Continuous production method suitable for ibuprofen Friedel-Crafts reaction

A technology of Friedel-Crafts reaction and production method, applied in the field of continuous production of Friedel-Crafts reaction of ibuprofen, can solve the problems of large fluctuation of product quality, many manual operation steps, low production efficiency and the like, and achieves shortening reaction residence time, The effect of ensuring product quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

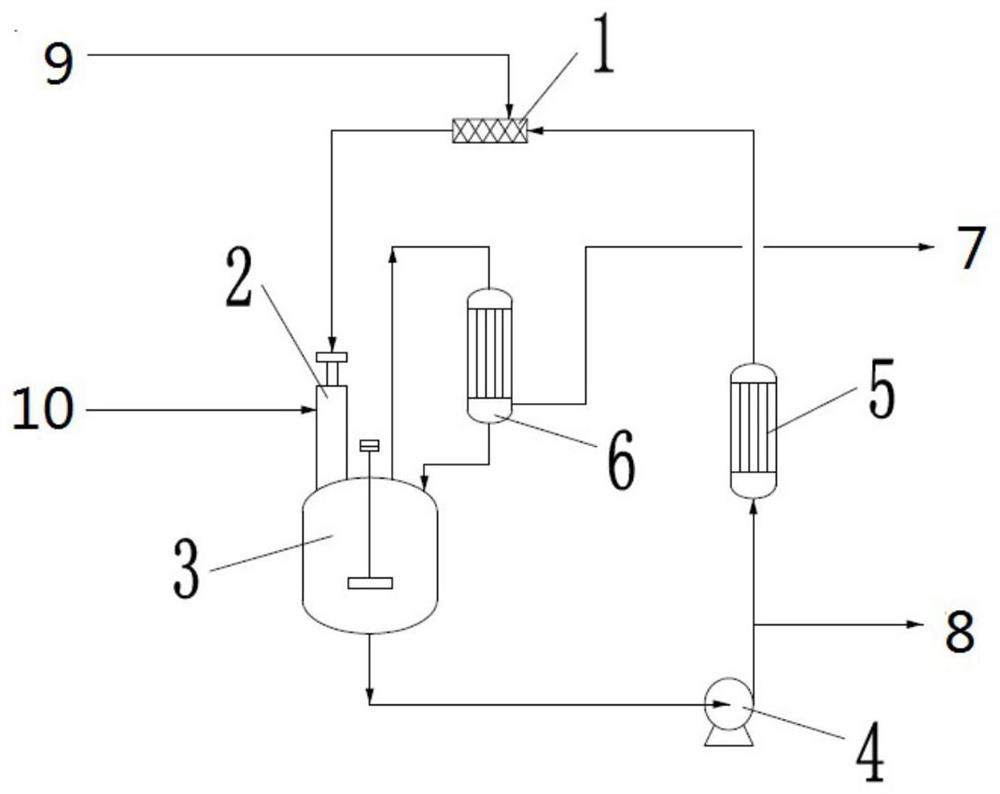

Embodiment 1

[0024] The chloropropionyl chloride complex solution 9 prepared by chloropropionyl chloride, dichloromethane and aluminum chloride has a flow rate of 367.1kg / h, and is mixed uniformly with the Friedel-Crafts reaction circulating liquid in a static mixer 1 to obtain a mixed solution; Liquid and 111.2kg / h of isobutylbenzene 10 enter jet reactor 2 to react simultaneously, wherein mixed liquid is used as jet reactor 2 active flow, and isobutylbenzene 10 is used as jet reactor 2 driven flow; Jet reactor 2 and band The stirred Friedel-Crafts reactor 3 is connected to the top, and the material enters the Friedel-Crafts reactor 3 for further reaction, and the reaction temperature in the reactor is controlled at 5°C; the ketone solution is discharged through the circulation pump 4, wherein the feed liquid with a flow rate of 4000kg / h is circulated After the cooler 5 is cooled to -2°C, it enters the static mixer 1, and is mixed with the chloropropionyl chloride complex solution 9 as a ci...

Embodiment 2

[0026] This embodiment relates to the continuous production method of ibuprofen Friedel-Crafts reaction. The chloropropionyl chloride complex solution 9 prepared by chloropropionyl chloride, dichloromethane and aluminum chloride has a flow rate of 367.1kg / h, and is mixed uniformly with the Friedel-Crafts reaction circulating liquid in a static mixer 1 to obtain a mixed solution; Liquid and 111.2kg / h of isobutylbenzene 10 enter jet reactor 2 to react simultaneously, wherein mixed liquid is used as jet reactor 2 active flow, and isobutylbenzene 10 is used as jet reactor 2 driven flow; Jet reactor 2 and band The stirred Friedel-Crafts reactor 3 is connected to the top, and the material enters the Friedel-Crafts reactor 3 for further reaction, and the reaction temperature in the reactor is controlled at 10°C; the ketone solution is discharged through the circulating pump 4, and the feed liquid with a flow rate of 2000kg / h is circulated After the material cooler 5 is cooled to 0°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com