Electron transport material and preparation method thereof, light-emitting device and light-emitting device

A technology of electron transport materials and conditions, applied in the direction of electric solid devices, light-emitting materials, electrical components, etc., can solve the problems of poor stability, reduced efficiency of light-emitting devices, short lifespan, etc., achieve wide band gap, improve electron mobility, low drive The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

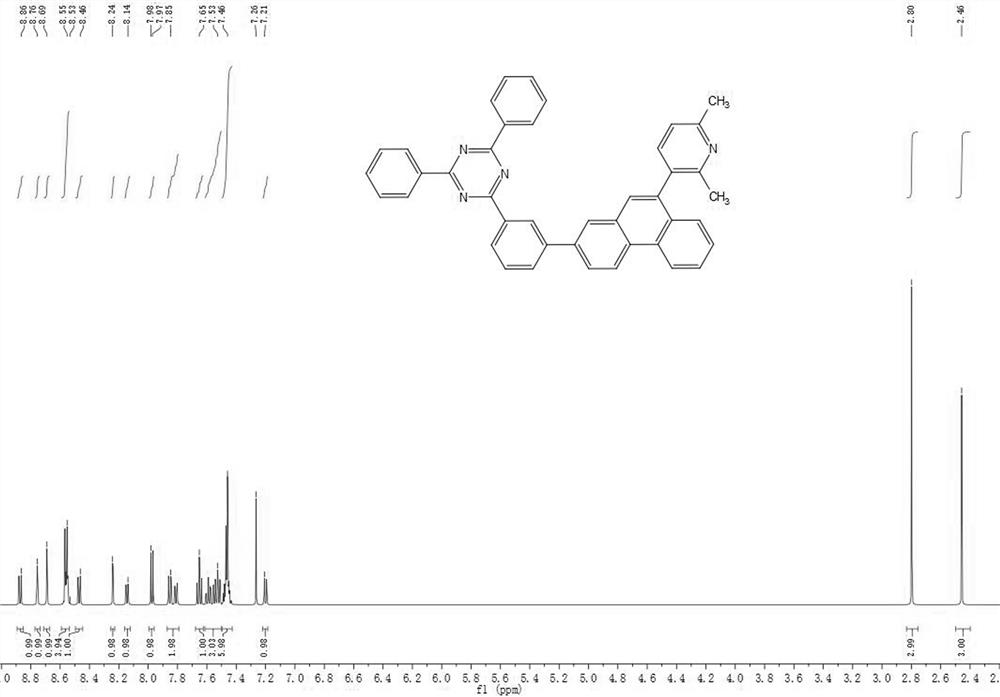

[0078] Example 1 Synthesis of Compound 1

[0079]

[0080] step 1:

[0081] N 2 Under protection, reactant A-1 (50 mmol), reactant B-1 (60 mmol), tetrakis (triphenylphosphine) palladium (0.5 mmol) and potassium carbonate (110 mmol) were added to toluene, ethanol, water (150 mL) : 50mL: 50mL) in a mixed solvent, heated to 95°C, reacted for 10h, filtered with diatomite while hot to remove salt and catalyst, after the filtrate was cooled to room temperature, the solvent was removed using a rotary evaporator, and the obtained solid was dried After passing through a silica gel funnel, the volume ratio of dichloromethane: petroleum ether was 1:6 as a developing agent, and the filtrate was removed with a rotary evaporator, and the obtained solid was dried to obtain Intermediate C-1 (13.99g, yield: 88% , Mw: 318.06).

[0082] Step 2:

[0083] N 2 Under protection, intermediate C-1 (38 mmol), reactant D-1 (45.6 mmol), palladium acetate (Pd(OAc) 2 ) (0.38mmol) and 2-cyclohexyl-...

