Gradient foaming method for preparation of phenolic foam

A phenolic foam and gradient technology, which is applied in the field of phenolic foam preparation, can solve the problems of incomplete cell walls, low strength, easy powder and slag removal, etc., and achieves the effects of uniform density distribution, good closed-cell structure, and no cracking and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

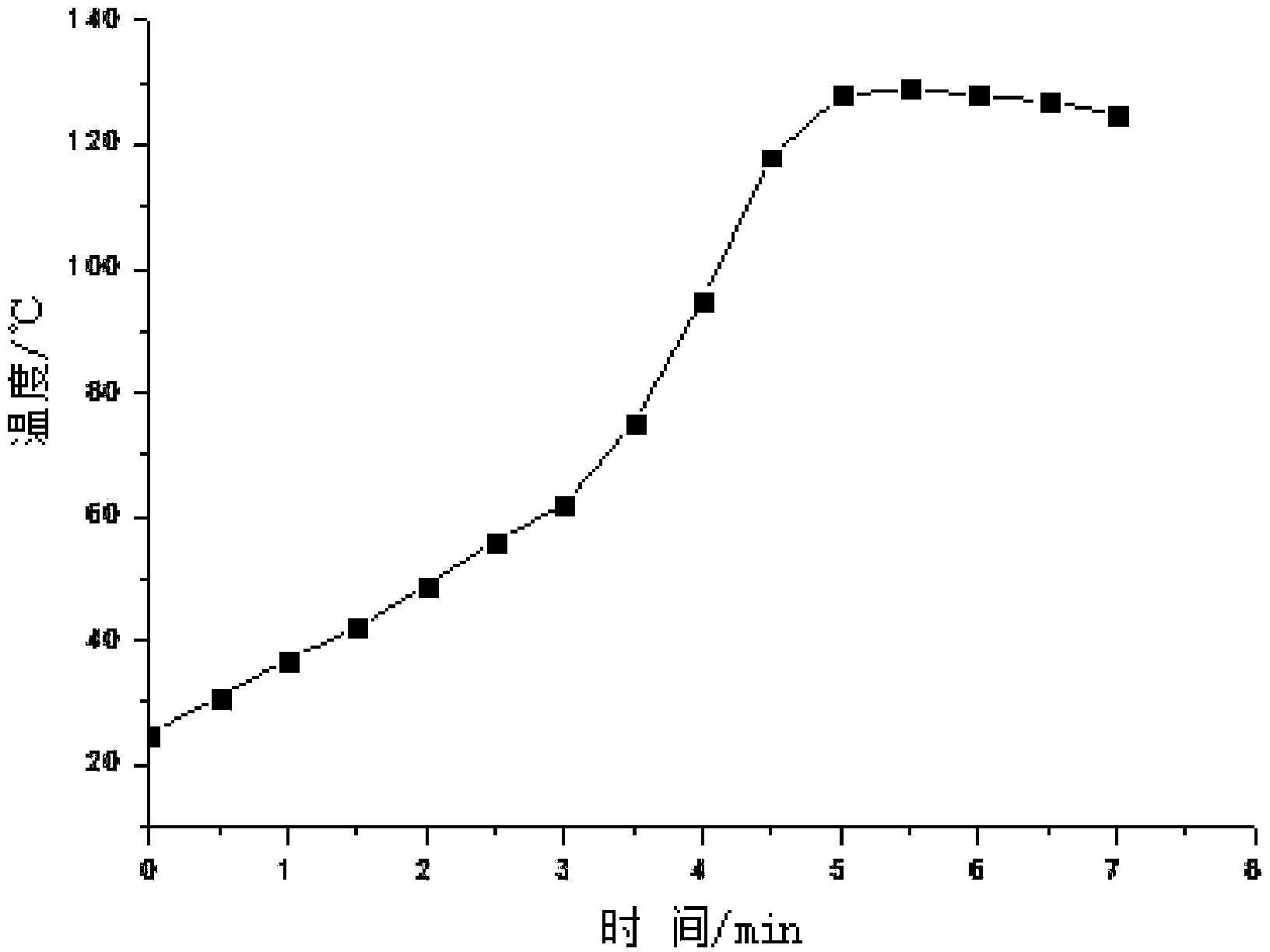

Image

Examples

Embodiment 1

[0025] A gradient foaming method prepared by phenolic foam, comprising the following steps:

