Perovskite solar cell with ammonium thiocyanate as intermediate layer and preparation method

A solar cell, ammonium thiocyanate technology, applied in the field of solar cells, can solve the problems of affecting the contact of the light-absorbing layer of the perovskite structure, poor film quality, and many surface hydroxyl groups, so as to promote carrier transport and reduce the formation of NiOOH. , good photoelectric performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

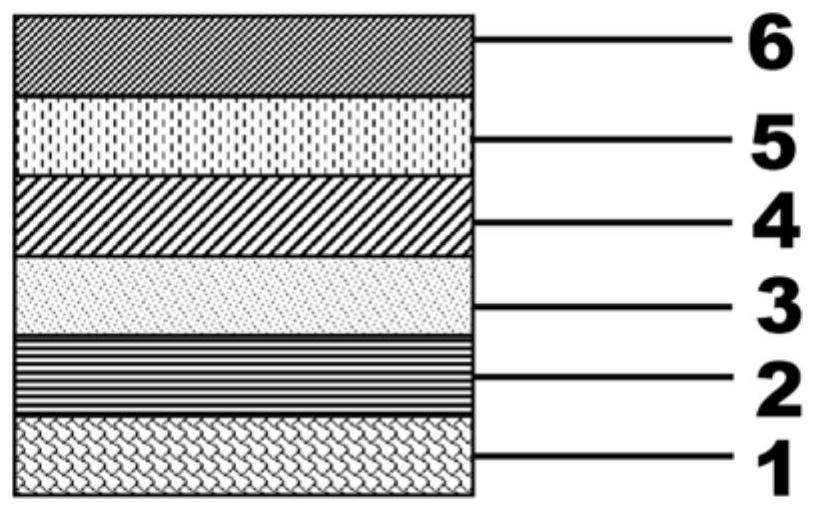

[0039] The preparation method of above-mentioned perovskite solar cell comprises the following steps:

[0040] 1), prepare NiO with a thickness of 5-100nm on the transparent conductive substrate 1 x hole transport layer 2;

[0041] 2), after fully drying, in NiO x Coating (spin-coating) NH on the hole transport layer 2 4 SCN solution, after drying at 80-150°C for 1-30min, an ultra-thin NH with a thickness of 2-20nm is formed 4 SCN middle layer 3;

[0042] Among them, NH 4 The solvent used in the SCN solution is a volatile solvent, preferably ethanol, N-N dimethylformamide (DMF) or water.

[0043] NH 4 The concentration range of SCN solution is 0.05-20.00mg / mL.

[0044] 3), in NH 4 Coating a perovskite thin film on the SCN intermediate layer 3 to form a perovskite structure light-absorbing layer 4 with a thickness of 300-500nm, and then preparing an electron transport layer 5 on the perovskite structure light-absorbing layer 4;

[0045] 4) Evaporating an electrode on t...

Embodiment 1

[0050] A kind of ammonium thiocyanate (NH 4 SCN) is NiO x The preparation method of the perovskite solar cell of the perovskite structure light-absorbing layer intermediate layer comprises the following steps:

[0051] (1) NiO x Precursor solution: Add nickel acetylacetonate and potassium acetate to the mixed solution of ethanol and acetonitrile to obtain NiO x For the precursor solution, the volume ratio of ethanol to acetonitrile is 1:19, the total concentration of nickel and potassium is 0.02mol / L, and the molar ratio of Ni:K atom is 80:20.

[0052] NiO was sprayed with a 0.3 mm caliber air spray gun x The precursor solution was sprayed on the transparent conductive substrate 1, and annealed at 450°C for 30 minutes to obtain NiO x The hole transport layer 2 has a thickness of about 30nm.

