Composite material of conductive slip ring and preparation method thereof

A composite material and conductive slip ring technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of insufficient friction and wear performance and electrical conductivity of copper-based materials, so as to avoid insufficient sintering, improve bearing capacity and chemical stability sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

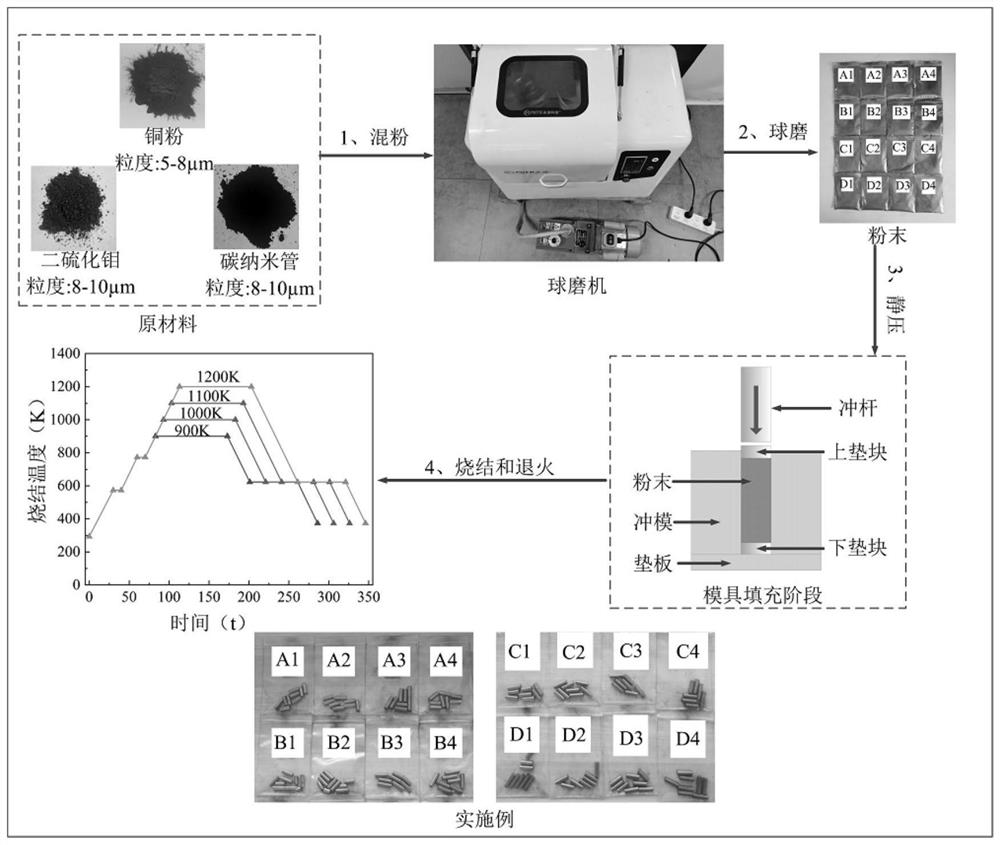

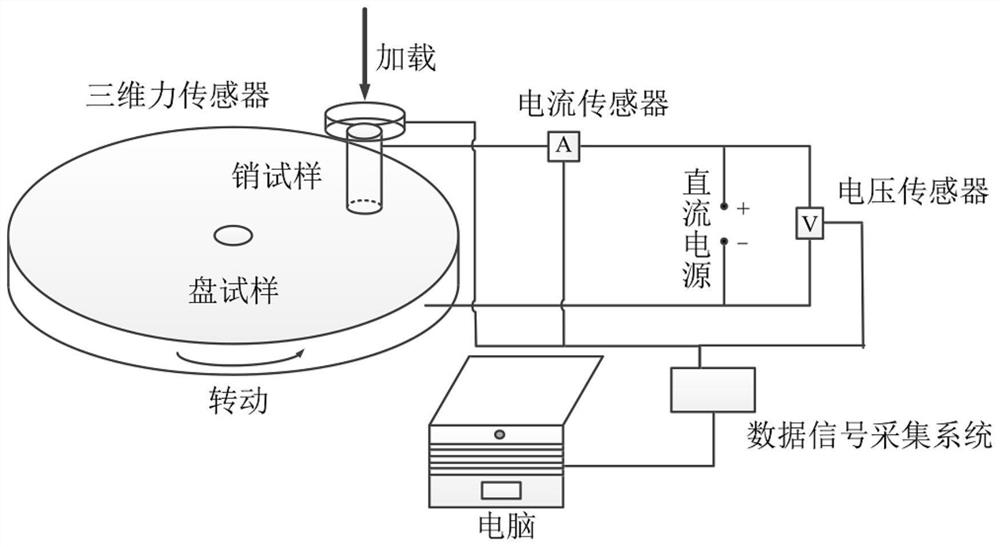

[0026] The present invention will be further described below with reference to the accompanying drawings.

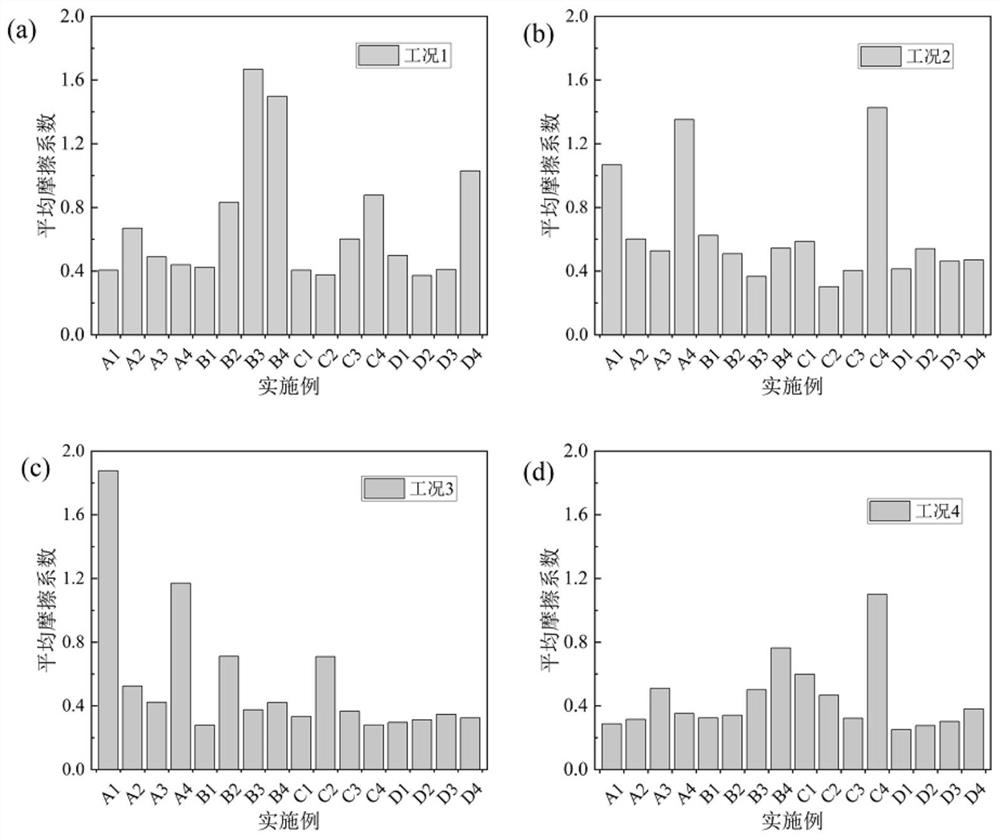

[0027] Different samples are prepared by using the composite material of the present invention, and the copper-based composite material includes 5-20% of molybdenum disulfide, 0-1% of carbon nanotubes and the balance of copper powder in terms of mass fraction. Table 1 shows the carbon nanotubes, molybdenum disulfide mass fraction and sintering temperature of specific examples A1-A4, B1-B4, C1-C4, D1-D4.

[0028] Table 1

[0029]

[0030] Among them, the purity of copper powder is more than 99.9%, and the particle size is 5-8μm; the purity of molybdenum disulfide powder is more than 99%, and the particle size is 10μm; the purity of carbon nanotubes is more than 95%, the inner diameter is 3-5nm, and the outer diameter is 8-15nm. The length is 3-12 μm.

[0031] The steps for preparing the test pieces of the various embodiments include:

[0032] Mixing powder: accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electric noise | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com