Method for preparing ethane through methane anaerobic coupling based on monatomic catalyst

A catalyst and atom technology, which is applied in the field of oxygen-free coupling of methane to prepare ethane based on single-atom catalysts, can solve the problems of rising production costs, high temperature, unsatisfactory selectivity of multi-carbon products, etc., and achieves high selectivity, high The effect of ethane selectivity and ease of subsequent separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Preparation of catalyst

[0044] The preparation of the single-atom catalyst used in the present invention (palladium single-atom-supported titanium dioxide catalyst) is as follows:

[0045] Step 1) Preparation of TiO2 Nanosheets

[0046]Add 5-10 mL of tetrabutyl titanate and 0.8-1.6 mL of hydrofluoric acid into the lining of the polytetrafluoroethylene hydrothermal kettle, stir at room temperature for 30 minutes, and then transfer it to the high-pressure hydrothermal kettle, and then put the hydrothermal kettle into the oven React at 180°C for 24h. After the hydrothermal kettle was cooled to room temperature, the obtained white solid was repeatedly washed with deionized water until the pH value was neutral and dried to obtain anatase-phase titanium dioxide nanosheets

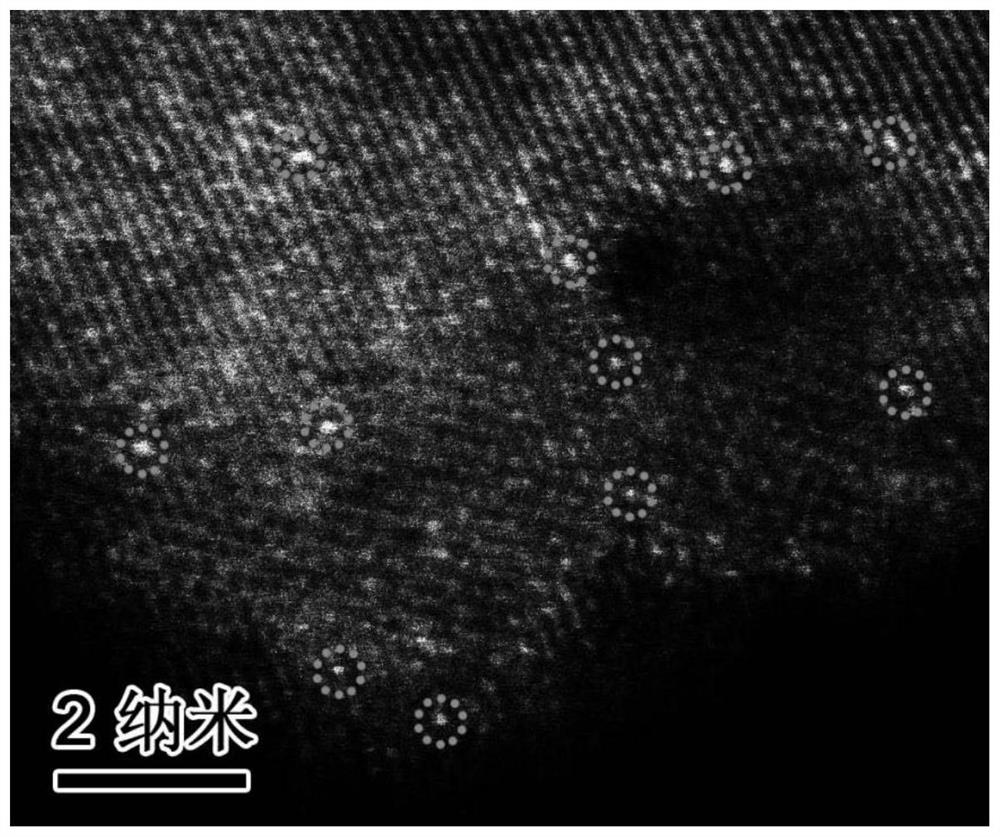

[0047] Step 2) Preparation of Palladium Single Atom Supported Titanium Dioxide Catalyst

[0048] Add 20-200 mg of titanium dioxide nanosheets into a closed glass bottle, and disperse uniformly with 5-...

