Synthesis method of Y zeolite-silicon oxide composite material with core-shell structure

A synthesis method and composite material technology, which are applied in the field of core-shell structure Y zeolite-silica composite material and the synthesis field thereof, can solve the problems of difficult control of shell thickness, uneven coating of shell, easy falling off, etc. The effect of difficult to control shell thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

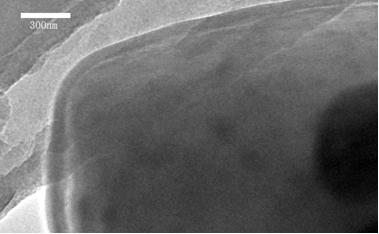

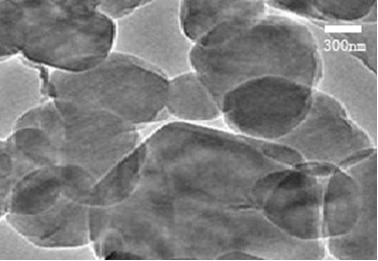

[0038]Take 1.32 g of Y zeolite, 2.04 g of octadecyltrichlorosilane, and 8.4 g of toluene, mix them in a water bath at 47 °C for 3 h, and then dry the sample at 120 °C for 10 h. Then mix with 0.0031 g tetraethyl orthosilicate and 1.25 g ethanol (measured as 0.95 g ethanol / 1 g zeolite by equal volume saturated impregnation method), and then place the sample on top of 120 g ethanol solution. Under treatment 2.2h. Then the sample was placed above a solution composed of 7 g of acetic acid, 130 g of ethanol, and 130 g of water, and the sample was not in contact with the solution, and treated at 45° C. for 15 hours. Then the obtained sample was washed 4 times with distilled water until neutral, dried at 120°C for 12 hours, and finally treated at 266°C for 4 hours to obtain the Y zeolite-silicon oxide composite material, and the obtained sample number was CL1. From figure 1 It can be seen that the obtained sample has a core-shell structure.

Embodiment 2

[0040] Take 1 g of Y zeolite, 3 g of octadecyltrichlorosilane, and 11 g of toluene, mix them in a water bath at 50 °C for 4 h, and then dry the sample at 120 °C for 10 h. Then mix with 0.01 g tetraethyl orthosilicate and 0.95 g ethanol (measured as 0.95 g ethanol / 1 g zeolite by equal volume saturated impregnation method), and then place the sample on top of 90 g ethanol solution. The sample is not in contact with the solution. Under treatment for 5h. Then the sample was placed above a solution composed of 4 g of acetic acid, 90 g of ethanol, and 90 g of water, and the sample was not in contact with the solution, and treated at 70° C. for 15 hours. Then the obtained sample was washed 4 times with distilled water until neutral, dried at 120°C for 12 hours, and finally treated at 280°C for 5 hours to obtain the Y zeolite-silicon oxide composite material, and the obtained sample number was CL2.

Embodiment 3

[0042] Take 1 g of Y zeolite, 0.6 g of octadecyltrichlorosilane, and 6 g of toluene, mix them in a water bath at 30 °C for 2 h, and then dry the sample at 120 °C for 10 h. Then mix with 0.001 g tetraethyl orthosilicate and 0.95 g ethanol (measured as 0.95 g ethanol / 1 g zeolite by equal volume saturated impregnation method), and then place the sample on top of 110 g ethanol solution. The sample is not in contact with the solution. Under treatment for 2h. Then the sample was placed above a solution consisting of 8 g of acetic acid, 110 g of ethanol, and 110 g of water, and the sample was not in contact with the solution, and treated at 20° C. for 60 h. Then the obtained sample was washed 4 times with distilled water until neutral, dried at 120°C for 12 hours, and finally treated at 200°C for 2 hours to obtain the Y zeolite-silicon oxide composite material, and the obtained sample number was CL3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com