Oxidation level heterogeneous p-n junction structure device and preparation method thereof

A heterogeneous and horizontal technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as complex process, high cost, and increased lattice defects, and achieve high carrier concentration and low production cost , The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

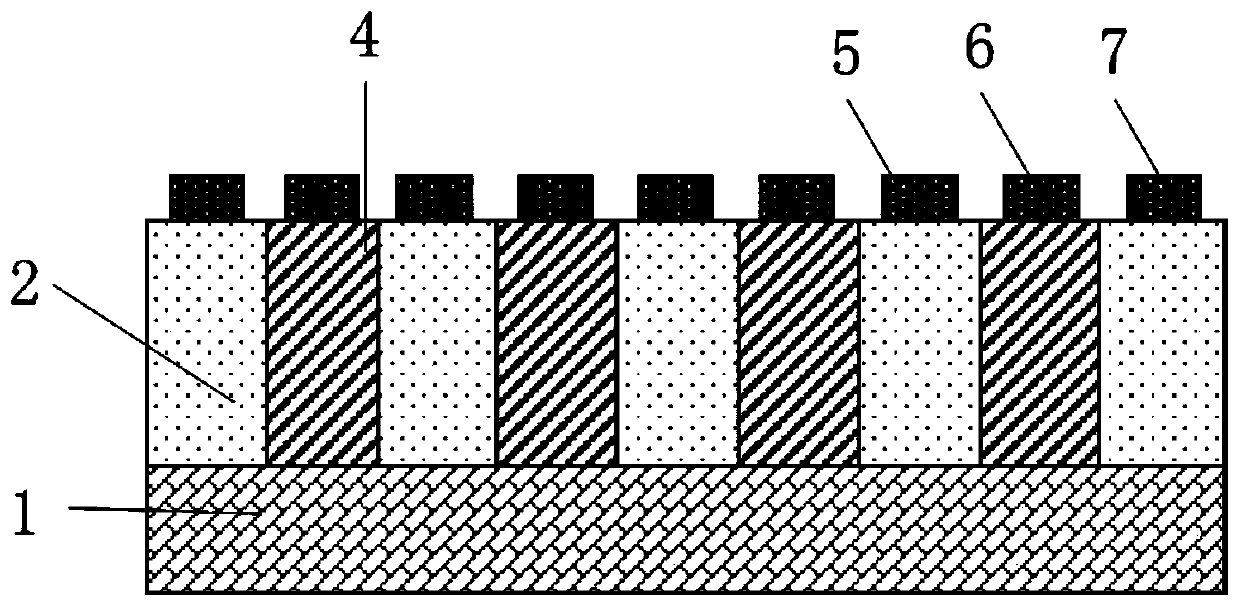

[0047] This embodiment provides a horizontal heterogeneous p-n junction structure, and the p-n junction structure device includes: a sapphire substrate, an n-type gallium nitride layer, a p-type gallium oxide layer embedded in the n-type gallium nitride layer, and a metal electrode . Such asfigure 1 Shown is a schematic diagram of an oxidation level heterogeneous p-n junction structure device. The bottom layer is a sapphire substrate 1, and the substrate 1 can also be a silicon substrate, a silicon carbide substrate, a diamond substrate, an aluminum nitride substrate, a gallium nitride homogeneous substrate, or boron nitride, graphene, Flexible substrates such as copper nickel. On the substrate 1 are alternately arranged n-type gallium nitride layers 2 and p-type gallium oxide layers 4 . The carrier concentration of the p-type gallium oxide layer 4 is 1×10 11 ~1×10 19 / cm 3 . The n-type gallium nitride layer can also be other n-type III-V compounds such as n-type indium ...

Embodiment 2

[0049] This embodiment provides the preparation method of the oxidation level heterogeneous p-n junction structure device of embodiment 1. It mainly includes the following steps:

