Method for extracting protein from excess sludge

A technology for excess sludge and protein, applied in the field of protein extraction, can solve the problems affecting the quality of the final product, affecting the protein concentration and efficiency in the extracted sludge, and achieve the effects of reducing energy consumption, avoiding protective effects, and increasing protein concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

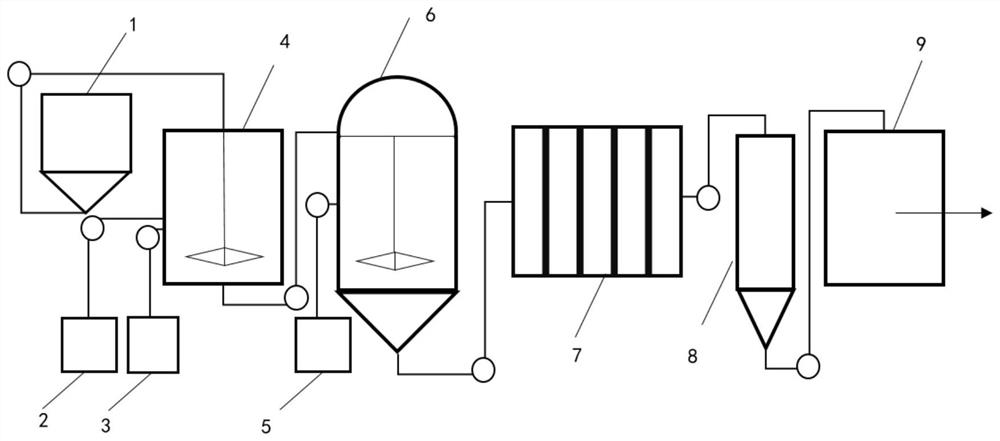

Image

Examples

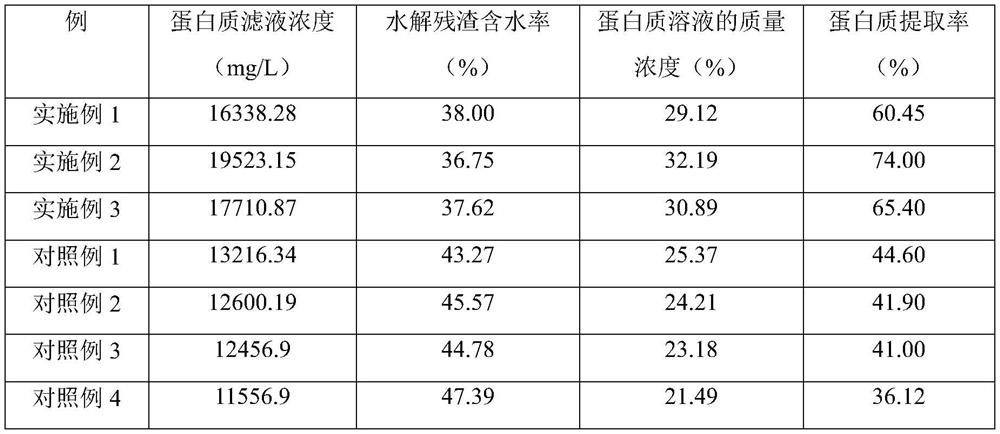

Embodiment 1

[0053] A method for extracting protein from excess sludge, comprising the steps of:

[0054] (1) Adjusting the sludge concentration: adding water to the remaining sludge to adjust to obtain a sludge solution with a sludge concentration of 120g / L;

[0055] (2) Specific enzymolysis: mix the sludge solution in step (1) with the compound enzyme preparation, carry out enzymolysis at 37°C and 80rpm for 2 hours, and obtain the mixed solution after enzymolysis; wherein, the amount of the compound enzyme preparation is relatively The mass percentage in the sludge solution is 2%; the compound enzyme preparation is a compound enzyme composed of glucuronidase and lipase with a mass ratio of 1:1, and the glucuronidase is α-starch with a mass ratio of 3:1 Enzyme, beta-amylase;

[0056] (3) Alkali-thermal hydrolysis: pressurize the enzymolyzed mixed solution obtained in step (2) to 0.21MPa, adjust the pH to 11 with NaOH, and perform hydrolysis at 120°C and 150rpm for 1.5h to obtain the hydr...

Embodiment 2

[0059] Adjust the mass ratio of glucuronidase and lipase in the compound enzyme preparation in step (2) of Example 1 to 3:1, and keep the others consistent with Example 1 to obtain a protein solution.

Embodiment 3

[0061] Adjust the mass ratio of glucuronidase and lipase in the compound enzyme preparation in step (2) of Example 1 to 5:1, and keep the others consistent with Example 1 to obtain a protein solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com