Pull-type straw biomass particle making machine

A biomass granulation and traction technology, which is applied in the extrusion granulation of raw materials, die extrusion granulation, presses, etc., can solve the problems of unfavorable miniaturization of roller granulation, and meet the requirements of reducing equipment power, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

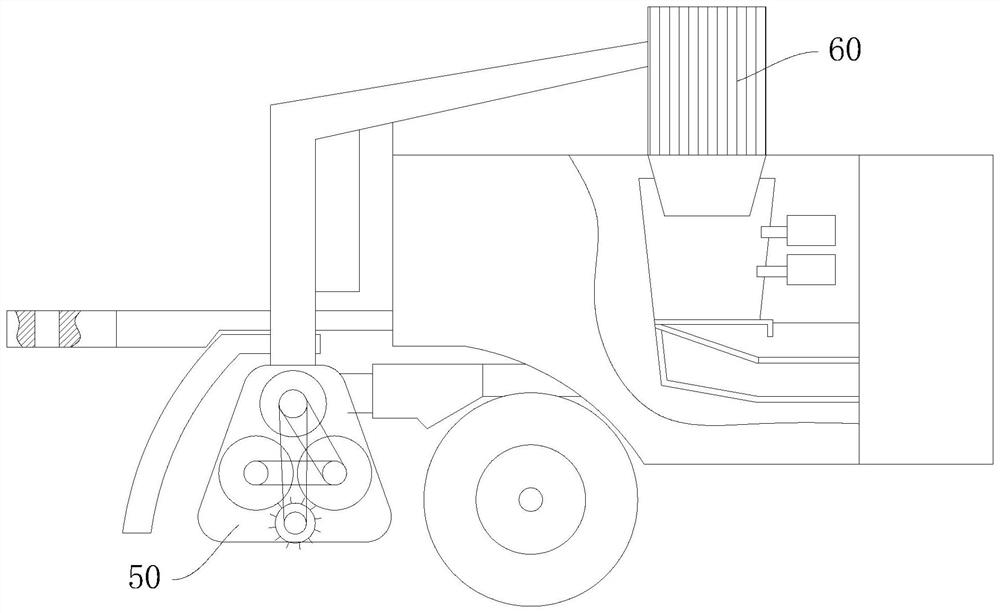

[0032] like figure 1 as shown, figure 1 It is a schematic diagram of the overall structure, which is moved by a traction mechanism. The front end has a straw picking and processing device 50 for picking up and crushing straw. The frame is also equipped with a straw storage room 60 and a straw conveying device. The conveying device in the prior art conveys to the straw storage room, and the straw conveying device sends the straw to the molding device. Among them, the straw storage room can be equipped with a dust removal device according to actual needs to remove the dust. It is worth noting that this part of the content is all existing technology, and its principle adopts the straw picking and pulverizing machine on the market.

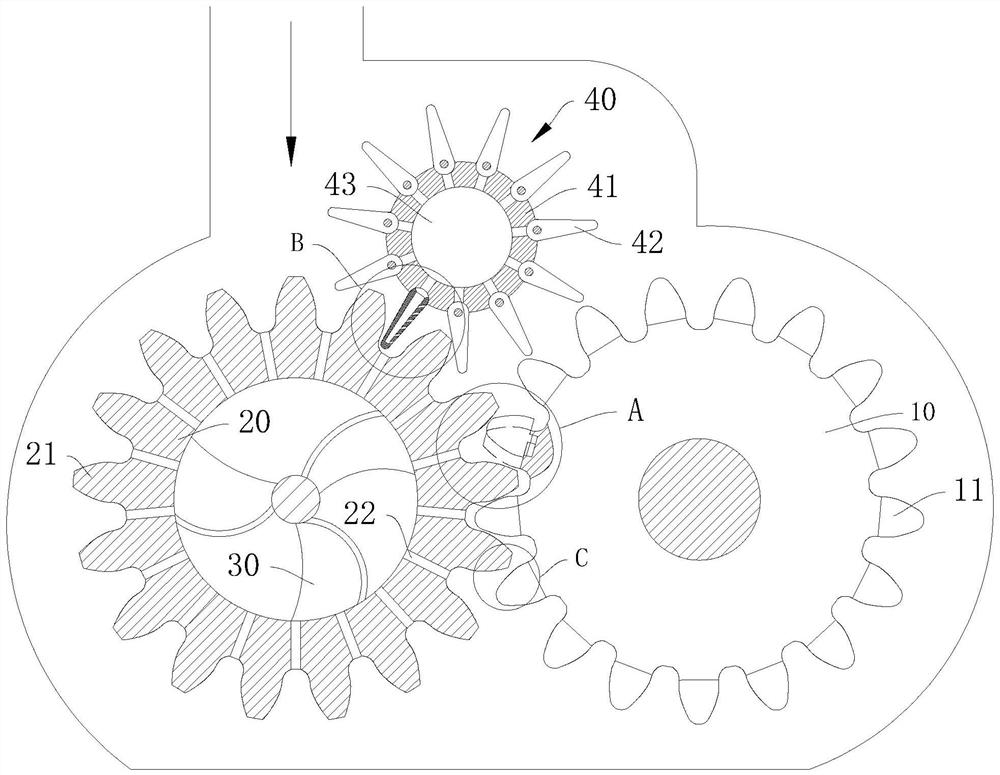

[0033] like figure 2As shown, a traction-type straw biomass granulator provided by the embodiment of the present invention has a shell, and the shell has a feed port, and the feed port corresponds to the output of the above-mentioned crushing devi...

