Method for reducing ethyl carbamate in fermented food by synthesizing leavening agent

A starter and Lactobacillus fermentum technology are applied in the field of synthesizing starter to reduce urethane in fermented food, and can solve problems such as difficulty in regulating urea metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

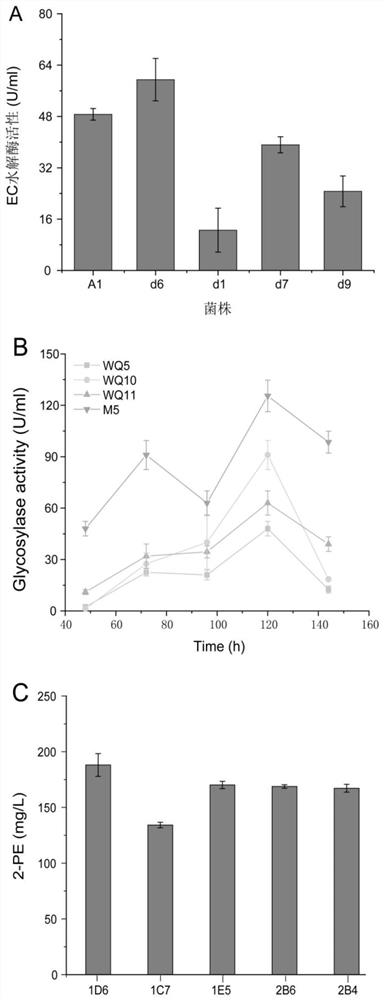

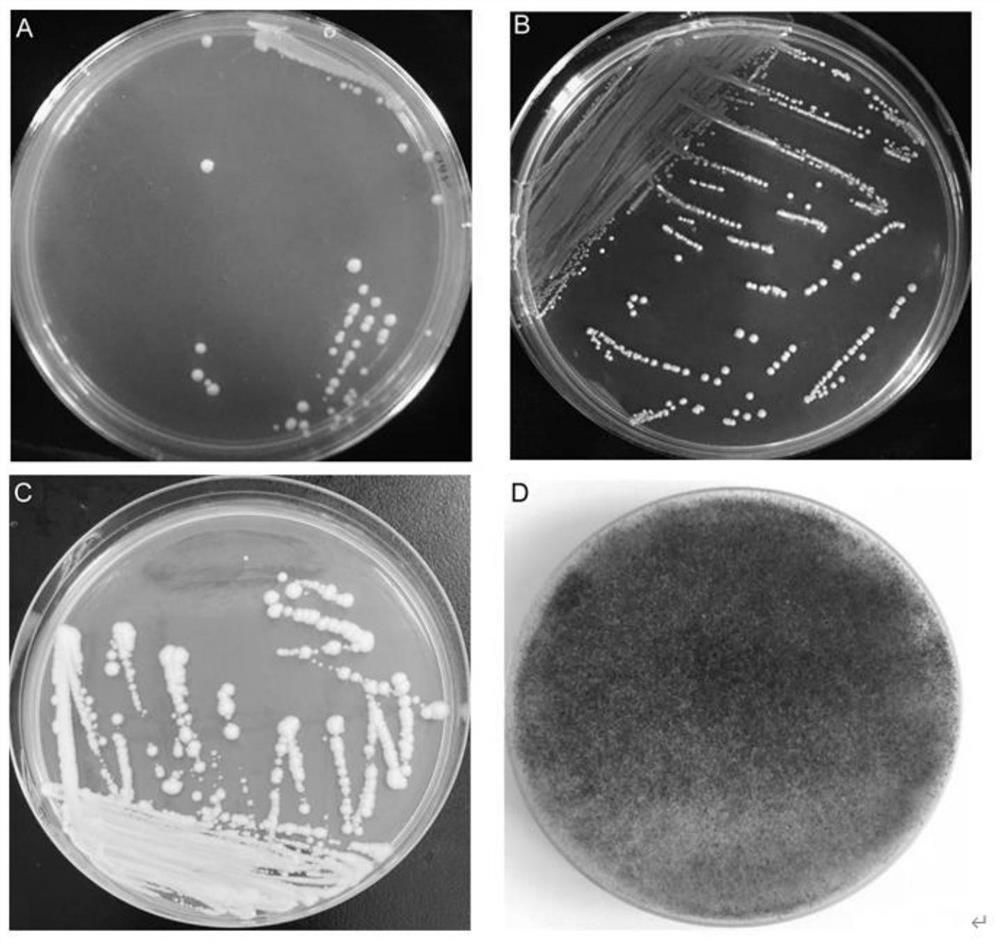

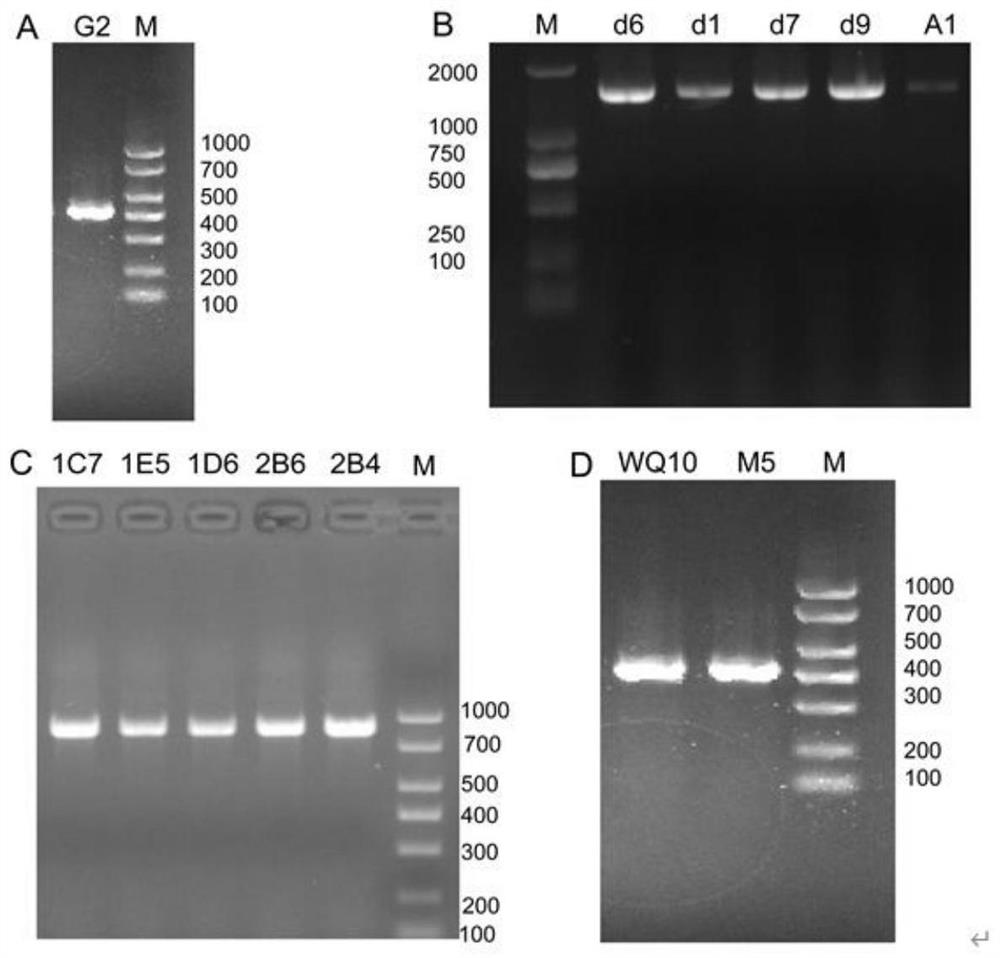

[0080] Example 1: Screening and isolation of Saccharomyces cerevisiae G2

[0081] Pre-screening: Weigh 1g of yellow rice wine fermented mash sample into a sterile EP tube, mix thoroughly with 1mL of sterile saline, dilute to an appropriate multiple, take 100μL, and spread on YNB solid medium containing urea as the only nitrogen source , placed in a constant temperature incubator at 30°C and cultivated until a single colony grows on the plate, and picked by QPix420 biological screening system or manually.

[0082] Primary screening: Use the microbial screening system QPix420 or manual selection to transfer a single colony on the pre-screening plate to a 48-well plate containing the primary screening medium, and then culture it in an orifice shaker at 30°C and 220r / min After 48h, centrifuge the 48-well plate at 3500r / min for 5min, take 80μL of the supernatant in a 96PCR plate, add 20μL of diacetylmonoxime thiamine and 100μL of ferric ammonium phosphate solution, react at 100°C f...

Embodiment 2

[0084] Embodiment 2: Screening and isolation of Rhizopus oryzae (Rhizopus oryzae) M5

