Leadless packaging structure and method of high-temperature-resistant sensor

A technology of packaging structure and high temperature resistance, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., to reduce the possibility of thermal stress mismatch, eliminate response time lag, and low process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

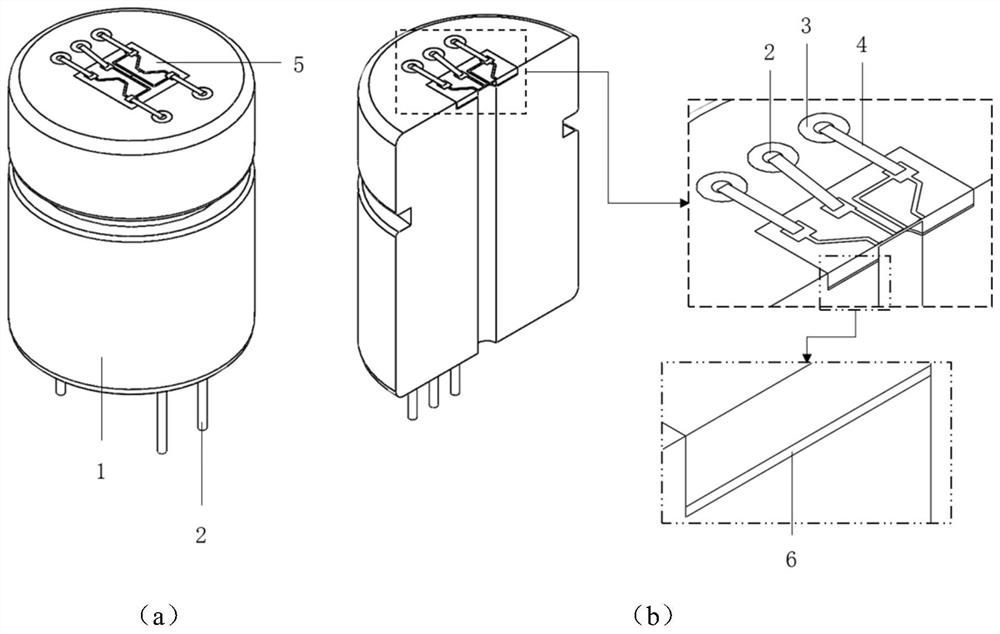

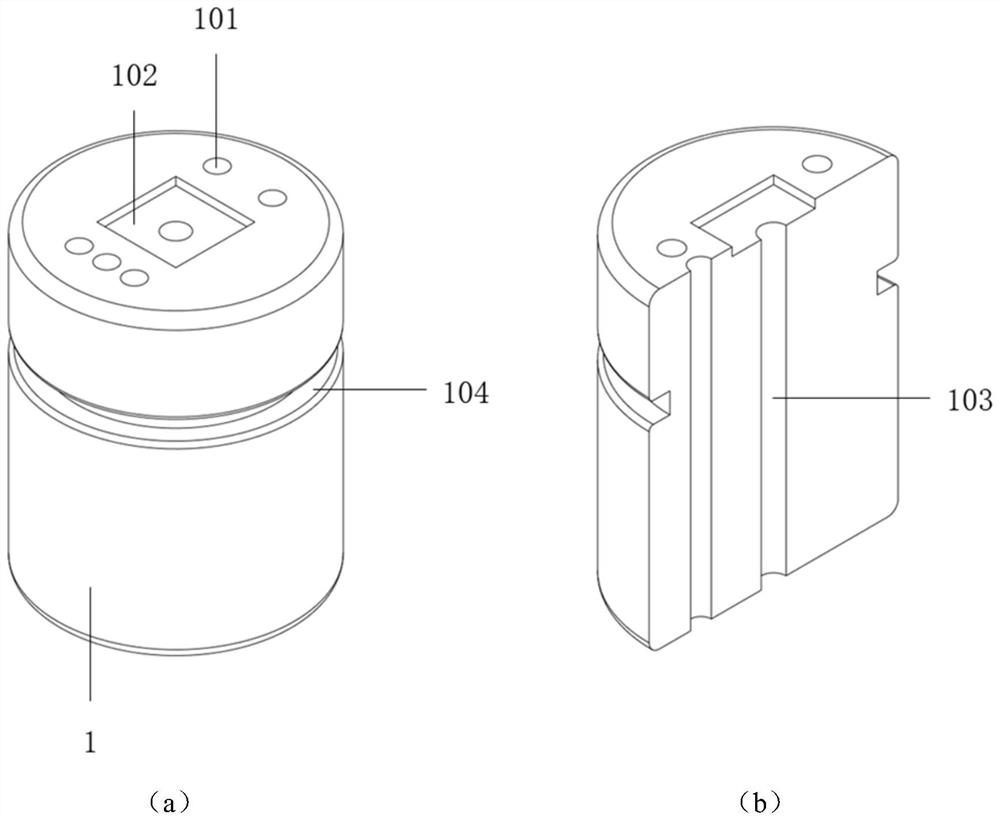

[0049] Such as figure 1 As shown, the overall packaging structure of the high temperature resistant sensor includes a sensor housing 1 , metal pins 2 and a sensor chip 5 . A part of the metal pin 2 is fixed inside the sensor housing 1 through the conductive sealing block 3 formed by the cured conductive glass paste, and the sensor chip 5 is fixed in the sealing layer formed by the cured high temperature resistant adhesive. 6 is fixed on the upper end surface of the sensor housing 1 in a fitting manner; wherein, the sensor chip 5 faces upward, and the upper end of the metal pin 2, the cured conductive glass paste, and the front surface of the sensor chip 5 are all in contact with the sensor housing. 1 is flush with the upper end surface, the lower end of the metal pin 2 protrudes out of the lower end surface of the sensor housing 1 , and the back of the sensor chip 5 is opposite to the channel or cavity structure inside the sensor housing 1 . On the junction of the upper end s...

Embodiment 2

[0088] The above embodiment 1 is aimed at the relatively friendly working environment of the sensor chip, for example, the situation that the chip is not in direct contact with water vapor, dust or corrosive substances. If the sensor chip works in an environment containing water vapor, dust or corrosive substances, it is necessary to consider using the packaging structure to protect the circuit structure on the front of the sensor chip, so Embodiment 2 is proposed.

[0089] Such as Figure 5 As shown in a, the main difference between the overall packaging structure of the high temperature resistant sensor of this embodiment and that of Embodiment 1 is that the sensor chip 5 is placed upside down in the chip packaging groove 102, that is, the back of the sensor chip 5 faces upward, and the circular through hole 101 The layout positions on the end surface of the sensor housing 1 are all located inside the chip packaging groove 102, that is, the upper end of the circular through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com