A two-dimensional transition metal carbide/bismuth telluride or its derivative-based thermoelectric composite material and its preparation

A technology of transition metals and composite materials, applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of low electrical conductivity, uneven dispersion, high thermal conductivity, etc., to reduce thermal conductivity , wide application range, high thermoelectric performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-performance MXene / Sb2 Te 3 Preparation method of thermoelectric composite powder:

[0031] 2mmol SbCl 3 Disperse with 3mmol Te powder in 100ml water, then add 1.3g sodium hydroxide, 0.6g EDTA-2Na and 0.8g sodium borohydride, carry out hydrothermal reaction at 200°C, the reaction time is 12h, and obtain Sb 2 Te 3 Nano powder. Take 1g Sb 2 Te 3 The nanopowder was dispersed in 100 ml of ethanol solution, and 1 g of APTS was added as a surface modifier for modification. The modification temperature was 150° C. for 6 h, under nitrogen protection. After modification, filter with suction, wash with ethanol repeatedly 3 to 5 times, and dry under vacuum at 60°C. 10g modified Sb 2 Te 3 Disperse the powder in 200ml of water, adjust the pH value to 3, and add Ti with a mass ratio of 1wt% and a concentration of 3mg / ml dropwise while stirring. 3 C 2 T x Aqueous dispersion, Ti 3 C 2 T x coated with Sb 2 Te 3 Powder co-deposited, filtered, and vacuum dried at 60°...

