Preparation method of low-refractive index nanofiber membrane for alcohol detection

A technology of nanofiber membrane and low refractive index, applied in fiber treatment, fiber chemical characteristics, cellulose/protein conjugated artificial filament, etc., can solve the problems of chemical sensor effectiveness limitation, functional damage, and inability to meet universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

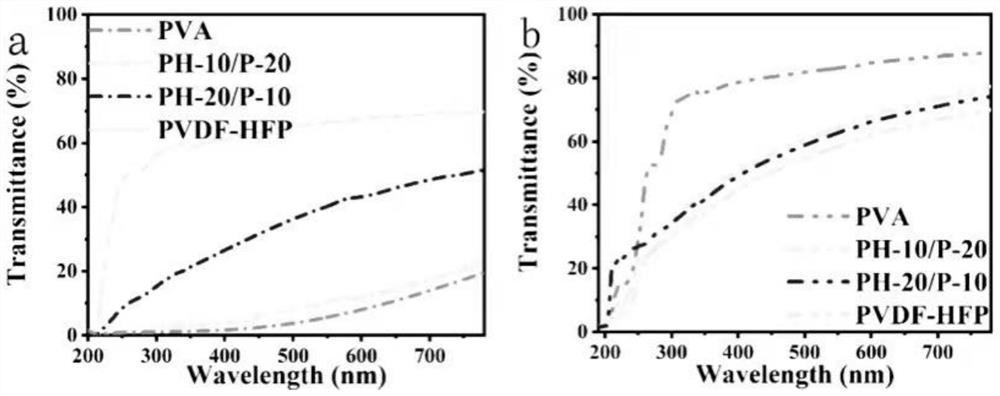

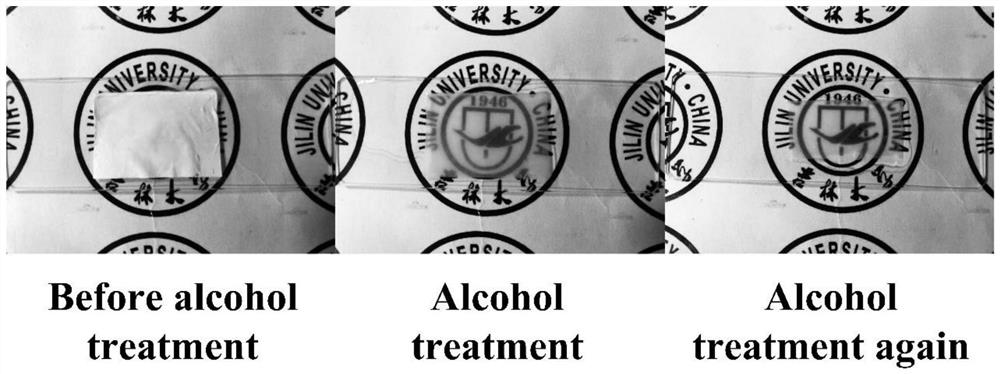

[0032] This embodiment provides a kind of preparation method of the low refractive index nanofiber membrane that is used for alcohol detection, and it comprises the following steps:

[0033] S1. Weigh a certain amount of polyvinyl alcohol and distilled water, put the polyvinyl alcohol and distilled water into the reagent bottle A according to a certain ratio, and then weigh a certain amount of perfluorodecyltriethoxysilane and dissolve it in the above PVA solution In the process, a fluorine-rich PVA solution with a mass concentration of 12% was obtained, and stirred and mixed on a magnetic stirrer for 2 hours to obtain a clear and uniform first spinning precursor solution.

[0034] S2. Weigh a certain amount of N,N-dimethylformamide and acetone, put N,N-dimethylformamide and acetone into the reagent bottle B according to the volume ratio of 7:3 to obtain a clear and uniform total Solvent, then weigh a certain amount of polyvinylidene fluoride-hexafluoroethylene and add it to t...

Embodiment 2

[0038] This embodiment provides a kind of preparation method of the low refractive index nanofiber membrane that is used for alcohol detection, and it comprises the following steps:

[0039] S1. Weigh a certain amount of polyvinyl alcohol and distilled water, put the polyvinyl alcohol and distilled water into the reagent bottle A according to a certain ratio, and then weigh a certain amount of perfluorodecyltriethoxysilane and dissolve it in the above PVA solution In the process, a fluorine-rich PVA solution with a mass concentration of 12% was obtained, and stirred and mixed on a magnetic stirrer for 2 hours to obtain a clear and uniform first spinning precursor solution.

[0040] S2. Weigh a certain amount of N,N-dimethylformamide and acetone, put N,N-dimethylformamide and acetone into the reagent bottle B according to the volume ratio of 7:3 to obtain a clear and uniform total Solvent, then weigh a certain amount of polyvinylidene fluoride-hexafluoroethylene and add it to t...

Embodiment 3

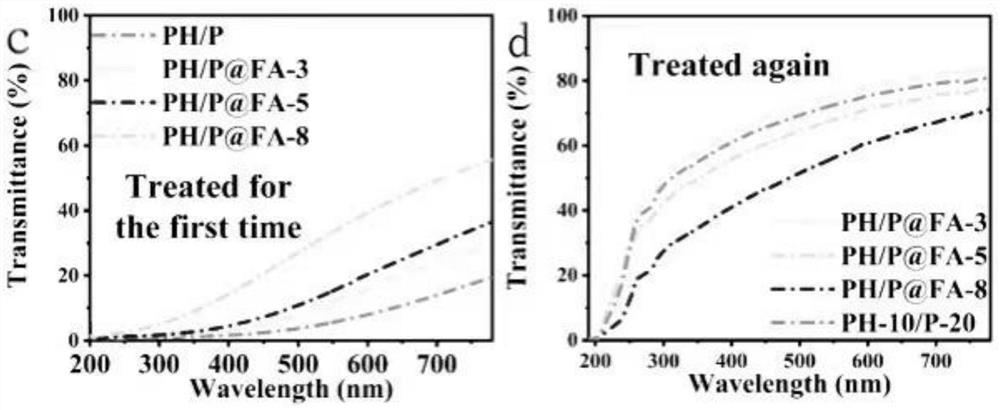

[0044] This embodiment provides a kind of preparation method of the low refractive index nanofiber membrane that is used for alcohol detection, and it comprises the following steps:

[0045] S1. Weigh a certain amount of polyvinyl alcohol and distilled water, put the polyvinyl alcohol and distilled water into the reagent bottle A according to a certain ratio, and then weigh a certain mass of perfluorodecyltriethoxysilane with a concentration of 3%. Dissolve in the above PVA solution to obtain a fluorine-rich PVA solution with a mass concentration of 12%. Stir and mix on a magnetic stirrer for 2 hours to obtain a clear and uniform first spinning precursor solution.

[0046] S2. Weigh a certain amount of N,N-dimethylformamide and acetone, put N,N-dimethylformamide and acetone into the reagent bottle B according to the volume ratio of 7:3 to obtain a clear and uniform total Solvent, then weigh a certain amount of polyvinylidene fluoride-hexafluoroethylene (PVDF-HFP) and add it to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com