Composite paper and preparation method thereof, filter stick forming paper, filter tip, tobacco product and application

A composite paper and forming paper technology, which is applied in the direction of paper forming aid addition, application, tobacco, etc., can solve the problems of ineffective utilization, etc., and achieve the improvement of sensory quality, the reduction of gas-phase free radicals and solid-phase free radicals, and the reduction of nicotine. and caffeine-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

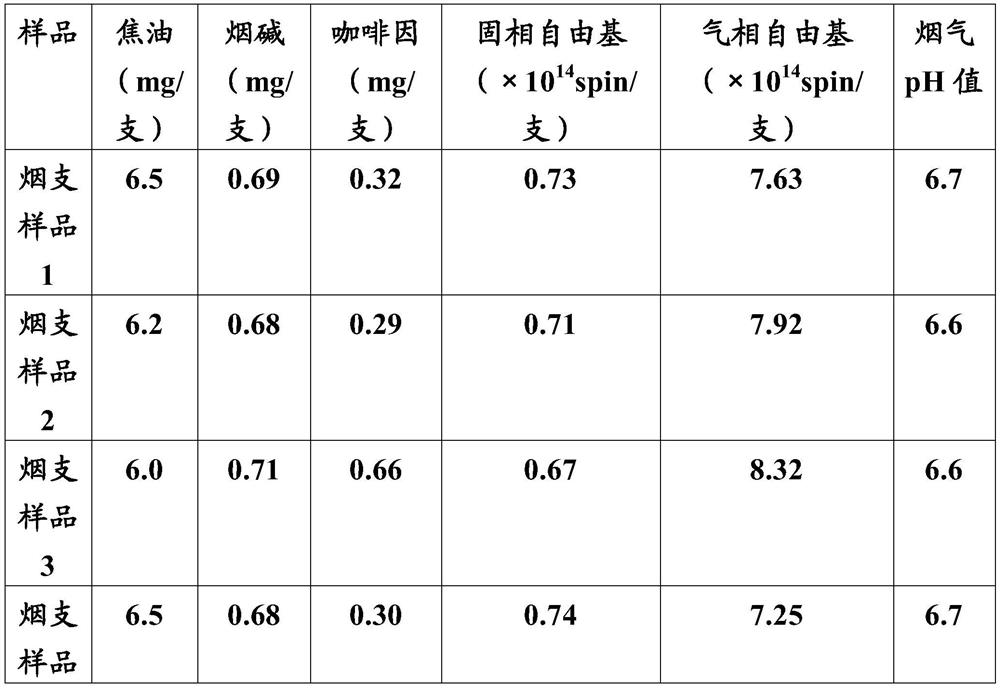

Embodiment 1

[0071] (1) Pulverize the washed Arabica coffee beans, pass through a 60-mesh sieve, and collect the sieved coffee bean powder; add 1 times the volume of 80°C water to the coffee bean powder and soak for 24 hours, filter to obtain coffee grounds;

[0072] (2) Dry the coffee grounds at 50°C until the moisture is 6.0% W / W;

[0073] (3) Grind the dried coffee grounds in a jet mill (purchased from Shandong Jingxin Powder Equipment Technology Co., Ltd., model QLMA series), pass through a 400-mesh sieve, and collect the sieved coffee grounds powder;