Embodiment 2

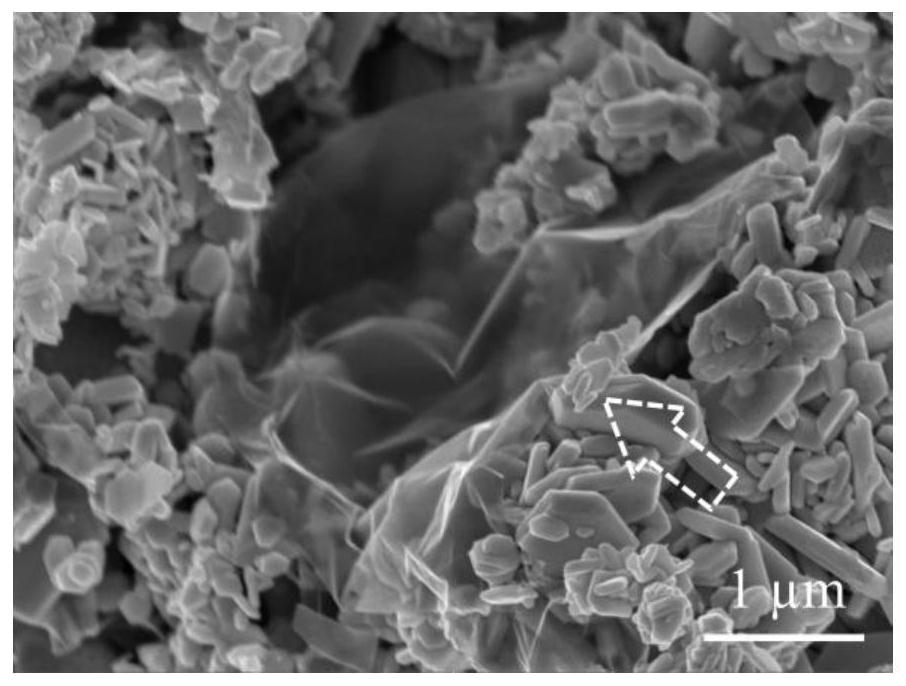

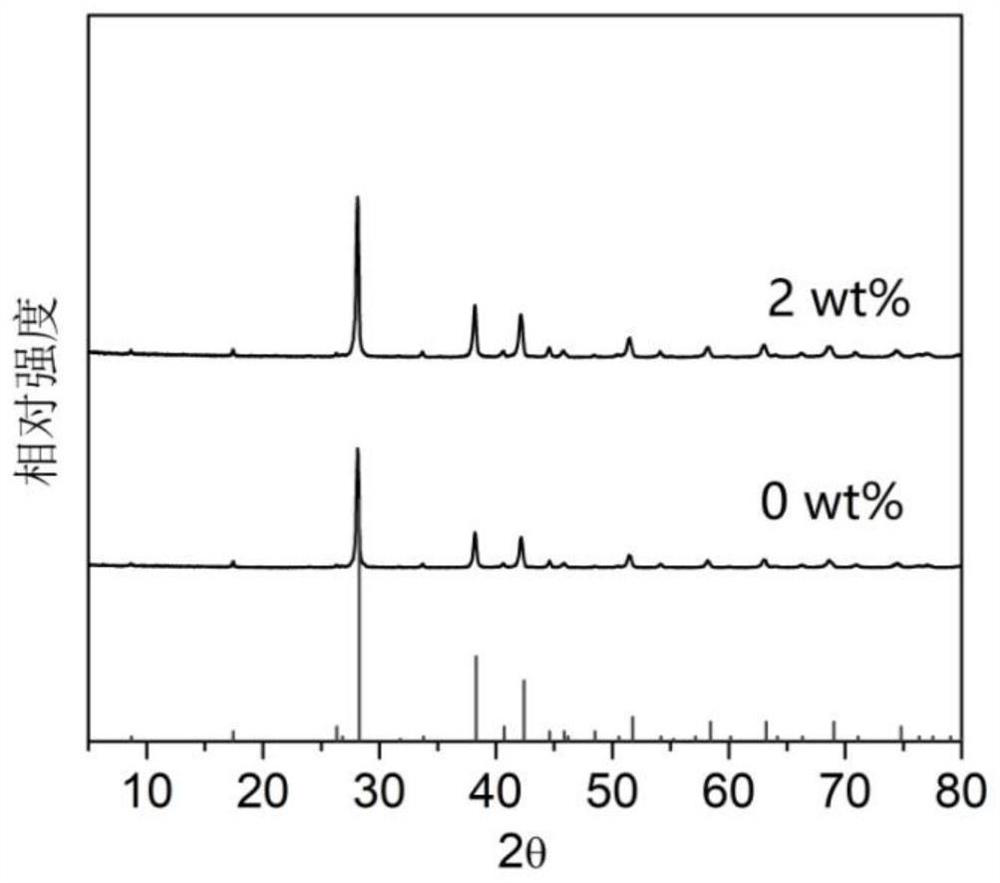

[0034] According to embodiment 1, in embodiment 1 " will 2mmol SbCl 3 and 3mmol Te powder dispersed in 100ml water "modify" to "0.5mmolBiCl 3 , 1.5 mmol SbCl 3 and 3mmol Te powder are dispersed in 100ml water ", all the other are identical with embodiment 1, obtain Bi 0.5 Sb 1.5 Te 3 Nano powder. Take 1g Bi 0.5 Sb 1.5 Te 3 The nanopowder was dispersed in 100 ml of toluene solution, Bi 0.5 Sb 1.5 Te 3 The modification process of the nanopowder is the same as in Example 1. 10g modified Bi 0.5 Sb 1.5 Te 3 Disperse the powder in 200ml of water, adjust the pH value to 3, and add Ti with a mass ratio of 2wt% and a concentration of 3mg / ml drop by drop while stirring 3 C 2 T x Aqueous dispersion, Ti 3 C 2 T x Wrapped with Bi 0.5 Sb 1.5 Te 3 The powders were co-deposited, filtered, and vacuum-dried at 60°C to obtain 2wt% Ti 3 C 2 T x / Bi 0.5 Sb 1.5 Te 3 Thermoelectric composite powder. The aqueous dispersion of MXene was not added as a control.

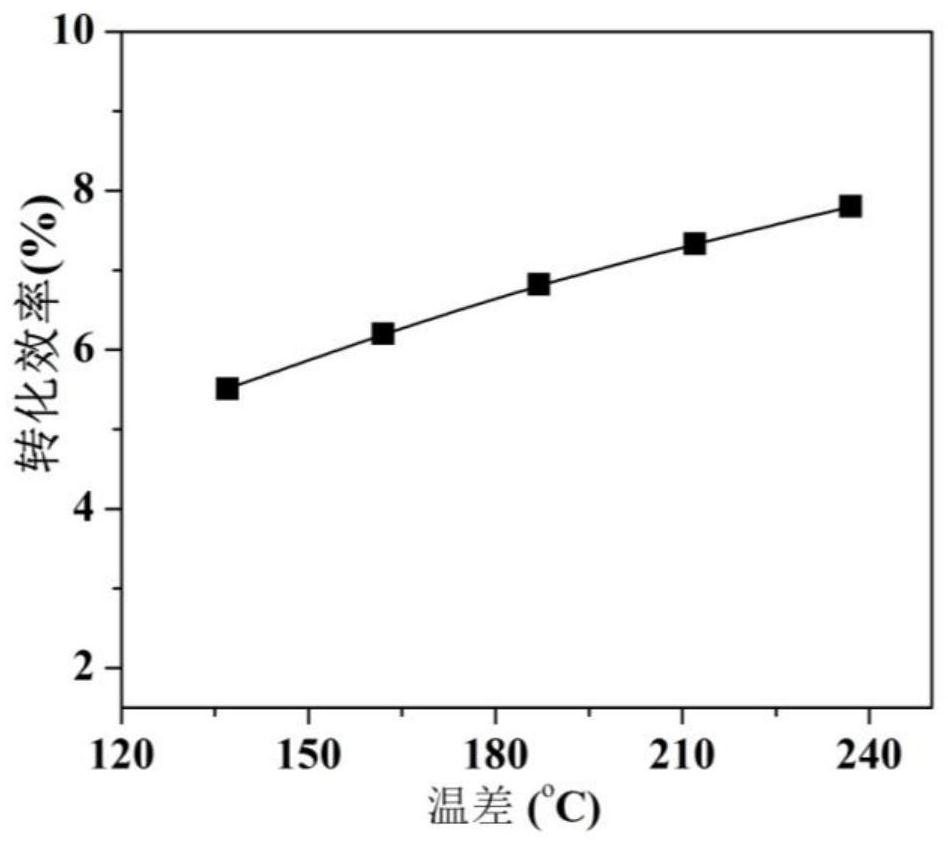

[0035] ...

Embodiment 3

[0037] High performance MXene / Bi 2 Te 3 Method for thermoelectric composite powder and bulk material prepared from the powder:

[0038] 2mmol BiCl 3 and 3 mmol TeO 2 Disperse the powder in 100ml of ethylene glycol, then add 1.5g of sodium hydroxide and 1g of PVP, and conduct a solvothermal reaction at 180°C for 16 hours to obtain Bi 2 Te 3 Nano powder. Take 1g Bi 2 Te 3 The nanopowder was dispersed in 100ml of toluene solution, and 1g APTS was added as a surface modifier for modification. The modification temperature was 130°C, and the modification time was 8h, under nitrogen protection. After modification, filter with suction, wash with ethanol repeatedly 3 to 5 times, and dry under vacuum at 60°C. 10g modified Bi 2 Te 3 Disperse the powder in 200ml of water, adjust the pH value to 2, and add Ti with a mass ratio of 1.5wt% and a concentration of 3mg / ml dropwise while stirring. 3 C 2 T x Aqueous dispersion, Ti 3 C 2 T x Wrapped with Bi 2 Te 3 Particles were c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com