Preparation method of protein peptide enhanced corn flour

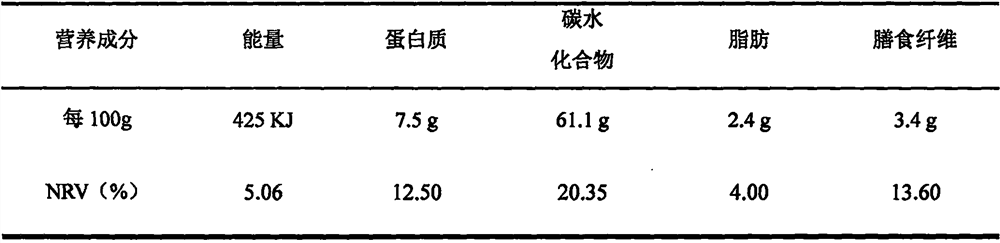

A production method and technology of corn flour, applied in protein-containing food ingredients, functions of food ingredients, food ultrasonic treatment, etc., can solve problems such as poor processing performance, indigestibility, and unbalanced amino acid composition, and achieve optimal immune regulation activity, The effect of simple manufacturing process and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

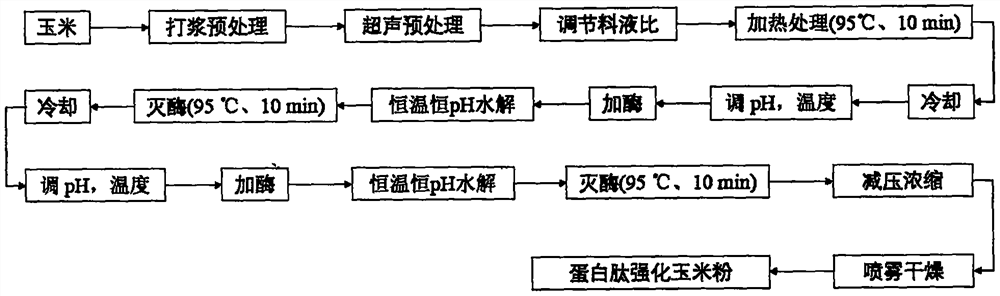

Method used

Image

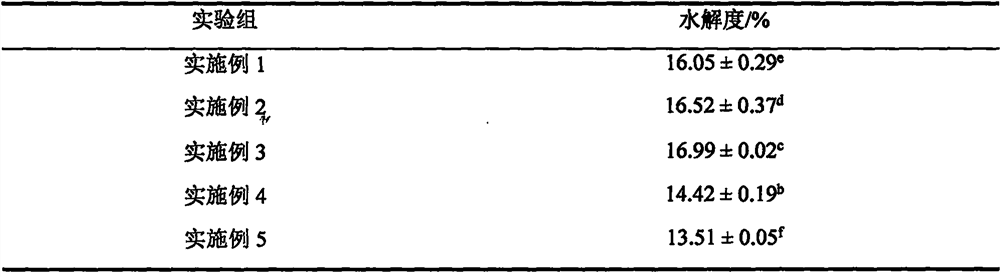

Examples

Embodiment 1

[0023] The preparation method of protein peptide enhanced corn flour, the specific implementation steps are as follows;

[0024] a, beating pretreatment

[0025] Select fresh, plump, clean and shiny corn kernels to clean, add distilled water twice its weight to soak for 10 minutes at 30°C, and use JMS-50 colloid mill for beating treatment under the condition of motor speed of 3500r / min and single cycle , to obtain pretreated corn slurry;

[0026] b. Ultrasonic pretreatment of corn slurry

[0027] Adjust the protein content of the pretreated corn slurry in step a to 3% by vacuum concentration, adjust the pH value to 7.0 with 1moL / L NaOH solution and HCl solution, and treat it for 5 minutes under the condition of ultrasonic power 500W, Obtain ultrasonic treatment corn slurry;

[0028] c. The first stage of enzymatic hydrolysis treatment

[0029] Heat the ultrasonically treated corn slurry to 90°C for 5 minutes, place it in a 35°C water bath to cool and keep the temperature c...

Embodiment 2

[0037] The preparation method of protein peptide enhanced corn flour, the specific implementation steps are as follows:

[0038] a, beating pretreatment

[0039] Select fresh, plump, clean and shiny corn kernels, wash them, add 6 times their weight in distilled water and soak for 60 minutes at 50°C, and use JMS-50 colloid mill for beating treatment under the condition of motor speed of 5000r / min and single cycle , to obtain pretreated corn slurry;

[0040] b. Ultrasonic pretreatment of corn slurry

[0041] Adjust the protein content of the pretreated corn slurry in step a to 10% by vacuum concentration, adjust the pH value to 7.0 with 1moL / L NaOH solution and HCl solution, and treat it for 25min under the condition of ultrasonic power 900W, Obtain ultrasonic treatment corn slurry;

[0042] c. The first stage of enzymatic hydrolysis treatment

[0043]Heat the ultrasonically treated corn slurry to 100°C for 10 minutes, place it in a 50°C water bath to cool and keep the tempe...

Embodiment 3

[0051] The preparation method of protein peptide enhanced corn flour, the specific implementation steps are as follows:

[0052] a, beating pretreatment

[0053] Select fresh, plump, clean and shiny corn kernels, wash them, add 6 times their weight in distilled water and soak for 60 minutes at 30°C, and use JMS-50 colloid mill for beating treatment under the condition of motor speed of 3500r / min and single cycle , to obtain pretreated corn slurry;

[0054] b. Ultrasonic pretreatment of corn slurry

[0055] Adjust the protein content of the pretreated corn slurry in step a to 5% by vacuum concentration, adjust the pH value to 7.0 with 1moL / L NaOH solution and HCl solution, and treat it for 15 minutes under the condition of ultrasonic power 900W, Obtain ultrasonic treatment corn slurry;

[0056] c. The first stage of enzymatic hydrolysis treatment

[0057] Heat the ultrasonically treated corn slurry to 95°C for 70 minutes, place it in a 40°C water bath to cool and keep the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com