Embodiment 1

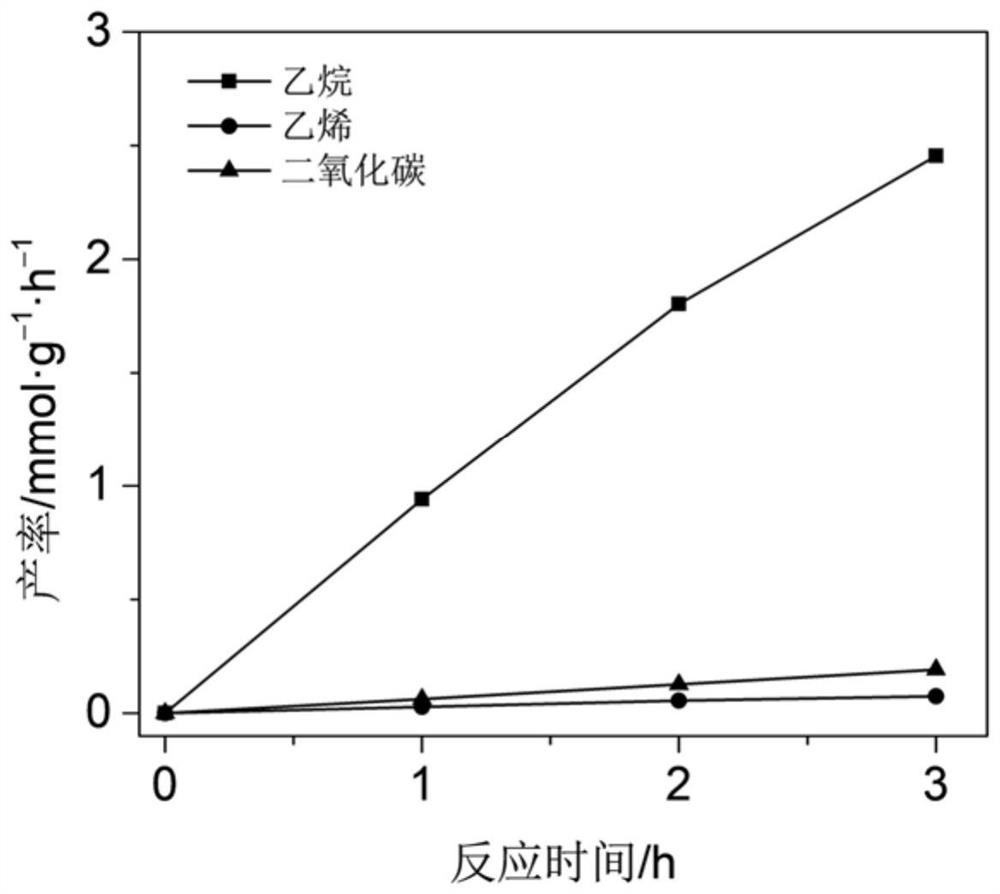

[0056] Add 20 mg of palladium monoatomic-supported titanium dioxide complex as a catalyst to the quartz reactor, and then pass high-purity (purity greater than 99.9%) methane gas into a methane cylinder through a pressure reducing valve, and then seal the reactor (the pressure in the reactor is 0.1 MPa). . At room temperature (about 25°C), using a xenon lamp as a light source at 600mW / cm 2 The reaction was carried out under the light intensity of 3 h. After the reaction, gas samples were taken to determine the product distribution by gas chromatography. Gas chromatography GC detection conditions are: Agilent 7890BGC, Ar carrier gas, FID detector, capillary column, column temperature 60°C.

[0057] The product was determined to be predominantly ethane by gas chromatography and its selectivity was 93%.

[0058] figure 2 The real-time changing values during the photocatalytic methane-free coupling process of palladium single-atom supported titania catalyst are schematicall...

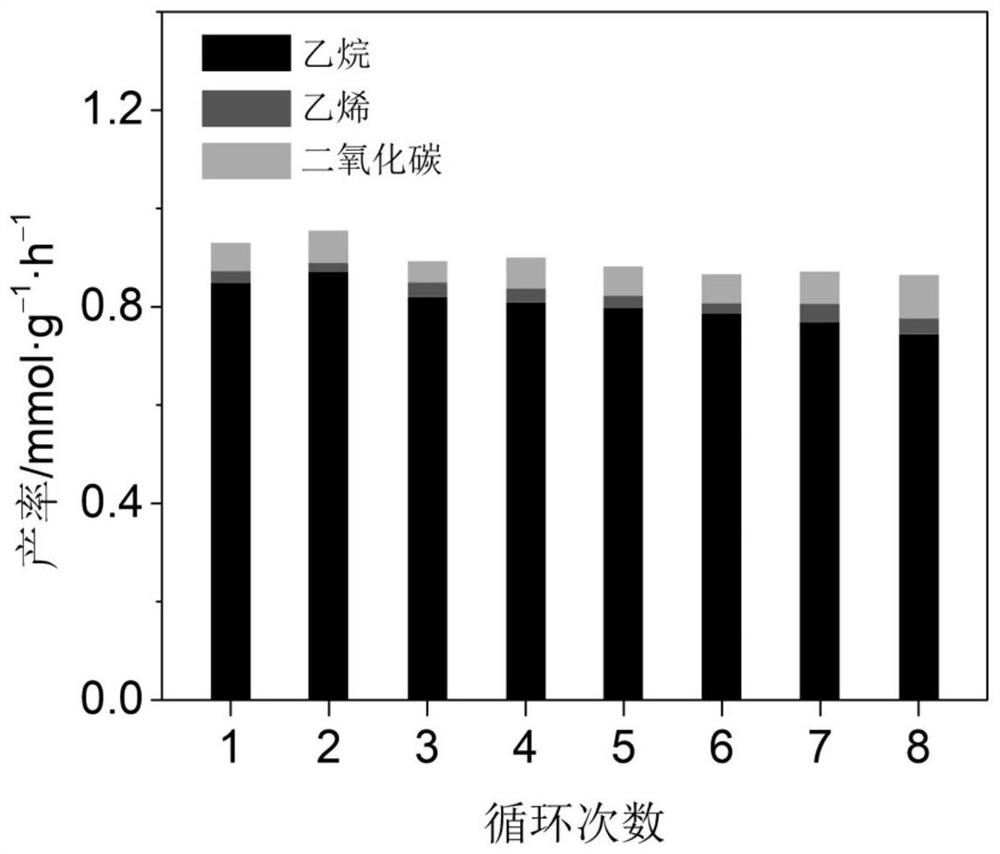

Embodiment 2

[0061] The specific reaction process and detection method are the same as in Example 1, except that the titanium dioxide nanorods are used as carriers to prepare a palladium single-atom supported titanium dioxide composite. After testing, the yield of ethane was 0.78 mmol / g / h, and the selectivity was 89%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap