Modified polybutadiene resin as well as preparation method and application thereof

A polybutadiene resin and modification technology, which is applied in the field of modified polybutadiene resin and its preparation, can solve the problems that printed circuit boards cannot meet the performance requirements of electronic appliances, etc., and achieve the improvement of glass transition temperature, Ease of product separation and the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] According to a second aspect of the present invention, a kind of preparation method of above-mentioned modified polybutadiene resin is provided, comprising the following steps:

[0074] Under alkaline conditions, the polybutadiene resin and the halogenated aromatic ring compound are catalyzed by a heterogeneous catalyst to react in the solution, and post-treated to obtain a modified polybutadiene resin;

[0075] Wherein, polybutadiene resin comprises the structure represented by following general formula (2):

[0076]

[0077] Wherein, Y is selected from integers ranging from 1 to 50, for example, Y may be selected from 1, 5, 10, 15, 20, 25, 30, 35, 40, 45, 50;

[0078] M is an integer selected from 1 to 50, for example, M may be selected from 1, 5, 10, 15, 20, 25, 30, 35, 40, 45, 50;

[0079] The halogenated aromatic ring compounds of the present invention include structures represented by the following general formula (3):

[0080] X-R 1 (3);

[0081] Wherein,...

Embodiment 1

[0105] A preparation method of modified polybutadiene resin, comprising the following steps:

[0106] In a dry and clean 100mL flask, drop into polybutadiene resin (PB resin) 5g (0.0833mol), 4-bromobenzophenone 8.7g (0.0333mol), palladium carbon catalyst 2.61g, triethylamine 6.74g ( 0.0666mol) and N,N-dimethylformamide 36.00g, under a nitrogen atmosphere, reflux at 130°C for 16h, track the reaction process by thin layer chromatography (TLC), the PB resin of this embodiment has the following structure:

[0107]

[0108] Among them, Y is 5;

[0109] M is 55;

[0110] After the reaction was completed, the reaction solution was cooled to room temperature, and the insoluble impurities in the reaction solution including catalyst were removed by high-speed centrifugation, and then precipitated in methanol with 5 times the volume of the reaction solution, stirred for 30 minutes, and suction filtered to obtain an off-white solid;

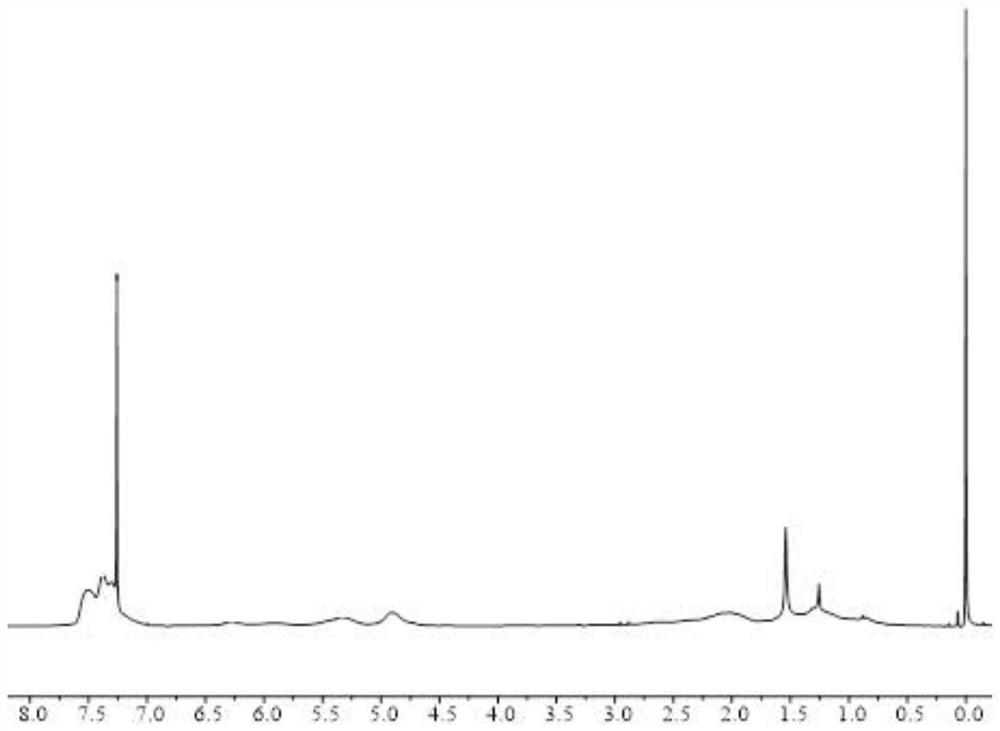

[0111] Dissolve the obtained off-white solid in t...