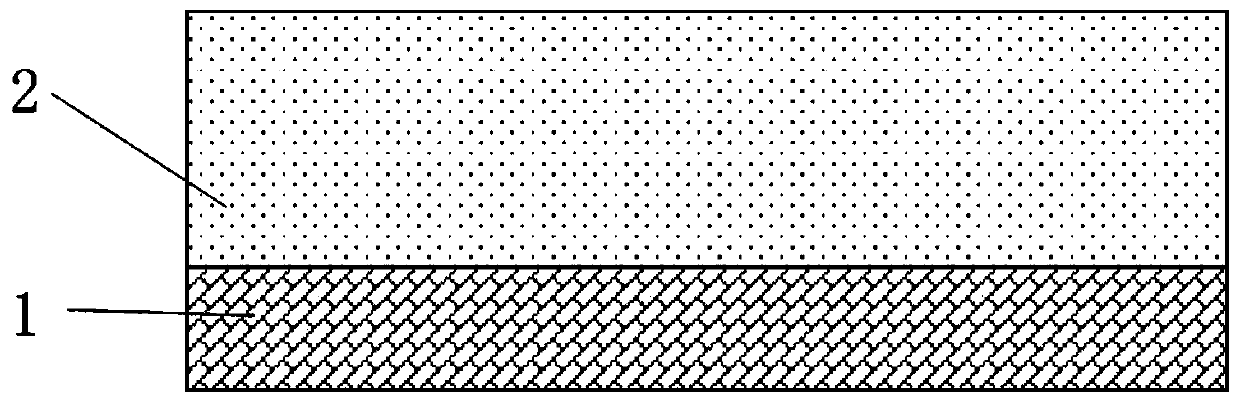

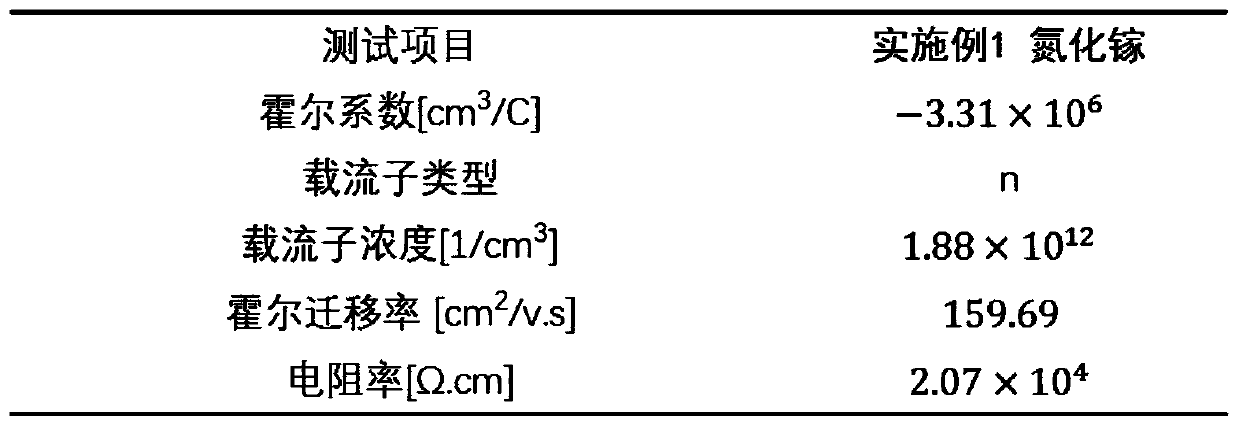

[0050] Step (1), growing a layer of n-type gallium nitride layer 2 on the sapphire substrate 1 with a thickness of 4 μm, figure 2 is a schematic diagram of the grown GaN layer, image 3 is the Hall test result of the grown gallium nitride layer, and the test result shows that the grown gallium nitride layer is an n-type gallium nitride layer.

[0051] Step (2), on the n-type gallium nitride layer, deposit a layer of aluminum oxide on the n-type gallium nitride layer as a mask 3 by atomic vapor deposition, Figure 4 It is a schematic diagram after depositing a mask layer on the n-type gallium nitride layer.

[0052] In step (3), by chemical vapor deposition, in the area not covered with the mask 3 on the n-type gallium nitride layer, the carrier concentration of thermal oxidation diffusion growth...

Embodiment 3

[0058] This embodiment provides a heterojunction field effect transistor device based on a horizontal heterogeneous p-n junction and a manufacturing method thereof. The heterojunction field effect transistor device comprises: a sapphire substrate 1 , an n-type gallium nitride layer 2 , a p-type gallium oxide layer 4 embedded in the n-type gallium nitride layer, and metal electrodes 5 , 6 , 7 . Such as Figure 12 Shown is a schematic diagram of a heterojunction field effect transistor device.

[0059] The preparation method of the heterojunction field effect transistor device specifically includes:

[0060] Step (1), growing a gallium nitride layer 2 on the sapphire substrate 1 with a thickness of 4 μm, figure 2 Schematic diagram of the grown GaN layer, image 3 It is the Hall test result of the grown gallium nitride layer, and the result shows that the grown gallium nitride layer is n-type.

[0061] Step (2), on the n-type gallium nitride layer 2, deposit a layer of alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com