Road water stabilizing layer material and preparation method thereof

A water-stabilizing layer and road technology, applied in the field of road water-stabilizing layer materials and its preparation, can solve problems such as the difficulty of uniform dispersion, and achieve an obvious effect of promoting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

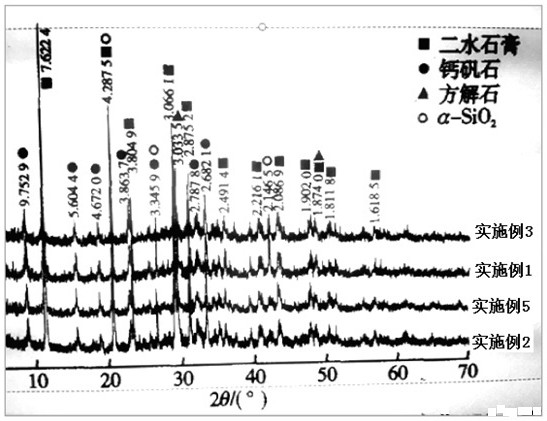

Embodiment 1

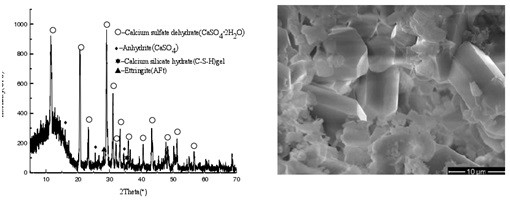

[0031] Example 1 Weigh 85 kg of phosphogypsum (containing 16% of free water), add 2.0 kg of quicklime (70% of calcium oxide), mix well and let stand for 24 hours. Add 10 kg of 42.5 Portland cement and activator (activator ratio, weight ratio: 55% of large particle size silica sol (90nm), 8% of silicon nitride, 3.5% of sulfonated melamine water reducer, K-30 dispersion 3% agent, 30.5% water) 3 kg was released after stirring for 10 minutes with a mixing mixer. Then prepare samples and maintain according to the regulations.

[0032] The 3-day unconfined compressive strength is 2.3MPa, the 7-day unconfined compressive strength is 3.5MPa, the 14-day 8.6MPa, and the 28-day 10.2MPa.

Embodiment 2

[0033] Example 2 Weigh 85 kg of phosphogypsum (free water 16%), add 2.0 kg of quicklime, mix evenly and let stand for 24 hours. Add 10 kg of 42.5 Portland cement and activator (ratio of activator, weight ratio: nano-silica sol E31 (D50 13nm, solid content 50% market purchase) 60%, silicon nitride 8%, sulfonated melamine water reducer 3.5%, K-30 dispersant 3%, water 25.5%) 3 kg with a mixing mixer for 10 minutes before release. Then prepare samples and maintain according to the regulations.

[0034] The 3-day unconfined compressive strength was 1.4MPa, the 7-day unconfined compressive strength was 2.6MPa, the 14-day unconfined compressive strength was 5.8MPa, and the 28-day unconfined compressive strength was 7.1MPa.

Embodiment 3

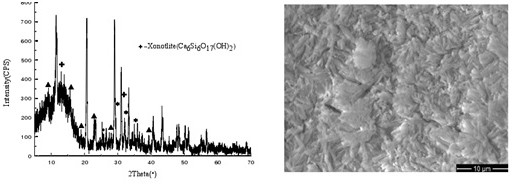

[0035]Example 3 Weigh 85 kg of phosphogypsum (free water 16%), add 2.0 kg of quicklime, mix evenly and let stand for 24 hours. Add 10 kg of 42.5 Portland cement and 3 kg of activator (proportion of activator: large particle size silica sol (90nm) 55%, silicon nitride 8%, sulfonated melamine water reducer 3.5%, water 33.5%). Stir with a mixing mixer for 10 minutes and release. Then prepare samples and maintain according to the regulations.

[0036] The 3-day unconfined compressive strength is 1.2MPa, the 7-day unconfined compressive strength is 2.1MPa, the 14-day 4.9MPa, and the 28-day 6.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com