Embodiment 2

[0114] The difference between this example and Example 1 is that in this example, 5.27 g (0.0666 mol) of pyridine is used to replace the triethylamine in Example 1, and 36 g of N-methylpyrrolidone is used to replace the N,N-diethylamine in Example 1. Methylformamide, in this example, reflux at 145°C for 18 hours under a nitrogen atmosphere, other reaction raw materials, their dosages, and reaction steps are the same as in Example 1, to obtain a modified polybutadiene resin;

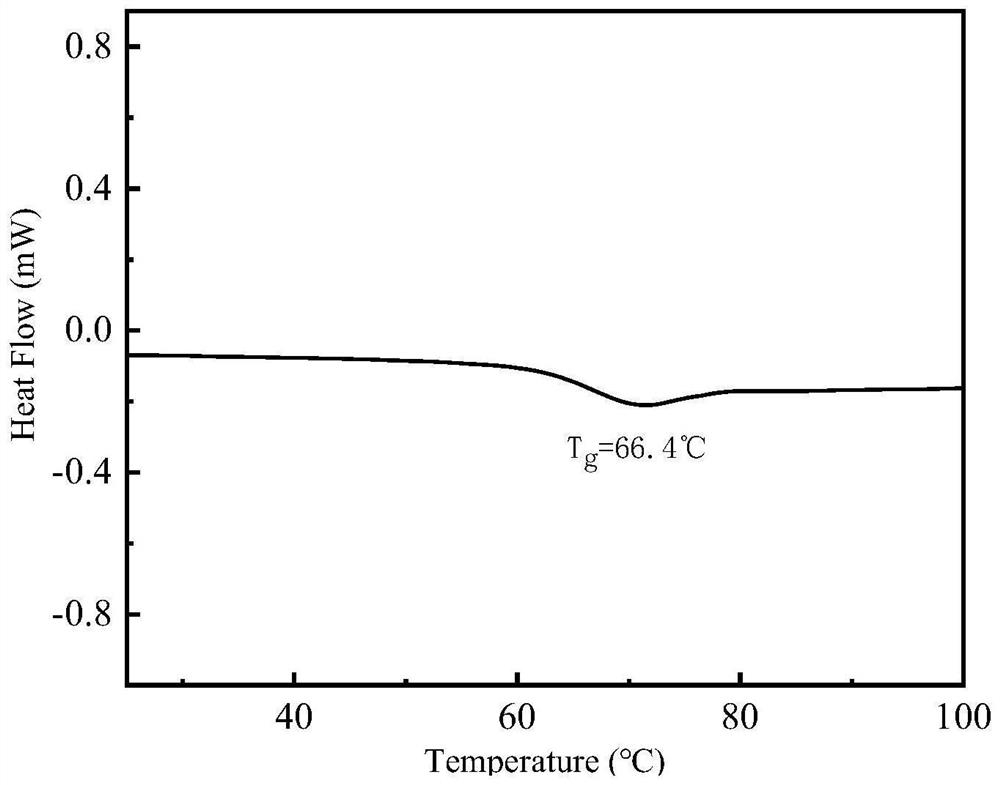

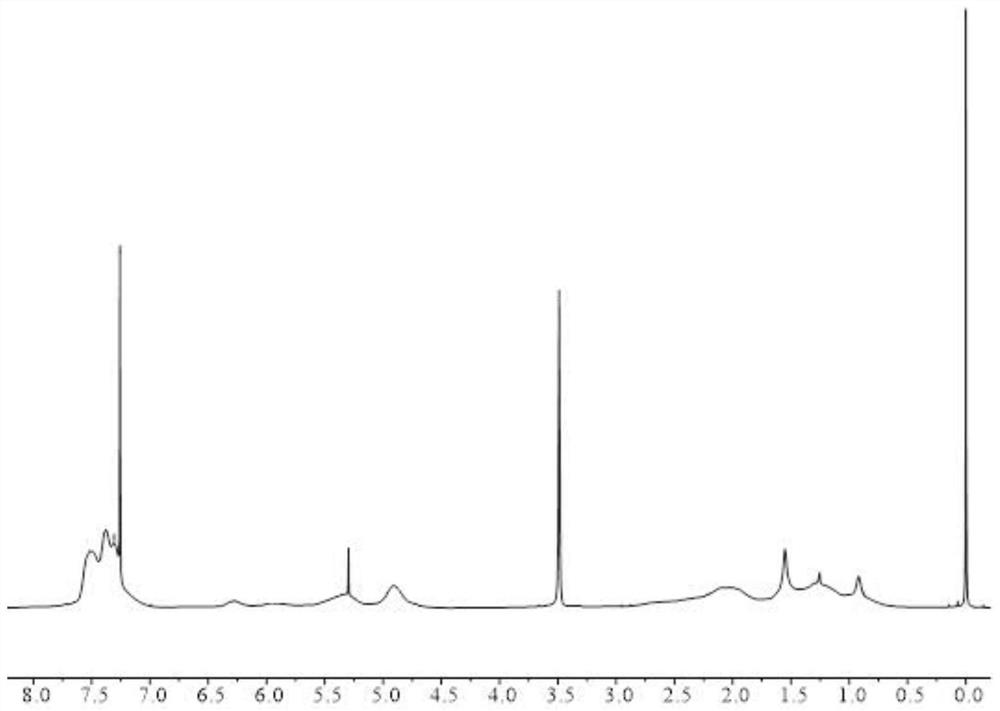

[0115] The characterization and test method of the present embodiment modified polybutadiene resin are the same as embodiment 1, and the proton nuclear magnetic spectrum (abscissa ppm) that obtains is as image 3 As shown, the peak corresponding between 7.25~7.75ppm is the characteristic peak of the benzene ring group, which proves that the grafting reaction of the present embodiment is successful; DSC test result is as follows Figure 4 Shown, showed that the glass transition temperature of the modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com