Low-odor heat-resistant straw biodegradable material and preparation method thereof

A biodegradable material and low-odor technology, applied in the field of low-odor heat-resistant straw biodegradable materials and its preparation, can solve the problems of low heat resistance of alloy materials, unsatisfactory, poor heat resistance, etc., to improve strength and reduce odor , Improve the effect of heat resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

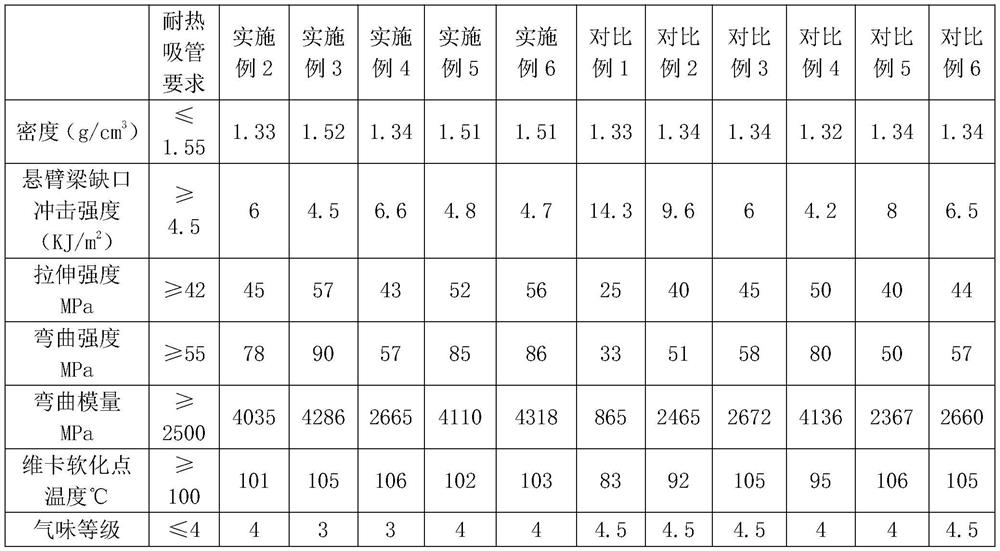

Examples

Embodiment 1

[0043] The low-odor heat-resistant straw biodegradable material in this embodiment mainly includes the following components in parts by mass:

[0044] Polylactic acid: 30-50 parts;

[0045] Polybutylene succinate: 30-50 parts;

[0046] Inorganic powder: 10-30 parts;

[0047] Compound antioxidant: 0.4-0.8 parts;

[0048] Lubricant: 0.3-0.8 parts;

[0049] Compound deodorant: 0.2-0.5 parts;

[0050] Chain extender: 0.1-0.5 parts.

[0051] The straw is formed by extrusion, so the polylactic acid in this example is an extrusion grade with a melt index range of 3-8g / min to ensure the stability of the molding; PBS is an extrusion grade with a melt index range of 3-8g / min. 8g / min, to ensure the stability of molding;

[0052] The inorganic powder is one or more of talcum powder, calcium carbonate, barium sulfate and wollastonite. The addition of inorganic powder can increase the strength and reduce the cost;

[0053] The lubricant is one or more of vinyl bis stearamide, polysil...

Embodiment 2

[0066] The low-odor heat-resistant straw biodegradable material in this embodiment mainly includes the following components in parts by mass:

[0067] Polylactic acid: 50 parts;

[0068] PBS: 38.7 copies;

[0069] Inorganic powder: 10 parts;

[0070] Compound antioxidant: 0.6 parts;

[0071] Lubricant: 0.3 parts;

[0072] Compound deodorant: 0.3 parts;

[0073] Chain extender: 0.1 parts.

[0074] The polylactic acid in this example is extrusion grade, with a melt index range of 3-8g / min; PBS is extrusion grade, with a melt index range of 3-8g / min;

[0075] The inorganic powder is talcum powder; the lubricant is one or more of vinyl bis stearamide, polysiloxane, calcium stearate and ethylene bis stearamide; the compound antioxidant is hindered phenol One or more of antioxidants and phosphite lipid antioxidants; the compound deodorant is a compound of porous nano-silica and organic phytoalcohol; the chain extender is an epoxy functional group Types of.

[0076] The above...

Embodiment 3

[0078] The low-odor heat-resistant straw biodegradable material in this embodiment mainly includes the following components in parts by mass:

[0079] Polylactic acid: 30 parts;

[0080] PBS: 38.4 copies;

[0081] Inorganic powder: 30 parts;

[0082] Compound antioxidant: 0.4 parts;

[0083] Lubricant: 0.3 parts;

[0084] Compound deodorant: 0.5 parts;

[0085] Chain extender: 0.4 parts.

[0086] The polylactic acid in this example is extrusion grade, with a melt index range of 3-8g / min; PBS is extrusion grade, with a melt index range of 3-8g / min;

[0087] The inorganic powder is talcum powder; the lubricant is one or more of vinyl bis stearamide, polysiloxane, calcium stearate and ethylene bis stearamide; the compound antioxidant is hindered phenol One or more of antioxidants and phosphite lipid antioxidants; the compound deodorant is a compound of porous nano-silica and organic phytoalcohol; the chain extender is an epoxy functional group Types of.

[0088] The above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com