A kind of modified phenolic foam for wall insulation and preparation method thereof

A phenolic foam and modification technology, which is applied in the field of modified phenolic foam for wall insulation and its preparation, can solve the problems of insignificant reduction in water absorption, high thermal conductivity, low mechanical strength, etc., and achieve a wide range of operating temperature and density The effect of wide range and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

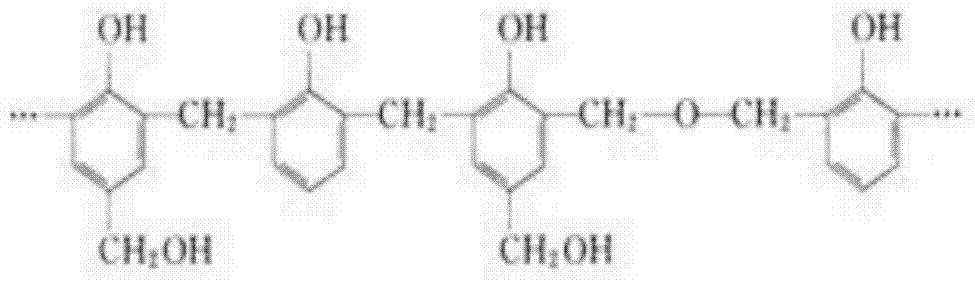

Method used

Image

Examples

Embodiment

[0051] Embodiment, preparation modified phenolic foam

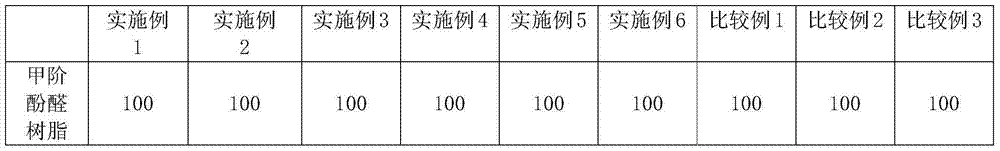

[0052] The raw material formula and the preparation process parameter of the modified phenolic foam of embodiment 1-6 and comparative example 1-3 are as shown in table 1:

[0053] Table 1 The raw material formula and preparation process parameters of the modified phenolic foam of Examples 1-6 and Comparative Examples (unit: parts by weight, which can be kg)

[0054]

[0055]

[0056] The soluble thermosetting phenolic resin used in the examples is a resole phenolic resin produced by Langfang Yiqun Energy Saving Materials Co., Ltd. (viscosity range is 150-2000 mPa·S). Other raw materials are also commercially available.

[0057] Prepare phenolic foam according to the formula and process parameters shown in Table 1, add the inorganic modifier to the phenolic resin under stirring conditions, then add coupling agent, organic modifier, foaming agent, curing agent, stir evenly, pour into Sheet continuous production line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com