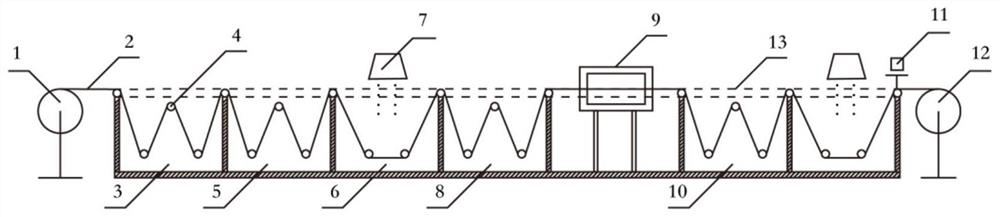

Basalt fiber continuous chemical plating device and application method

A technology of basalt fiber and electroless nickel plating, applied in liquid chemical plating, transportation, packaging, coating, etc. Hazards and other problems, to achieve the same forward speed, uniform force, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A basalt fiber continuous electroless nickel plating device and application method, comprising the steps of:

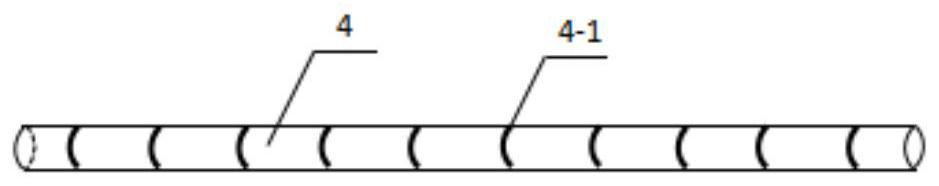

[0048] (1) 50 bundles of continuous basalt fibers (the number of bundles of filaments: 0.4k / diameter of filaments: 5μm) are pulled out from the fiber reel of the unwinding frame and passed between the grooves of the guide rollers above the front wall of the degreasing tank. The length of the guide rollers is 1200mm , 30mm in diameter, the opening diameter of the groove on the guide roller is 5mm, the groove depth is 3mm, the groove spacing is 20mm, the number of grooves is 50, and then the fiber enters the degreasing tank to degrease the fiber. There are two guide rollers at a distance of 100mm from the bottom of the degreasing tank, the distance between the two guide rollers is 600mm, and the time for the fiber bundle to pass through the degreasing tank is 10 minutes;

[0049] (2) The fiber bundles that have undergone degreasing treatment enter the roughening ...

Embodiment 2

[0058] A basalt fiber continuous electroless nickel plating device and application method, comprising the steps of:

[0059] (1) 10 bundles of continuous basalt fibers (the number of bundles of filaments is 0.2k / diameter of filaments is 7μm) are pulled out from the fiber reel of the unwinding frame and penetrated between the grooves of the guide rollers above the front wall of the degreasing tank, and the length of the guide rollers is 1200mm , the diameter is 70mm, the opening diameter of the groove on the guide roller is 10mm, the groove depth is 7mm, the groove spacing is 100mm, and the number of grooves is 10. After that, the fiber enters the degreasing tank for degreasing treatment. There are two guide rollers at a distance of 100mm from the bottom of the degreasing tank, the distance between the two guide rollers is 600mm, and the time for the fiber bundle to pass through the degreasing tank is 10 minutes;

[0060] (2) The fiber bundles that have undergone degreasing tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com