Embodiment 2

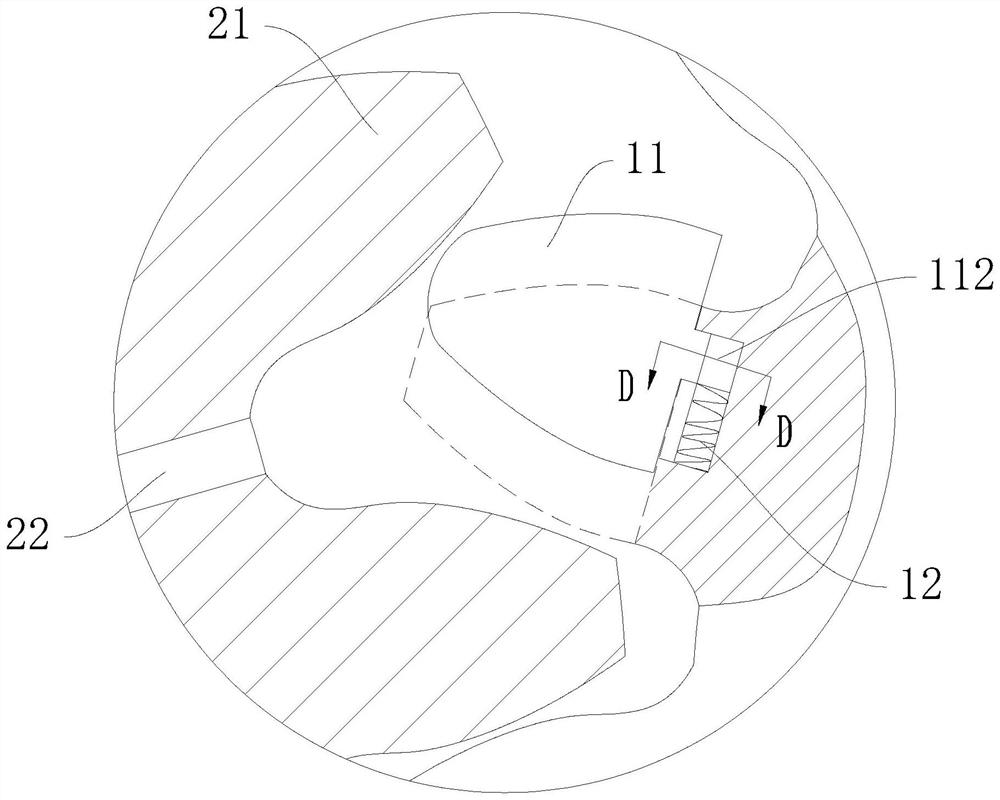

[0041] Due to the limited pre-extrusion of the material and the limited delivery volume of the material by the offset of the sliding tooth 11, for loose straw, it can be squeezed in advance to form a dense structure, which can effectively increase the effective actual delivery volume of a single time, so in the implementation On the basis of Example 1, this embodiment also includes a preloading device 40 and a second driving device, such as figure 2 and Figure 4 As shown, the preloading device 40 includes a base wheel 41 and several preloading rods 42, the number of the preloading rods 42 is greater than the number of the drive teeth 21, and several preloading rods 42 are evenly distributed on the peripheral side of the base wheel 41 in the circumferential direction. The rod 42 is rotatably mounted on the base wheel 41 through a torsion spring. Specifically, the preload rod 42 has a plate-like structure, and its two ends are respectively rotatably mounted on the base wheel 4...

Embodiment 3

[0045] When the green straw is recycled, the water content in the straw is relatively high, and the straw will generate a lot of heat due to the gear meshing and the rapid impact and friction of the pre-compression rod 42, which will evaporate the water, and more water vapor will cause intermolecular The distance increases, which affects the conduction of heat and reduces the cohesive force of the straw. Due to the limited internal space of the granulator, the water vapor cannot be discharged in time, and the evaporated water vapor forms a high pressure, which leads to volume expansion, increases the space it occupies, and "steam blockage" occurs. The ejection in the forming hole 22 produces the phenomenon of "blasting".

[0046] Therefore, on the basis of the second embodiment, the present embodiment also includes a vacuum pump, such as Figure 4 As shown, the base wheel 41 is provided with a dehumidification hole 43 with an open end, and the vacuum pump penetrates into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com