Preparation method of surface for cell adherent growth under serum-free condition

A serum-free and cell-free technology, applied in biochemical equipment and methods, cell culture supports/coatings, microorganisms, etc., can solve problems such as reducing mass production costs and coating foaming, and improve shelf life and uniformity High, uniform monomer concentration distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

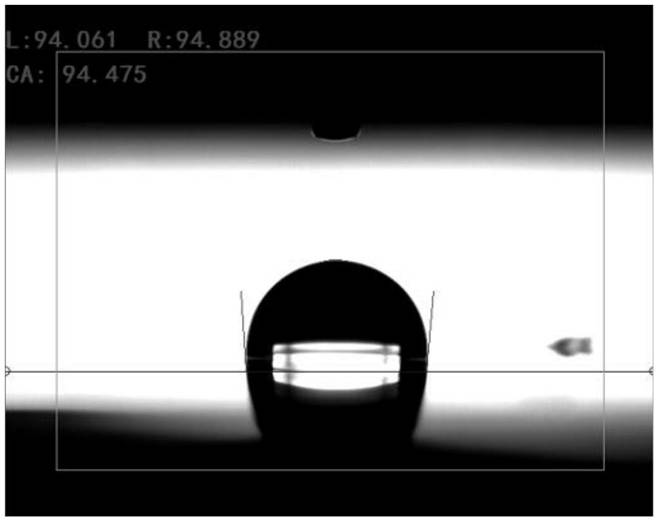

[0027] (1) Plasma cleaning treatment: After placing the culture vessel in the plasma cavity, vacuumize to a vacuum degree of 5Pa. Under the conditions of plasma power 50W, radio frequency 13.56MHz, and air flow 50sccm, the polystyrene substrate was subjected to plasma discharge treatment for 3 minutes. This step can remove the release agent and hydrocarbons on the surface of the culture vessel, roughen the surface and introduce oxygen-containing functional groups to improve the hydrophilicity of the surface.

[0028] (2) Coating the mixed solution of acrylic acid and L-proline by ultrasonic atomization process: the culture vessel treated in step (1) was taken out of the plasma chamber and placed in an ultrasonic atomization sprayer. Mix acrylic acid aqueous solution with a concentration of 30% and L-proline with a purity of 99% at a mass ratio of 2:1, and the mixed solution is uniformly coated on the substrate with a spray flow rate of 50mL / min after ultrasonic atomization. m...

Embodiment 2

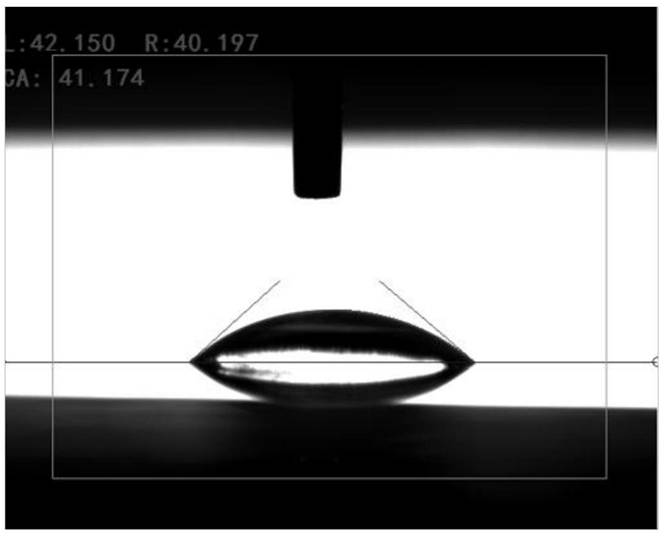

[0035](1) Plasma cleaning treatment: After placing the culture vessel in the plasma cavity, vacuumize to a vacuum degree of 15Pa. Under the conditions of plasma power 80W, radio frequency 13.56MHz, and air flow 50sccm, the polystyrene substrate was subjected to plasma discharge treatment for 6 minutes. This step can remove the release agent and hydrocarbons on the surface of the culture vessel, roughen the surface and introduce oxygen-containing functional groups to improve the hydrophilicity of the surface.

[0036] (2) Coating the mixed solution of acrylic acid and L-proline by ultrasonic atomization process: the culture vessel treated in step (1) was taken out of the plasma chamber and placed in an ultrasonic atomization sprayer. Mix acrylic acid aqueous solution with a concentration of 20% and L-proline with a purity of 99% at a mass ratio of 4:1, and the mixed solution is sprayed at a flow rate of 50mL / min and evenly coated on the substrate after ultrasonic atomization. ...

Embodiment 3

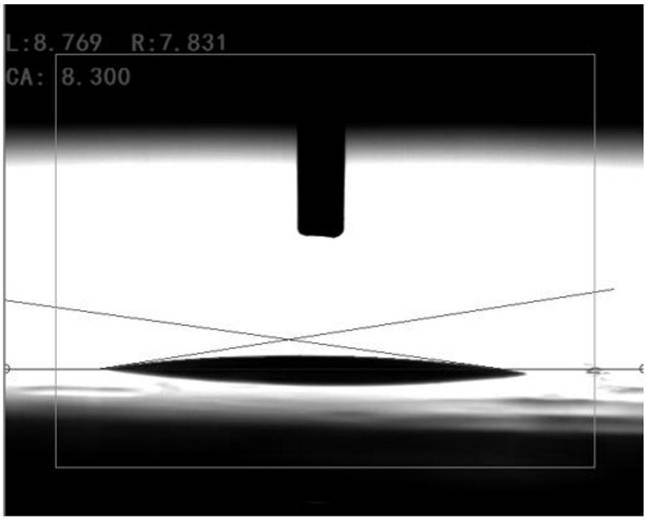

[0039] (1) Plasma cleaning treatment: After placing the culture vessel in the plasma cavity, vacuumize to a vacuum degree of 8Pa. At the beginning, under the conditions of plasma power 100W, radio frequency 13.56MHz, and air flow 10sccm, the polystyrene substrate was subjected to plasma discharge treatment for 10 minutes. This step can remove the release agent and hydrocarbons on the surface of the culture vessel, roughen the surface and introduce oxygen-containing functional groups to improve the hydrophilicity of the surface.

[0040] (2) Coating the mixed solution of acrylic acid and L-proline by ultrasonic atomization process: the culture vessel treated in step (1) was taken out of the plasma chamber and placed in an ultrasonic atomization sprayer. Mix acrylic acid aqueous solution with a concentration of 50% and L-proline with a purity of 99% at a mass ratio of 5:1. The mixed solution is sprayed at a flow rate of 30mL / min and evenly coated on the substrate after ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com