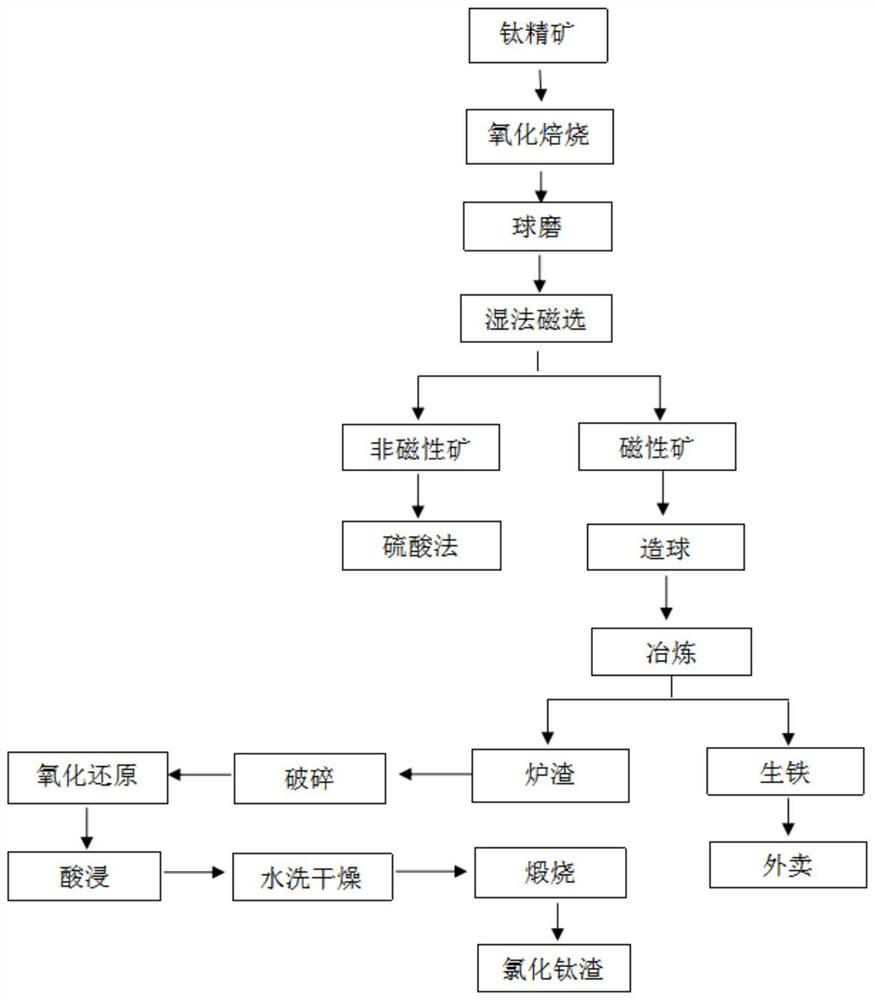

Method for preparing titanium chloride slag from titanium concentrate

A titanium concentrate and titanium chloride technology, applied in the direction of titanium halide, etc., can solve the problems of small production scale, low grade, high cost, etc., and achieve the effect of easy operation, simple equipment, and improved grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A Panzhihua titanium concentrate (TiO 246.83 wt%, TFe27.68 wt%, CaO 1.46 wt%, MgO3.5 wt%, SiO 2 3.39wt%) into a fluidized bed, oxidized and roasted at 680°C for 2 hours in an air atmosphere, ball milled for 10 minutes, and wet magnetic separation was carried out at a strength of 3000GS, and the obtained magnetic ore was added to starch for granulation (pelleting) ; then directly add the granulated sample and reducing agent coke into the smelting furnace, and after smelting at 1550°C for 8 hours, separate the slag and iron to obtain the slag; after crushing the slag, put it into the rotary kiln and oxidize it at 900°C for 1 hour in the air atmosphere , and then use coal as a reducing agent to reduce in a rotary kiln at 800°C for 1 hour to obtain modified slag; mix the modified slag with 21% hydrochloric acid at a liquid-solid ratio of 1:5, react at 120°C for 6 hours, and wash with water Dry, then calcined at 1000°C for 1h to obtain titanium chloride slag, the main comp...

Embodiment 2

[0042] A Panzhihua titanium concentrate (TiO 2 46.83wt%, TFe 27.68wt%, CaO 1.46wt%, MgO3.5wt%, SiO 2 3.39wt%) into a fluidized bed, oxidized at 750°C for 1 hour in an air atmosphere, ball milled for 15 minutes, and wet magnetic separation was carried out at a strength of 4000 GS, and the obtained magnetic ore was added to starch for granulation; The sample and the reducing agent coke are directly added to the smelting furnace, and after smelting at 1550°C for 6 hours, the slag and iron are separated to obtain slag; the slag is put into the rotary kiln and oxidized at 950°C for 1 hour in an air atmosphere, and then coal is used as the reducing agent. Reduction at 850°C for 1 hour in a rotary kiln to obtain modified slag; mix modified slag with 21% hydrochloric acid at a liquid-solid ratio of 1:8, react at 180°C for 2 hours, wash and dry, and then calcined at 1000°C 1h to get titanium chloride slag, its main composition TiO 2 91.93wt%, TFe0.32wt%, CaO0.18wt%, MgO0.94wt%, SiO...

Embodiment 3

[0044] A Panzhihua titanium concentrate (TiO 2 46.83 wt%, TFe27.68 wt%, CaO 1.46 wt%, MgO3.5 wt%, SiO 2 3.39wt%) into a fluidized bed, oxidized at 730°C for 1.5h under an air atmosphere, ball milled for 10min, and then wet magnetic separation was carried out at a strength of 3000GS, and the obtained magnetic ore was added to starch for granulation; Pellet samples and reducing agent coke are directly added to the smelting furnace, and after smelting at 1550°C for 9 hours, the slag and iron are separated to obtain slag; the slag is put into the rotary kiln and oxidized at 800°C for 1 hour in an air atmosphere, and then coal is used as the reducing agent , reduced at 750°C for 1 hour in a rotary kiln to obtain modified slag; mixed modified slag with 21% hydrochloric acid at a liquid-solid ratio of 1:6, reacted at 150°C for 2 hours, washed and dried, and then dried at 1000°C Calcined for 2 hours to obtain titanium chloride slag, the main composition of which is TiO 2 90.75wt%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com