High-dispersity nanocrystalline manganese dioxide electrolysis additive as well as preparation method and application thereof

A technology of manganese dioxide and high dispersion, which is applied in electrolysis process, electrolysis components, etc., can solve the problem that the bead mill system cannot meet the requirements of powder grinding particle size reaching nanometer level, restricts flexible production arrangements, and cannot continuously feed production etc. to achieve the effect of shortening the grinding time, increasing the apparent cross-sectional area, and improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

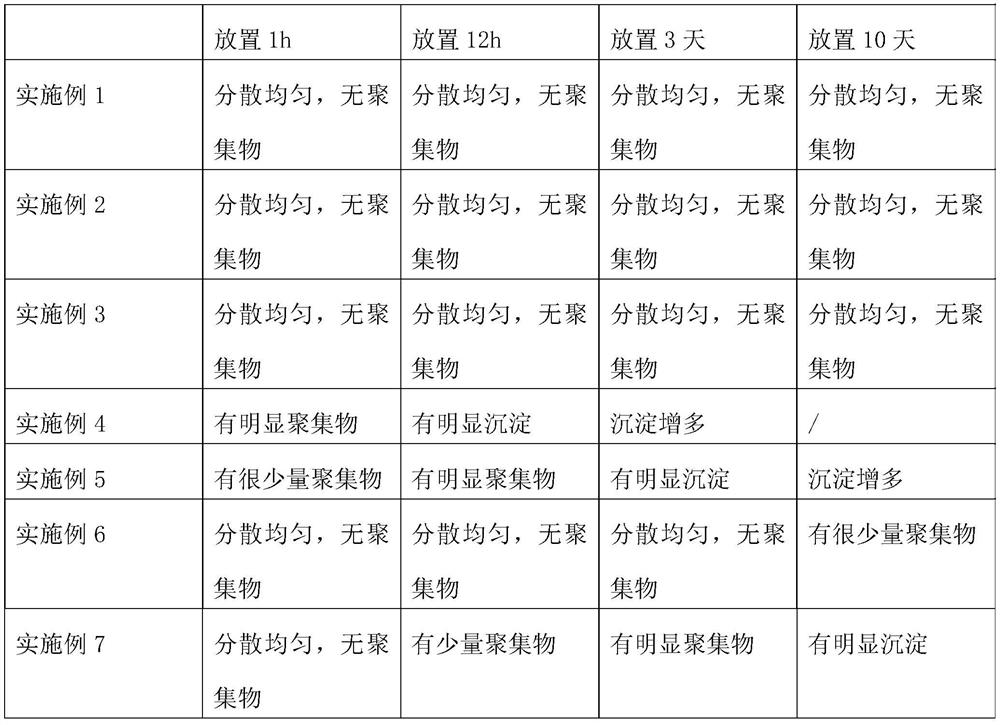

Examples

preparation example Construction

[0020] A preparation method of highly dispersed nanocrystalline manganese dioxide electrolytic additive, comprising the following steps:

[0021] (1) Put the manganese dioxide powder, water and active dispersant surfynol CT-231 into the container in a certain proportion, heat up to 40-60° under stirring, keep the temperature for at least 20min, and obtain the slurry dispersion;

[0022] (2) Transfer the slurry dispersion to a bead mill for grinding until the part of the slurry dispersion with a particle size of 50-150nm reaches more than 50%, then separate it by a centrifuge, and transfer the separated light liquid to in transit containers;

[0023] (3) Add polyvinylpyrrolidone into the transfer container, stir and disperse evenly, and obtain a highly dispersible nanocrystalline manganese dioxide electrolytic additive.

[0024] In some preferred embodiments, the active dispersant surfynol CT-231 is added in an amount of 3-6% of the mass of the manganese dioxide powder.

[00...

Embodiment 1

[0032] (1) Put 400kg of bagged manganese dioxide secondary products, 2615L of water and 12kg of active dispersant surfynol CT-231 into the stirring tank, heat up to 40° under stirring, keep the temperature for at least 50min, and obtain the slurry dispersion;

[0033] (2) Transfer the slurry dispersion to a bead mill for grinding, the grinding medium is zirconia beads, the particle size of zirconia beads is 0.5mm-2.0mm, the filling rate is 60%-80%, and the grinding Until the part of the slurry dispersion particle size 50-150nm reaches more than 50%, it is separated by a five-stage centrifugal separator, and the light liquid (slurry with a smaller particle size) is separated from the heavy liquid (slurry with a larger particle size). The light liquid separated by each stage flows to the next stage, and the heavy liquid is pumped back to the bead mill for circular grinding. The light liquid separated by the fifth stage is the qualified feed liquid, and the separated light liquid ...

Embodiment 2

[0036] (1) Put 400kg bagged manganese dioxide secondary product, 2580L water and active dispersant surfynol CT-231 into the stirring tank, heat up to 50 ° under stirring, keep warm for 30min, and obtain slurry dispersion;

[0037] (2) Transfer the slurry dispersion to a bead mill for grinding, the grinding medium is zirconia beads, the particle diameter of zirconia beads is 0.5mm-2.0mm, and the filling rate is 60%-80%, until The part of slurry dispersion with a particle size of 50-150nm reaches more than 50%, and then separated by a centrifuge, the separated light liquid is transferred to a transfer container, and the separated heavy liquid is sent back to the bead mill for secondary grinding;

[0038] (3) Add polyvinylpyrrolidone into the transfer tank, stir and disperse evenly, and obtain a highly dispersible nanocrystalline manganese dioxide electrolytic additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com