A kind of nitride level heterogeneous p-n junction structure device and its preparation method

A horizontal and heterogeneous technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of high cost, low production efficiency, complex process, etc., to achieve low equipment requirements, low production cost, preparation Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

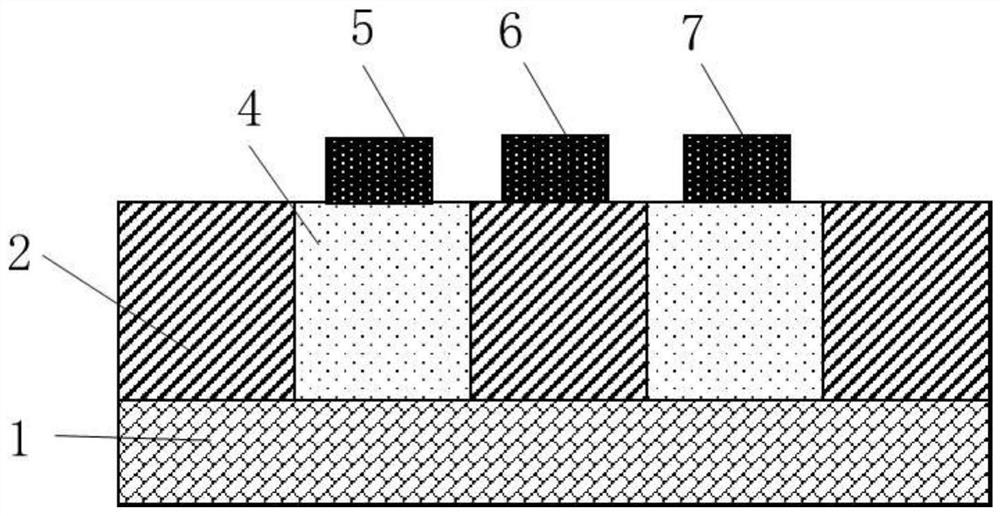

[0044] This embodiment provides a nitride level heterogeneous p-n junction structure device, the p-n junction structure device includes: a sapphire substrate, a p-type gallium oxide layer, an n-type gallium nitride layer embedded in the p-type gallium oxide layer, metal electrodes. Such as figure 1 Shown is a schematic diagram of a nitrided horizontal heterogeneous p-n junction structure device. The bottom layer is a sapphire substrate 1, and the substrate 1 can also be a silicon substrate, a silicon carbide substrate, a diamond substrate, an aluminum nitride substrate, a gallium nitride homogeneous substrate, or boron nitride, graphene, Flexible substrates such as copper nickel. On the substrate 1 are alternately arranged p-type gallium oxide layers 2 and n-type gallium nitride layers 4 . The carrier concentration of the n-type gallium nitride layer 4 is 1×10 11 ~1×10 19 / cm 3. The p-type gallium oxide layer can also be replaced by p-type indium oxide layer, p-type al...

Embodiment 2

[0046] This embodiment provides the preparation method of the nitride level heterogeneous p-n junction structure device in the first embodiment. It mainly includes the following steps:

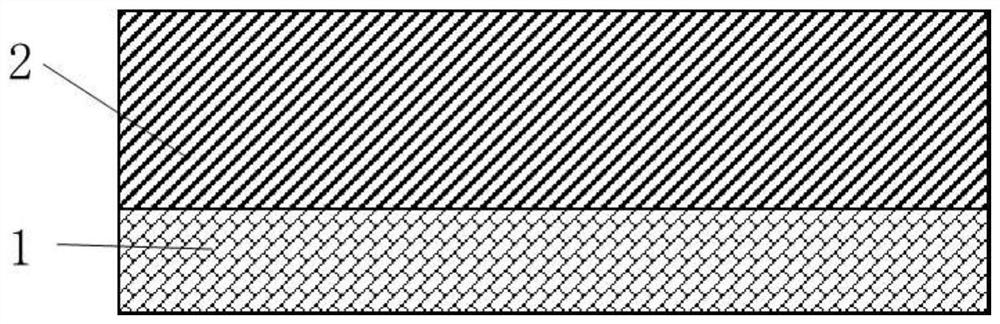

[0047] Step (1), growing a p-type gallium oxide layer 2 on the sapphire substrate 1 with a thickness of 3 μm, figure 2 It is a schematic diagram of the grown p-type gallium oxide layer.

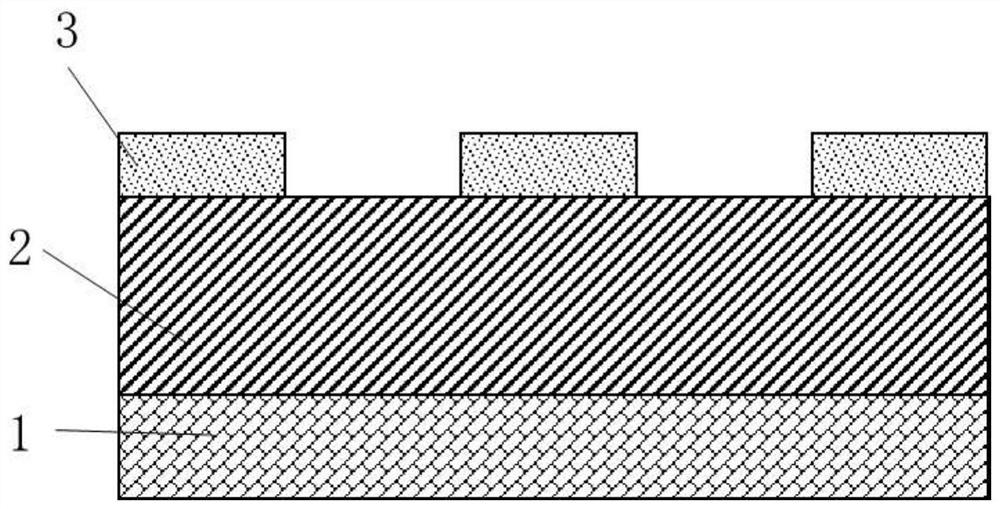

[0048] In step (2), on the p-type gallium oxide layer 2, a layer of silicon nitride mask 3 with a certain pattern is deposited on the p-type gallium oxide layer 2 by atomic vapor deposition, image 3 It is a schematic diagram after depositing a mask layer on the p-type gallium nitride layer.

[0049] In step (3), by chemical vapor deposition, on the region of the p-type gallium oxide layer 2 not covered with the mask 3, the carrier concentration is 1×10 by thermal nitriding diffusion from the upper surface to the lower surface 11 ~1×10 20 / cm 3 n-type gallium nitride layer 4, so that the n-type gallium ...

Embodiment 3

[0054] This embodiment provides a heterojunction field effect transistor device based on a horizontal heterogeneous p-n junction structure and its preparation method. The heterojunction field effect transistor device includes: a sapphire substrate 1, a p-type gallium oxide layer 2, an embedded The n-type gallium nitride layer 4 inside the p-type gallium oxide layer 2 and the metal electrodes 5, 6, 7. Such as Figure 6 Shown is a schematic diagram of a heterogeneous p-n junction field effect transistor device.

[0055] The preparation method of the heterojunction field effect transistor device includes:

[0056] Step (1), growing a p-type gallium oxide layer 2 on the sapphire substrate 1 with a thickness of 3 μm, figure 2 Schematic diagram of the grown gallium oxide layer.

[0057] Step (2), on the p-type gallium oxide layer 2, deposit a layer of hafnium dioxide on the p-type gallium oxide layer as a mask 3 by means of atomic vapor deposition, Figure 7 It is a schematic d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com