[0085] Weigh 1g of rice wine fermented mash and put it in a sterile EP tube, take 1mL of sterile saline and mix well, dilute to an appropriate multiple, take 100μL and spread it on the PDA culture, and cultivate it in a constant temperature incubator at 28°C for 2-3 days. By measuring the glucoamylase activity in PDA, the strains with high glucoamylase activity were screened out, and the strains were preserved at 4°C.

[0086] Finally, a strain of mold M5 was obtained.

Embodiment 3

[0087] Embodiment 3: the screening of producing urease and EC hydrolase bacterial strain lactic acid bacteria d6

[0088] Preliminary screening: Weigh 1g of rice wine fermented mash into a sterile EP tube, take 1mL of sterile saline and mix well, dilute to an appropriate multiple, take 100μL and apply it to the separation culture, and cultivate it in a constant temperature incubator at 37°C for several days until a single colony grows. Use the QPix420 screening system to screen bacteria, pick a single colony into a 48-well plate with screening medium, and culture it anaerobically at 37°C for several hours. Since urease or EC hydrolase can react with the corresponding substrate to produce ammonia, the bromocresol purple changes from purple to yellow. According to the color reaction, select the target strain for primary screening.

[0089] Re-screening: select the target strain of primary screening and inoculate it in MRS medium for 72 hours, take the bacterial liquid in a refr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com