Sintering energy-saving and emission-reducing method for coupling injection of micro-fine particle biomass fuel and hydrogen-containing fuel gas

A biomass fuel, energy-saving and emission-reduction technology, which is applied in the field of sintering energy-saving and emission-reduction coupled injection of fine-grained biomass fuel and hydrogen-containing gas, can solve problems such as the limited reduction ratio of solid fossil fuels, and achieve reduced consumption and high-efficiency conversion , the effect of efficient and sufficient supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

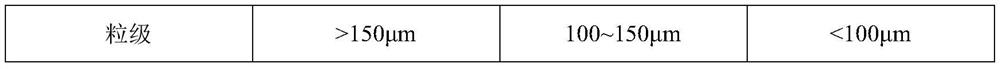

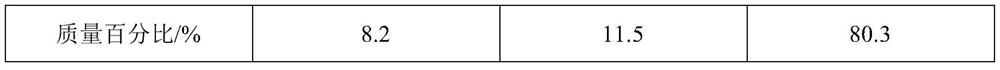

[0029]According to the mass ratio of mixed iron ore 64.2%, dolomite 2.3%, limestone 1.5%, quicklime 4.0%, returned ore 24.7%, and coke powder 3.3%, the materials are mixed and granulated, and the mixture is distributed to the sintering table Car, ignite for 1 min at a temperature of 1050±50°C and a negative pressure of -5kPa, and then sinter at a negative pressure of -14kPa. Use an infrared thermal imager to divide the material surface between the ignition furnace and the temperature of the sintering waste gas to rise, and spray fine-grained sawdust with a calorific value equal to that of 2.0% natural gas by volume to the area where the temperature of the material surface is >500°C. Its particle size composition is shown in Table 1, and the injection height is 400mm; the micro-grained sawdust with the calorific value equal to the volume percentage concentration of 1.0% natural gas is sprayed into the area where the temperature of the material surface is 300-500°C, and the injec...

Embodiment 2

[0031] According to the mass ratio of mixed iron ore 64.3%, dolomite 2.3%, limestone 1.5%, quicklime 4.0%, returned ore 24.7%, coke powder 3.2%, after the materials are mixed and granulated, the mixture is distributed to the sintering table Car, ignite for 1 min at a temperature of 1050±50°C and a negative pressure of -5kPa, and then sinter at a negative pressure of 14kPa. Use an infrared thermal imager to divide the material surface between the ignition furnace and the temperature of the sintering waste gas to rise, and spray fine-grained sawdust with a calorific value equal to that of 2.5% natural gas by volume to the area where the temperature of the material surface is >500°C. Its particle size composition is shown in Table 1, and the injection height is 400mm; the fine-grained sawdust with the calorific value equal to the volume percentage concentration of 1.3% natural gas is sprayed into the area where the temperature of the material surface is 300-500 °C, and the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com