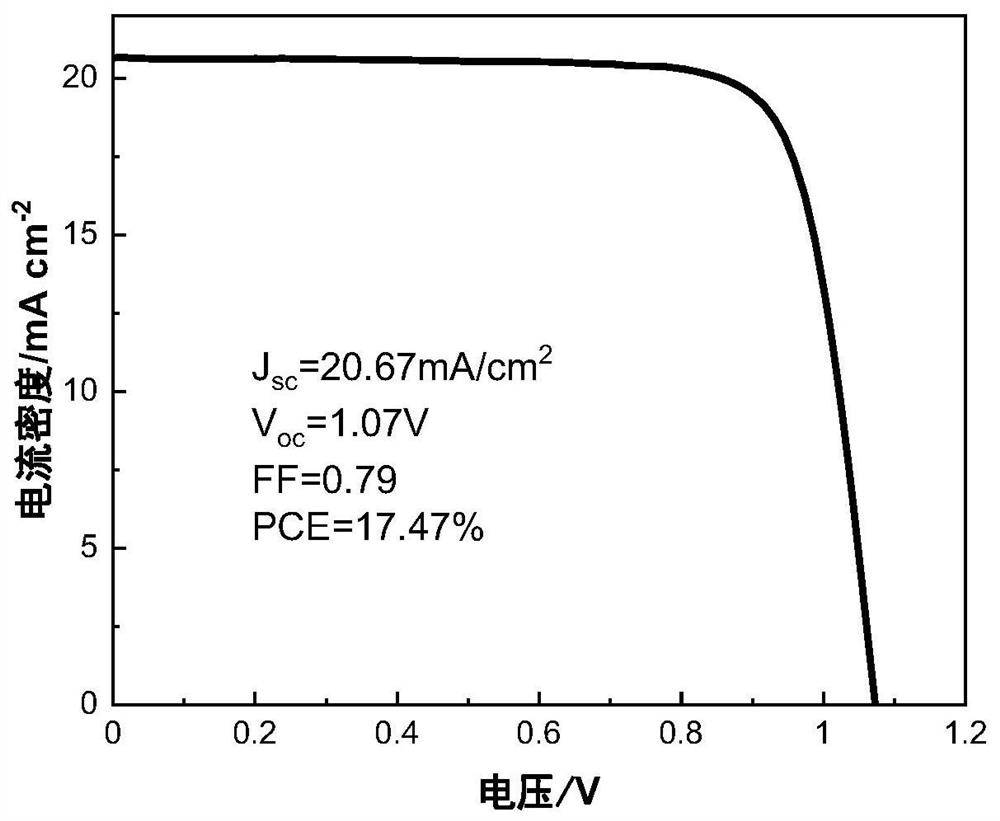

[0053] (2) A small amount of NH with a concentration of 0.20 mg / L 4 SCN ethanol solution was spin-coated on NiO at a speed of 5000rpm x On the hole transport layer 2, the spin-coat...

Embodiment 2

[0060] A kind of ammonium thiocyanate (NH 4 SCN) is NiO x The preparation method of the perovskite solar cell of the perovskite structure light-absorbing layer intermediate layer comprises the following steps:

[0061] (1) NiO x Precursor solution: Add nickel acetylacetonate, copper acetate monohydrate, lithium acetate and magnesium acetate tetrahydrate to the mixed solution of ethanol and acetonitrile to obtain NiO x For the precursor solution, the volume ratio of ethanol to acetonitrile is 1:19, the total concentration of nickel, copper, lithium and magnesium is 0.02mol / L, and the atomic molar ratio of Ni:Cu:Li:Mg is 75:10:10:5.

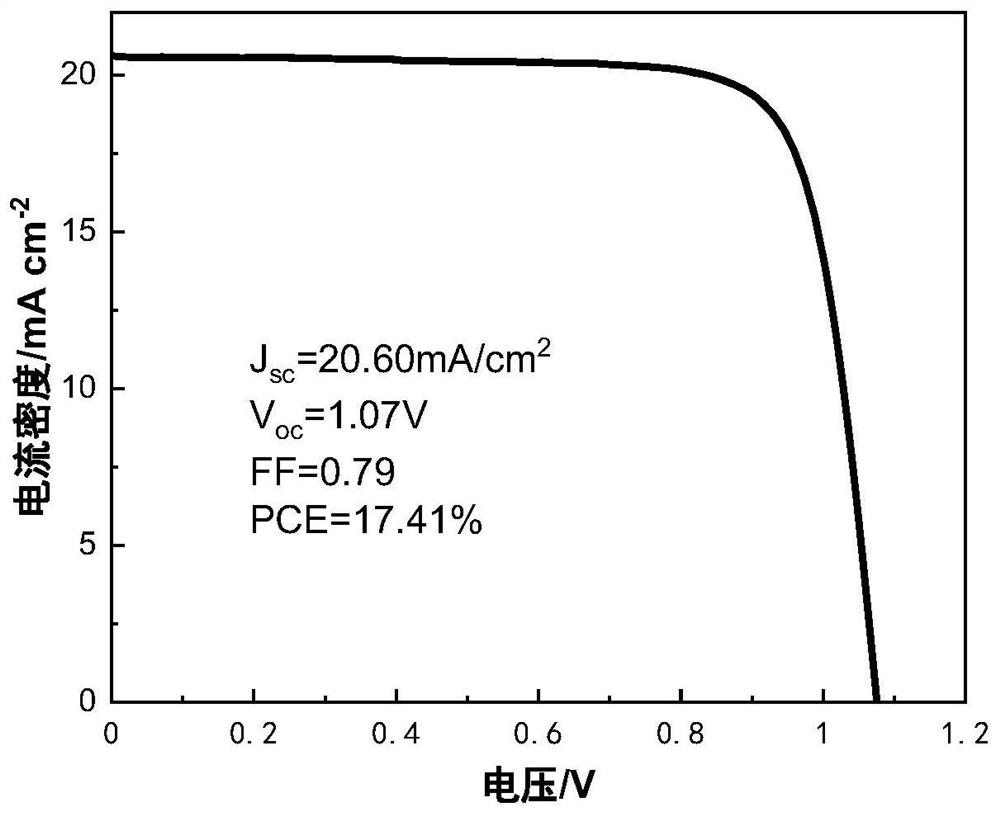

[0062] NiO was sprayed with a 0.3mm caliber spray gun x The precursor solution was sprayed on the transparent conductive substrate 1, and annealed at 500°C for 30 minutes to obtain NiO x The hole transport layer 2 has a thickness of 28nm. .

[0063] (2) A small amount of NH with a concentration of 0.50mg / L 4 SCN ethanol solution was spin-coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com