (EVA1) is the EV45LX of Mitsui-DuPont Company;

[0053] Above-mentioned second class ethylene-vinyl acetate copolymer (EVA2) is EVA260 of Mitsui-DuPont;

[0054] The fineness of the above-mentioned aluminum hydroxide is 10000 mesh, and the surface is modified by silane.

[0055] The preparation method of the above-mentioned highly flexible and oil-resistant low-smoke halogen-free flame-retardant cable material comprises the following steps:

[0056] Step A, weighing each component according to the above-mentioned raw material ratio;

[0057] Step B. Put the above-mentioned matrix resin material, antioxidant, inorganic flame retardant, auxiliary flame retardant, auxiliary crosslinking agent and processing aid in a high-speed mixer...

Embodiment 2

[0060] This example provides a highly flexible, oil-resistant low-smoke halogen-free flame-retardant cable material, the raw material formula of which is shown in Table 1, wherein:

[0061] Above-mentioned first class ethylene-vinyl acetate copolymer (EVA1) is the EV45LX of Mitsui-DuPont Company;

[0062] Above-mentioned second class ethylene-vinyl acetate copolymer (EVA2) is EVA260 of Mitsui-DuPont;

[0063] The fineness of the above-mentioned aluminum hydroxide is 10000 mesh, and the surface is modified by silane.

[0064] The preparation method of the above-mentioned highly flexible and oil-resistant low-smoke halogen-free flame-retardant cable material is as described in Example 1, and will not be repeated here.

Embodiment 3

[0066] This example provides a highly flexible, oil-resistant low-smoke halogen-free flame-retardant cable material, the raw material formula of which is shown in Table 1, wherein:

[0067] Above-mentioned first class ethylene-vinyl acetate copolymer (EVA1) is the EV45LX of Mitsui-DuPont Company;

[0068] Above-mentioned second class ethylene-vinyl acetate copolymer (EVA2) is EVA260 of Mitsui-DuPont;

[0069] The fineness of the above-mentioned aluminum hydroxide is 10000 mesh, and the surface is modified by silane.

[0070] The preparation method of the above-mentioned highly flexible and oil-resistant low-smoke halogen-free flame-retardant cable material is as described in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com