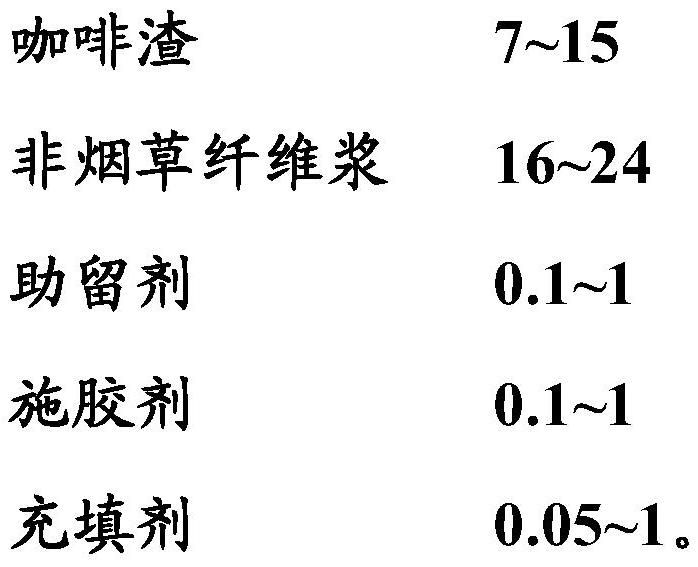

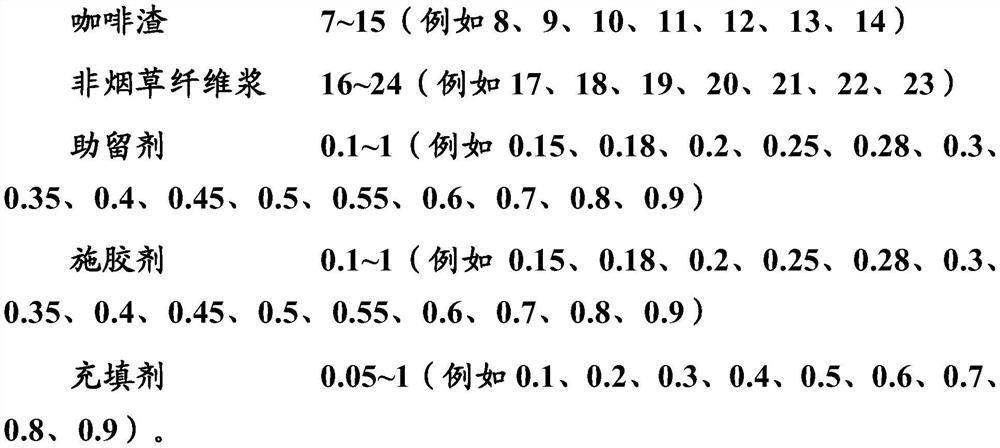

[0074] (4) Mix coffee grounds powder, coniferous wood pulp and synthetic fiber pulp evenly, then add polyacrylamide (retention aid) and alkyl ketene dimer (sizing agent) with a weight average molecular weight of 2 to 4 million Continue to mix with glass powder (filler) to obtain a mixture; wherein, the mass ratio of coffee grounds powder, coniferous wood pulp and synthetic fiber pulp is 2:2:2, polyacrylamide and alkyl ketene dimer The ...

Embodiment 2

[0081] (1) Pulverize the honey-treated Arabica coffee beans, pass through a 70-mesh sieve, and collect the sifted coffee bean powder; add 1 times the volume of 80°C water to the coffee bean powder and soak for 12 hours, filter to obtain coffee grounds;

[0082] (2) Dry the coffee grounds at 50°C until the moisture is 5.5% W / W;

[0083] (3) Grind the dried coffee grounds in a jet mill (purchased from Shandong Jingxin Powder Equipment Technology Co., Ltd., model QLMA series), pass through a 500-mesh sieve, and collect the sieved coffee grounds powder.

[0084] (4) Mix coffee grounds powder, coniferous wood pulp and synthetic fiber wood pulp evenly, then add polyoxyethylene (retention aid), styrene-maleic anhydride copolymer (sizing agent) and graphite (filler) to continue Mix evenly to obtain a mixture; wherein, the mass ratio of coffee grounds powder, softwood pulp and synthetic fiber pulp is 1:1:1, and the quality of polyoxyethylene and styrene-maleic anhydride copolymer is th...

Embodiment 3

[0091] (1) Crush the sun-treated Robusta coffee beans, pass through a 40-mesh sieve, and collect the sieved coffee bean powder; add 2 times the volume of 80°C water to the coffee bean powder and soak for 24 hours, filter to obtain coffee grounds ;

[0092] (2) Dry the coffee grounds at 60°C until the moisture is 6.5% W / W;

[0093] (3) Grind the dried coffee grounds in a jet mill (purchased from Shandong Jingxin Powder Equipment Technology Co., Ltd., model QLMA series), pass through a 600-mesh sieve, and collect the sieved coffee grounds powder;

[0094] (4) Mix coffee grounds powder, coniferous wood pulp and synthetic fiber wood pulp evenly, then add cationic polyacrylamide (retention aid) with a weight average molecular weight of 5 to 7 million, carboxymethyl cellulose (sizing agent) and Diatomaceous earth (filler) continues to mix uniformly, obtains mixture; Wherein, the mass ratio of coffee grounds powder, coniferous wood pulp and synthetic fiber pulp is 5:5:5, the mass ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap