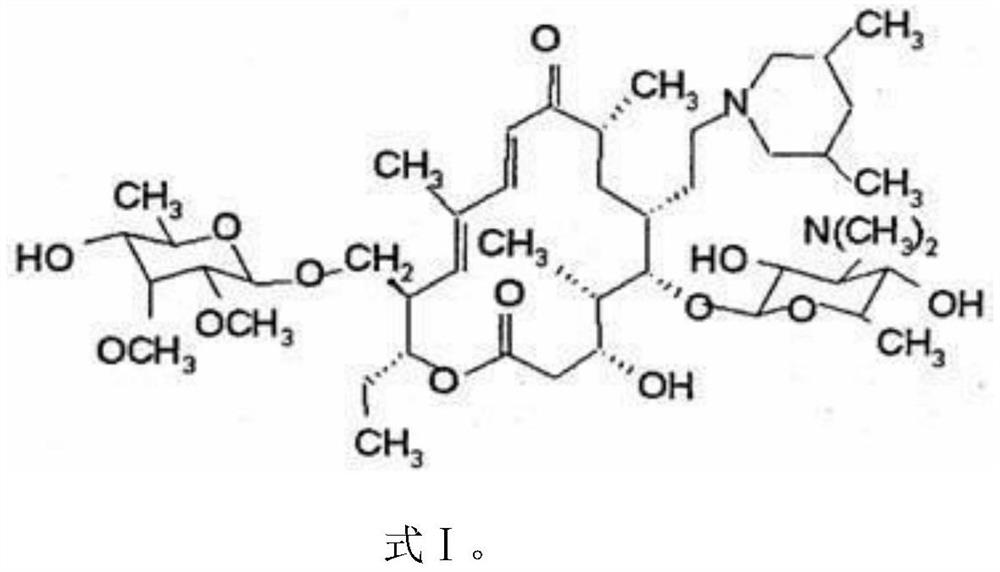

Production method for improving quality of tilmicosin phosphate

A technology for tilmicosin phosphate and a production method, which is applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of high residual water content of butyl acetate, long operation time, influence on amination reaction and the like , to achieve the effect of shortening the time for butyl acetate to extract static water, reducing production man-hours and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A production method improving the quality of tilmicosin phosphate, the method is as follows:

[0029] 1) Use butyl acetate as the extractant to perform countercurrent extraction on the tylosin tartrate concentrated solution, collect the extract, the volume ratio of the tylosin tartrate concentrated solution to butyl acetate is 10:4, and the extraction temperature is 45°C. pH control at 7.0;

[0030] 2) After adding butyl acetate for extraction, stand still for 35 min, discard the water phase, and obtain 5 m of butyl acetate extract 3 ;

[0031] 3) adding anhydrous sodium sulfate to the extract, stirring for 50 minutes, then filtering to remove anhydrous sodium sulfate, and then performing amination synthesis; the amount of anhydrous sodium sulfate added is 8.0% of the quality of the extract;

[0032] 4) Add 3,5-dimethylpiperidine, formic acid and ethyl acetate to the system for amination reaction, the molar ratio of tylosin to 3,5-dimethylpiperidine is 1:1; The molar...

Embodiment 2

[0035] A production method improving the quality of tilmicosin phosphate, the method is as follows:

[0036] 1) Use butyl acetate as the extractant to perform countercurrent extraction on the tylosin tartrate concentrated solution, collect the extract, the volume ratio of the tylosin tartrate concentrated solution to butyl acetate is 10:4.5, and the extraction temperature is 45°C. pH control at 7.0;

[0037] 2) After adding butyl acetate for extraction, stand still for 30 min, discard the water phase, and obtain 5 m of butyl acetate extract 3 ;

[0038] 3) adding anhydrous sodium sulfate to the extract, stirring for 40 minutes, then filtering to remove anhydrous sodium sulfate, and then performing amination synthesis; the amount of anhydrous sodium sulfate added is 10.0% of the quality of the extract;

[0039] 4) Add 3,5-dimethylpiperidine, formic acid and ethyl acetate to the system for amination reaction, the molar ratio of tylosin to 3,5-dimethylpiperidine is 1:1.5; Tylos...

Embodiment 3

[0042] A production method improving the quality of tilmicosin phosphate, the method is as follows:

[0043] 1) Use butyl acetate as the extractant to perform countercurrent extraction on the tylosin tartrate concentrated solution, collect the extract, the volume ratio of the tylosin tartrate concentrated solution to butyl acetate is 11:4.5, and the extraction temperature is 45°C. pH control at 7.0;

[0044] 2) After adding butyl acetate for extraction, stand still for 25 min, discard the water phase, and obtain 5 m of butyl acetate extract 3 ;

[0045] 3) adding anhydrous sodium sulfate to the extract, stirring for 45 minutes, then filtering to remove anhydrous sodium sulfate, and then performing amination synthesis; the amount of anhydrous sodium sulfate added is 7.0% of the mass of the extract;

[0046] 4) Add 3,5-dimethylpiperidine, formic acid and ethyl acetate to the system for amination reaction, the molar ratio of tylosin to 3,5-dimethylpiperidine is 1:1.5; Tylosin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com