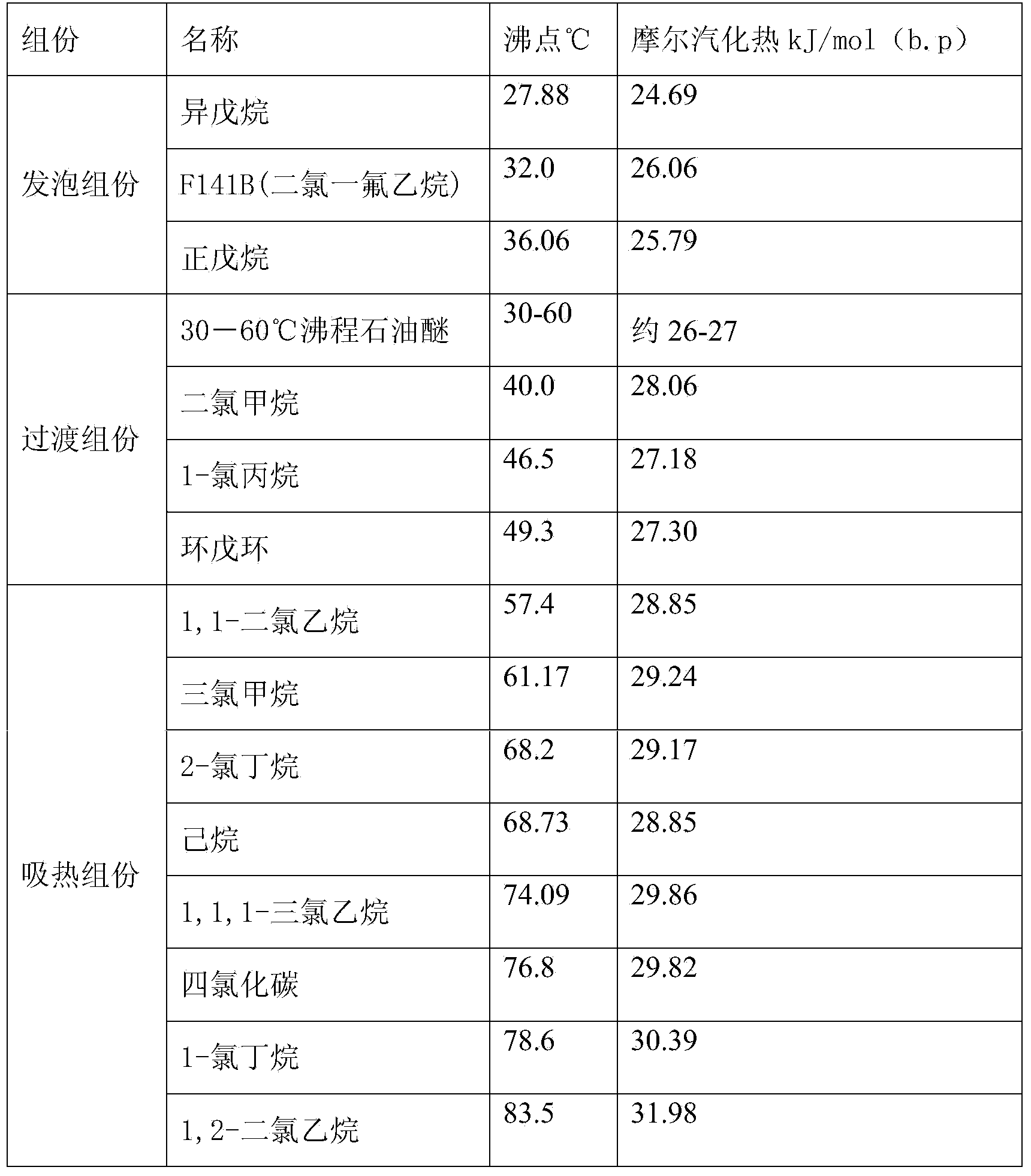

[0026] (1) Preparation of gradient foaming agent: Take 4g of n-pentane, 2.5g of petroleum ether with a boiling range of 30-60°C, and 3.5g of 2-chlorobutane, mix well and store at 15°C.

[0027] (2) Synthesis of resole phenolic resin: 564g of phenol and 324g of paraformaldehyde were added to the reaction flask, the temperature was raised to 65°C, 12g of aqueous sodium hydroxide solution with a mass fraction of 20% was added, and the reaction was carried out at 65°C for 3h. Raise the temperature to 85°C and react for 2.5h, then cool to obtain the resole phenolic resin.

[0028] (3) Preparation of phenolic foam: Add 90g of the above-mentioned resole phenolic resin, 4.5g of Tween-80, and 5.4g of the above-mentioned gradient foaming agent into the reactor and stir rapidly for 10min, then add 3g of benzenesulfonic acid and 3g of p-toluene The mixed curing agent of sulfonic acid (80% concen...

Embodiment 2

[0030] A gradient foaming method prepared by phenolic foam, comprising the following steps:

[0031] (1) Preparation of gradient foaming agent: Take 4g of isopentane, 1.5g of dichloromethane, 2g of cyclopentane, and 2.5g of hexane, mix well and store at 15°C.

[0032] (2) Synthesis of resole phenolic resin: 564g of phenol and 324g of paraformaldehyde were added to the reaction flask, the temperature was raised to 65°C, 12g of aqueous sodium hydroxide solution with a mass fraction of 20% was added, and the reaction was carried out at 65°C for 3h. Raise the temperature to 85°C and react for 2.5h, then cool to obtain the resole phenolic resin.

[0033] (3) Preparation of phenolic foam: Add 90g of the above-mentioned resole phenolic resin, 4.5g of Tween-80, and 5.4g of the above-mentioned gradient foaming agent into the reactor and stir rapidly for 10min, then add 3g of benzenesulfonic acid and 3g of p-toluene The mixed curing agent of sulfonic acid (80% concentration), after sti...

Embodiment 3

[0035] A gradient foaming method prepared by phenolic foam, comprising the following steps:

[0036] (1) Preparation of gradient foaming agent: Take 4g of isopentane, 3g of petroleum ether with a boiling range of 30-60°C, and 3g of 1-chlorobutane, mix well and store at 15°C.

[0037] (2) Synthesis of resole phenolic resin: 564g of phenol and 324g of paraformaldehyde were added to the reaction flask, the temperature was raised to 65°C, 12g of aqueous sodium hydroxide solution with a mass fraction of 20% was added, and the reaction was carried out at 65°C for 3h. Raise the temperature to 85°C and react for 2.5h, then cool to obtain the resole phenolic resin.

[0038] (3) Preparation of phenolic foam: 90g of the above-mentioned resole phenolic resin, 4.5g of castor oil polyoxyethylene ether (EL-20), and 5.4g of the above-mentioned gradient foaming agent were added to the reactor and stirred rapidly for 10min, and then added 3g A mixed curing agent (80% concentration) of benzenes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com