Wave-absorbing adhesive film and preparation method thereof

A technology of adhesive film and adhesive film layer, which is applied in the field of wave-absorbing materials, can solve the problems of complex wave-absorbing film process and poor matrix strength of wave-absorbing film, so as to reduce the number of processes, reduce the difficulty of operation, and enhance the bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

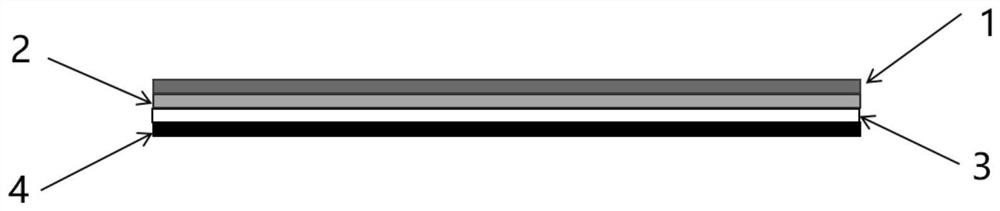

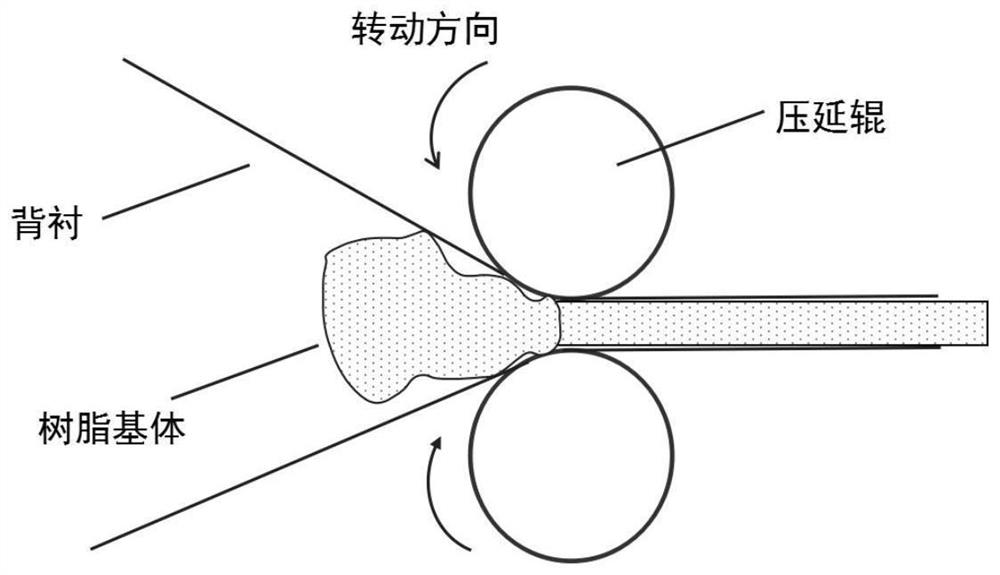

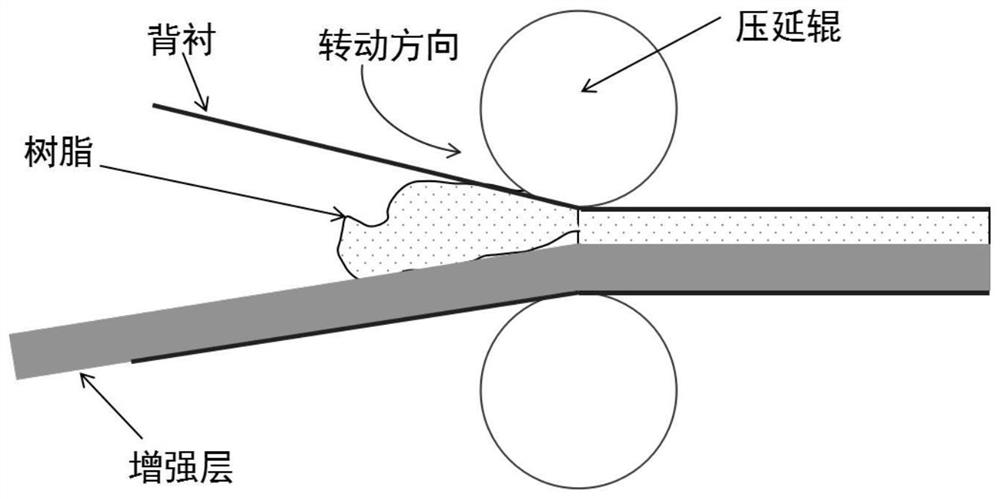

[0061] In this example, the wave-absorbing adhesive film is prepared by the following method, and the structure of the prepared wave-absorbing adhesive film is as follows figure 1 Shown: including absorbing layer 1, reinforcing layer 2, adhesive film layer 3, and backing 4. The specific preparation process is as follows figure 2 , image 3 and Figure 4 shown.

[0062] (1) Put 3180 epoxy resin into the open mill and masticate for 5 minutes, the temperature of the open mill is set to 50°C, the speed of the front roll is set to 18rpm, and the speed of the back roll is set to 12rpm;

[0063] (2) Load glass fiber fabric / 3180 resin prepreg with PET release layer and PET release film (release layer) into the calender, place the prepreg and release film oppositely, Add the 3180 resin matrix plasticized in step (1), set the temperature of the calender to 80°C, the roller speed of the calender to 2m / min, and set the gap between the two rollers to 0.35mm, and calender to obtain a ...

Embodiment 2

[0068] In this example, the wave-absorbing adhesive film was prepared by the following preparation method

[0069] (1) Put 3180 epoxy resin into the open mill and masticate for 10 minutes, the temperature of the open mill is set to 100°C, the speed of the front roll is set to 16rpm, and the speed of the back roll is set to 10rpm;

[0070] (2) Load the carbon fiber textile / 3180 resin prepreg with PET release layer and PET release film into the calender, place the prepreg and the release film opposite, and add in step (1) The plasticized 3180 resin matrix, the temperature of the calender is set to 70°C, the roller speed of the calender is 7m / min, and the gap between the two rollers is set to 0.38mm, and calendered to obtain an intermediate with a backing, an adhesive film layer, and a reinforcing layer ;

[0071] (3) Mix the wave-absorbing slurry evenly in a reaction kettle equipped with a stirring paddle, and the specific content is:

[0072] Methanol 60%, ZH-40 magnetic abso...

Embodiment 3

[0075] In this example, the wave-absorbing adhesive film was prepared by the following preparation method

[0076] (1) Put 3180 epoxy resin into the open mill and masticate for 40 minutes, the temperature of the open mill is set to 20°C, the speed of the front roll is set to 16rpm, and the speed of the back roll is set to 10rpm;

[0077] (2) Load the aramid fiber textile / 3180 resin prepreg and PET release film with PET release layer into the calender, place the prepreg and release film oppositely, add step (1) The 3180 resin matrix that has been plasticized in ) is set at 100°C for the calender, the roller speed of the calender is 5m / min, and the gap between the two rollers is set at 0.35mm. Intermediate;

[0078] (3) Mix the wave-absorbing slurry evenly in a reaction kettle equipped with a stirring paddle, and the specific content is:

[0079] Toluene 50%, conductive carbon black 22.5%, 3180 resin 22.5%, fatty alcohol polyoxyethylene ether 5%;

[0080] (4) Lay the intermed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com