N-type GaAs ohmic contact electrode material and preparation method thereof

An ohmic contact electrode, n-type technology, applied in metal material coating process, circuits, electrical components, etc., can solve the problems of high equipment cost, troublesome cleaning, high vacuum degree, etc., to achieve low equipment cost and no waste of electrode materials. , The effect of electrode composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

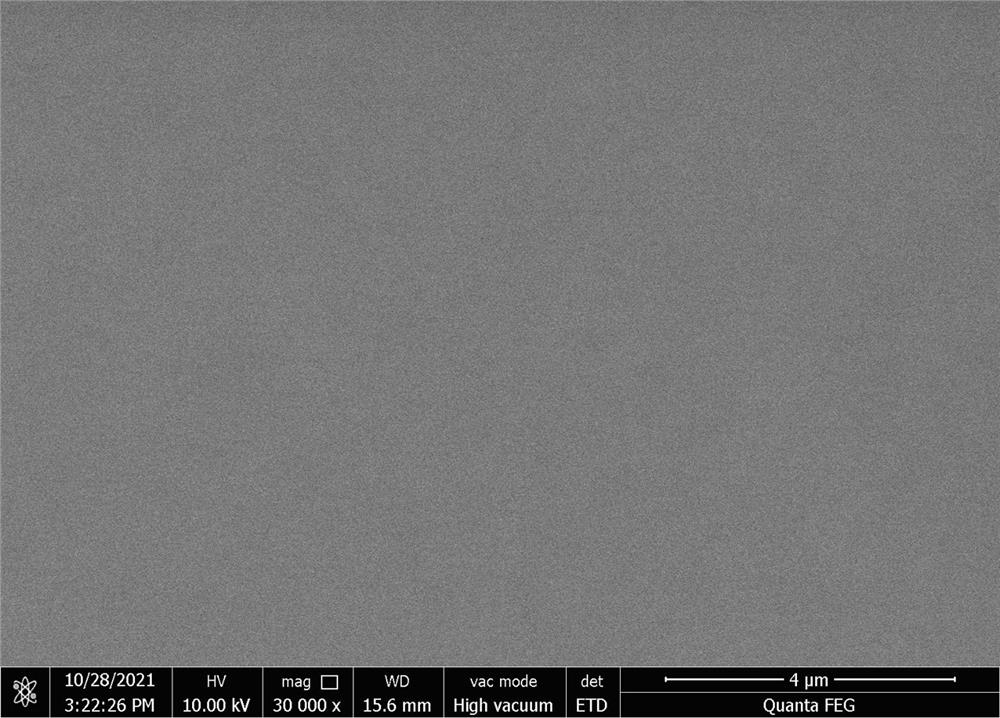

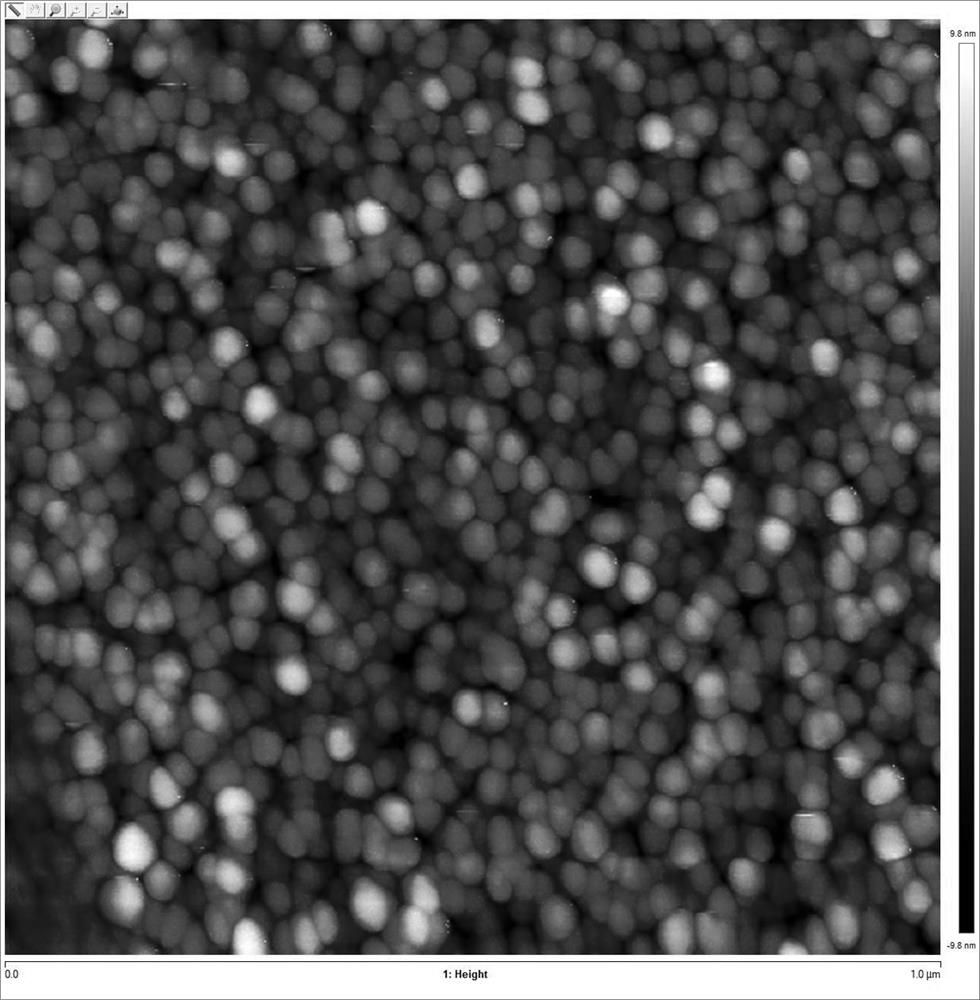

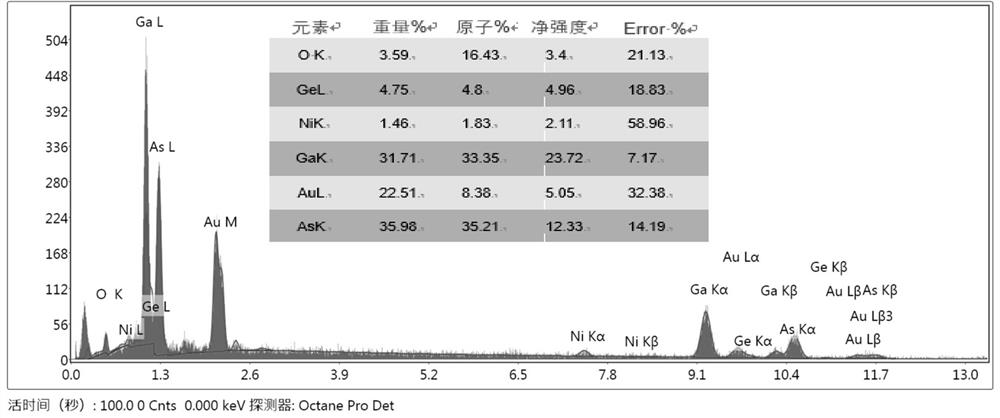

[0024] Two electrode regions were set on the n-type GaAs substrate by mask method, and AuGeNi alloy was firstly sputtered by ion sputtering method: the distance between the AuGeNi alloy target and the substrate was 5 cm. Turn on the mechanical pump, vacuum the chamber to 2Pa, pour in air and adjust the pressure in the chamber to 6 Pa to start sputtering. During the sputtering process, the current is kept at 5 mA by fine-tuning the pressure, and the thickness of the AuGeNi alloy layer needs to reach 50~70 nm . Then sputter gold Au: the distance between the gold Au target and the substrate is 7 cm, turn on the mechanical pump, evacuate the chamber to 2 Pa, pour air into the chamber to adjust the pressure in the chamber to 6 Pa, and start sputtering. The sputtering process passes Fine-tune the air pressure to keep the current at 5 mA, and the thickness of the Au layer must reach 100-120 nm. After the electrode thickness reaches the requirement, move the substrate to the tube ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com