Manufacturing method of composite diaphragm paper for nickel-hydrogen low-self-discharge battery

A composite diaphragm and manufacturing method technology, applied in battery pack components, separators/films/diaphragms/spacer elements, circuits, etc., can solve the difference in battery state of charge, affect battery pack performance, and poor battery experience, etc. problems, to achieve the effect of small internal resistance of the battery, blocking or inhibiting the micro-short circuit of impurities, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 of the present application provides a method for making composite separator paper for Ni-MH low self-discharge batteries:

[0027] Step 1. Select an anti-dendrite diaphragm with a pore size between 0.01 and 100 microns, a uniform pore size, and a thickness of 5 to 80 microns;

[0028] Step 2. Use a surfactant treatment method to carry out hydrophilic treatment on the selected anti-dendrite diaphragm; the surfactant is cellulose acetate, tetrabutylammonium hydroxide, polyoxyethylene-type surfactant, polyol-type surfactant, NP - At least one of 10, PEP, IGEPAL Co-530 and VICTAWET-12; the principle is as follows:

[0029] Surfactants are composed of longer-chain hydrophobic groups (-R) and hydrophilic groups. When a hydrophobic diaphragm (such as PP or PE film) is soaked in an aqueous solution containing a surfactant, the hydrophobic part of the surfactant Attached to the hydrophobic surface, while the hydrophilic groups in the surfactant (such as -OH, -COOH,...

Embodiment 2

[0034] On the basis of Example 1, Example 2 of the present application provides another method for making composite separator paper for Ni-MH low self-discharge batteries:

[0035] Step 1. Select an anti-dendrite diaphragm with a pore size between 0.01 and 100 microns, a uniform pore size, and a thickness of 5 to 80 microns;

[0036]Step 2. Use a surfactant treatment method to carry out hydrophilic treatment on the selected anti-dendrite diaphragm; the surfactant is cellulose acetate, tetrabutylammonium hydroxide, polyoxyethylene-type surfactant, polyol-type surfactant, NP - At least one of 10, PEP, IGEPAL Co-530 and VICTAWET-12;

[0037] Step 2.1, add at least one of ethanol or acetone to the water, the mass fraction of the added chemical agent is 0.1% to 5%; continue to add the mass fraction of 0.5% fatty alcohol polyoxyethylene (10) ether (AEO-10) and VICTAWET-12 with a mass fraction of 0.01%, to obtain a hydrophilic solution.

[0038] Step 2.2. Soak the anti-dendrite dia...

Embodiment 3

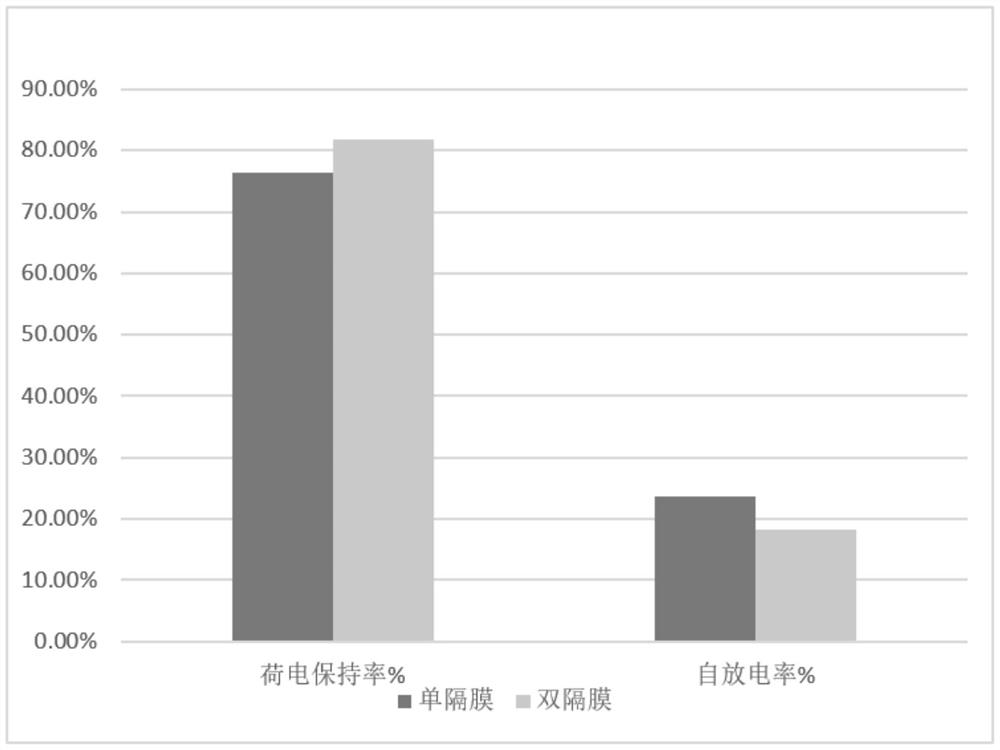

[0041] On the basis of Embodiment 1 to Embodiment 2, Embodiment 3 of the present application provides the application of composite separator paper for Ni-MH low self-discharge batteries in the manufacture of Ni-MH batteries:

[0042] Production of cylindrical Ni-MH 25Ah Ni-MH batteries: the positive electrode is 320g / m produced by Changsha Liyuan New Materials Co., Ltd. 2 Foamed nickel is used as the matrix material, and the spherical nickel is made of cobalt-coated spherical nickel in Kelong, Henan, C04 high-temperature spherical nickel from Jiangmen Changyou Industrial Co., Ltd. and additives (70% to 75%): (20% to 25%): (5% to 10%) ratio mixed and coated on the substrate by wet process, after drying, rolling and other processes to make the positive plate; the negative electrode alloy powder is made by wet process with Xiamen Tungsten MC01 alloy powder adding appropriate amount of additives; the diaphragm is made of Baolingsulfon The liquid-absorbing membrane and the lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com