Embodiment 2

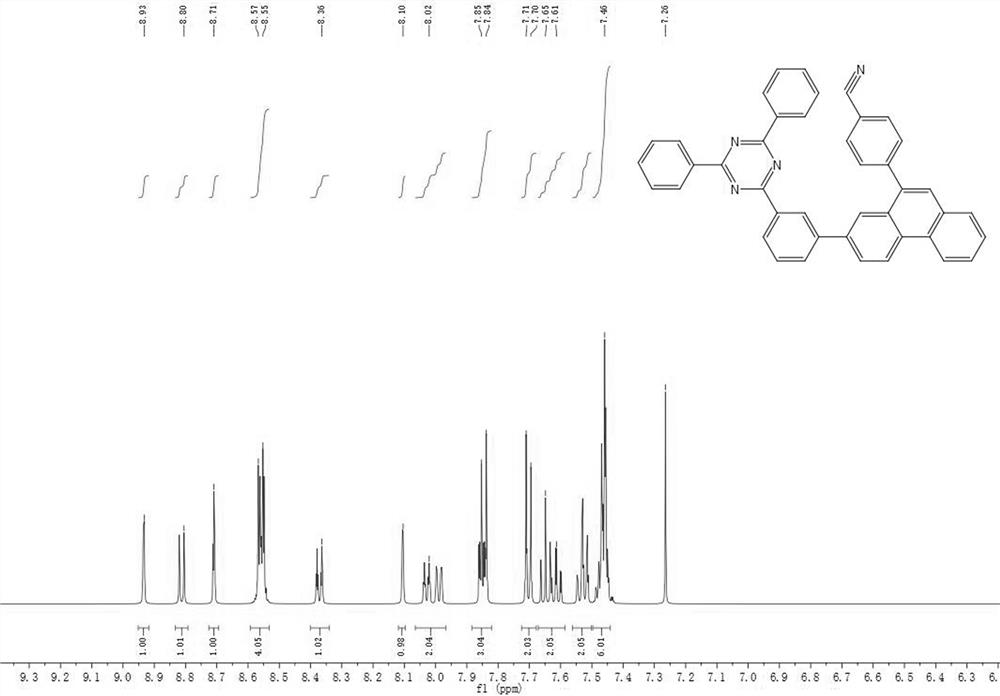

[0091] Example 2: Synthesis of Compound 93

[0092]

[0093] step 1:

[0094] N 2 Under protection, reactant A-93 (50 mmol), reactant B-93 (60 mmol), tetrakis(triphenylphosphine) palladium (0.5 mmol) and potassium carbonate (110 mmol) were added to toluene, ethanol, water (150 mL) respectively. : 50 mL: 50 mL) in a mixed solvent, heated to 95°C, reacted for 9 h, filtered with diatomaceous earth while hot to remove salt and catalyst, after the filtrate was cooled to room temperature, the solvent was removed using a rotary evaporator, and the obtained solid was dried After passing through a silica gel funnel, with dichloromethane: petroleum ether volume ratio of 1:6 as a developing agent, the filtrate was removed with a rotary evaporator, and the obtained solid was dried to obtain intermediate C-93 (16.62g, yield: 85% , Mw: 391.05).

[0095] Step 2:

[0096] N 2 Under protection, intermediate C-93 (38 mmol), reactant D-93 (45.6 mmol), palladium acetate (Pd(OAc) 2 ) (0.3...

Embodiment 3

[0103] Example 3: Synthesis of Compound 127

[0104]

[0105] step 1:

[0106] N 2 Under protection, reactant A-127 (50 mmol), reactant B-127 (60 mmol), tetrakis(triphenylphosphine) palladium (0.5 mmol) and potassium carbonate (105 mmol) were added to toluene, ethanol and water (150 mL) respectively. : 50 mL: 50 mL) in a mixed solvent, heated to 90 °C, reacted for 10 h, filtered with diatomaceous earth while hot to remove salt and catalyst, after the filtrate was cooled to room temperature, the solvent was removed using a rotary evaporator, and the obtained solid was dried After passing through a silica gel funnel, with dichloromethane: petroleum ether volume ratio of 1:5 as a developing agent, the filtrate was removed with a rotary evaporator, and the obtained solid was dried to obtain intermediate C-127 (19.02g, yield: 86% , Mw:442.31).

[0107] Step 2:

[0108] N 2 Under protection, intermediate C-127 (38 mmol), reactant D-127 (45.6 mmol), palladium acetate (Pd(OAc)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com