High-efficiency light electromagnetic absorbing material with closed-pore structure and preparation method of high-efficiency light electromagnetic absorbing material

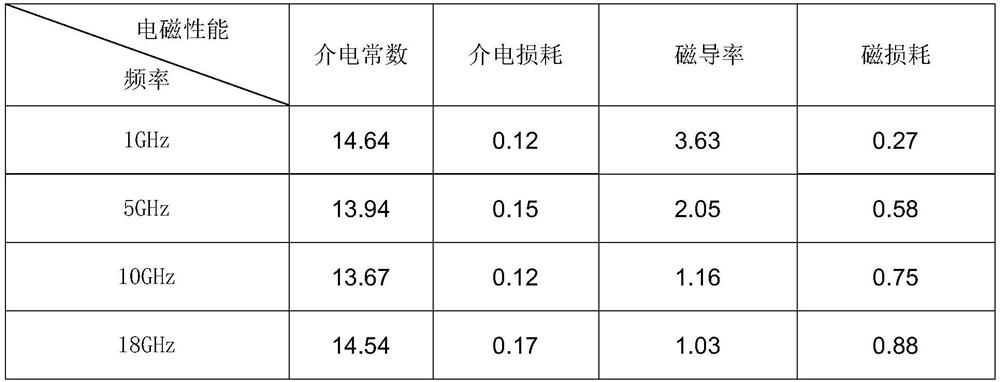

A closed-cell structure and absorbing material technology, which is applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problems of material thermal conductivity limitation, absorption efficiency priority, large size of absorbing material, etc., to improve electromagnetic absorption performance and make up holes The effect of internal air pressure change and increased dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A method for preparing a high-efficiency light-weight electromagnetic absorbing material with a closed-cell structure, comprising the following steps:

[0057] (1) Mix thermosetting resin, absorbent, diluent, and thermally conductive filler evenly, heat to 30-60°C and stir for 5-40 minutes; cool to room temperature, continue to add curing accelerator, chemical foaming agent and foam stabilizer, and Choose whether to add curing agent according to the needs, and get the slurry after stirring for 5-30 minutes;

[0058] (2) adding the stirred slurry into a sealed container, and then introducing supercritical carbon dioxide gas into it to form a porous slurry;

[0059] (3) Heat the closed mold to 80-100°C, inject the porous slurry into the mold, withdraw the mold to make the slurry fully foam and fully fill the mold cavity, and the degree of mold withdrawal is to expand the mold cavity by 1.3 -1.8 times;

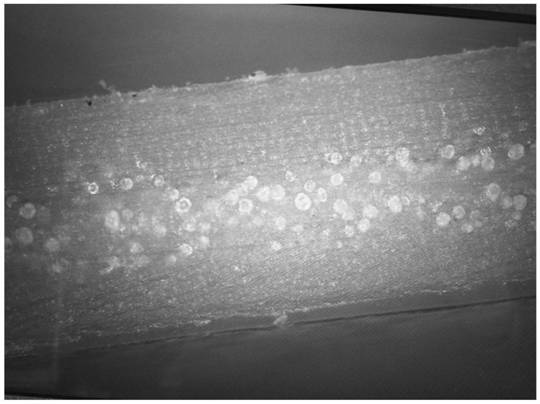

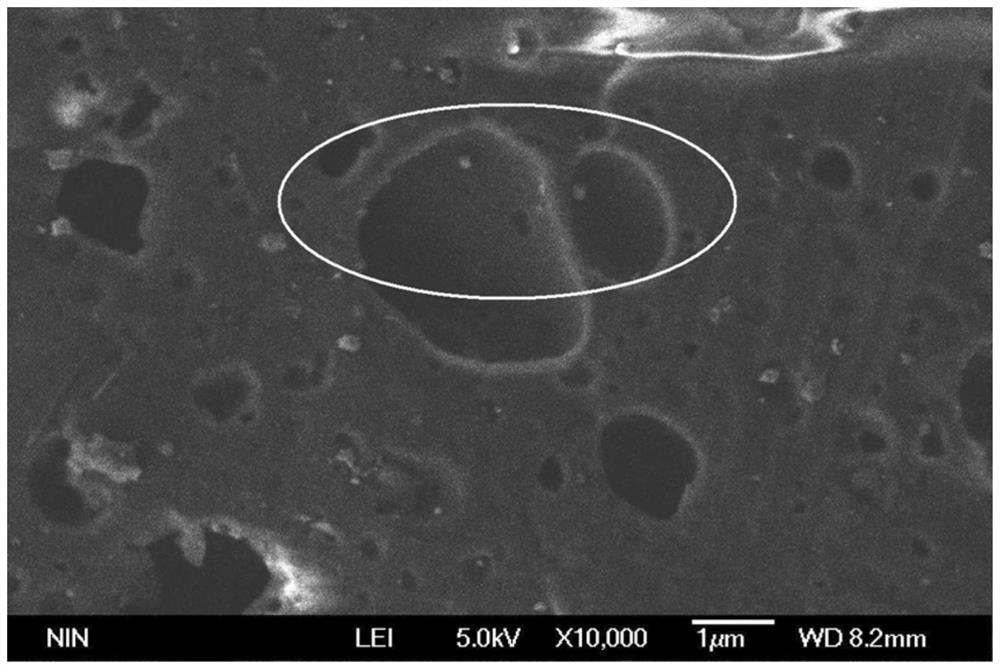

[0060] (4) Demoulding after heat preservation for a set time to prepa...

Embodiment 1

[0063] (1) Mix 58 parts of carbonyl iron powder absorbent and 25 parts of graphite powder by ball milling, then add 15 parts of epoxy resin and 3 parts of ethylene glycol bisglycidyl ether, heat to 50°C and stir for 25 minutes to obtain no agglomeration Shaped resin slurry; cool to room temperature and continue to add 6 parts of diaminodiphenylmethane, 3 parts of diethanolamine, 5 parts of calcium carbonate and 0.8 part of polyoxyethylene sorbitan laurate, after stirring for 15min, the viscosity is obtained at 19000- Slurry within the range of 21000mps (rotational viscometer);

[0064] (2) Add the stirred slurry into a sealed pressure vessel, then feed supercritical carbon dioxide gas into it to form a porous slurry;

[0065] (3) Heating the closed mold to 100°C, injecting the porous slurry into the mold, withdrawing the mold to make the slurry fully foam and fully fill the mold cavity, wherein the degree of mold withdrawal is such that the mold cavity is enlarged by 1.5 times...

Embodiment 2

[0070] (1) Mix 110 parts of carbonyl iron powder absorbent and 20 parts of graphite powder by ball milling, then add to 24 parts of epoxy resin and 5 parts of ethylene glycol bisglycidyl ether, heat to 60°C and stir for 25 minutes to obtain no agglomeration Shaped resin slurry; cool to room temperature and continue to add 9 parts of diaminodiphenylmethane, 3 parts of diethanolamine, 8 parts of calcium carbonate and 1.5 parts of polyoxyethylene sorbitan laurate, after stirring for 20min, the viscosity is obtained at 20000- Slurry within the range of 23000mps (rotational viscometer);

[0071] (2) Add the stirred slurry into a sealed pressure vessel, then feed supercritical carbon dioxide gas into it to form a porous slurry;

[0072] (3) Heating the closed mold to 100°C, injecting the porous slurry into the mold, withdrawing the mold to make the slurry fully foam and fully fill the mold cavity, wherein the degree of mold withdrawal is such that the mold cavity is enlarged by 1.6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com