Graphene electrothermal film slurry, preparation method thereof and electrothermal film

A technology of graphene and electric heating film, which is applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of short service life and achieve the effect of long service life and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

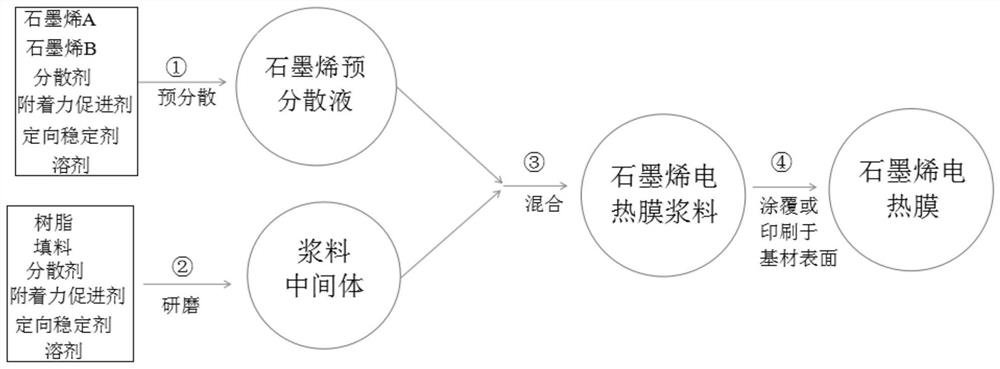

Method used

Image

Examples

Embodiment 1

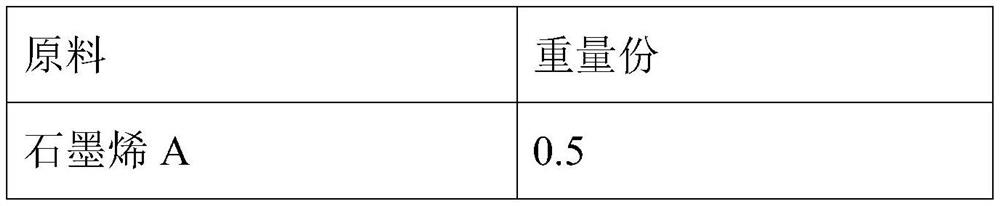

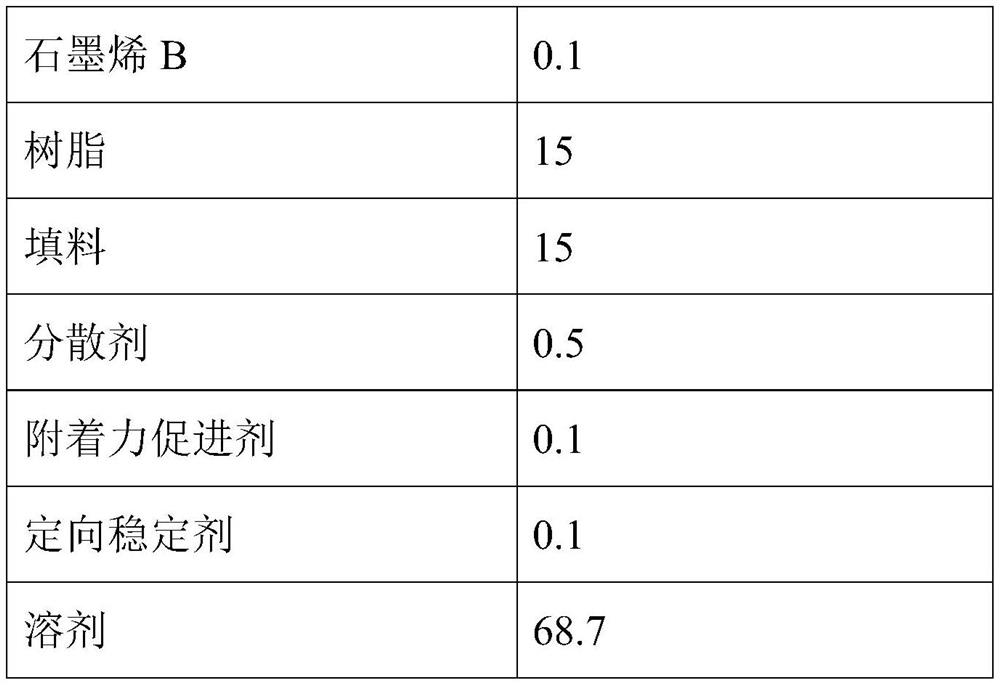

[0030] This embodiment provides a graphene electrothermal film slurry, including the components shown in Table 1 in parts by weight.

[0031] Table 1

[0032]

[0033]

[0034] The preparation of graphene electrothermal film slurry is characterized in that comprising the following steps:

[0035] (1) Graphene pre-dispersion: 0.2 part of Graphene A, Graphene B, dispersant sodium dodecylbenzenesulfonate, 0.03 part of adhesion promoter silane coupling agent KH550, orientation stabilizer ethylene-acetic acid 0.07 parts of ethylene copolymer compound LRH668, 40 parts of solvent ethanol for pre-dispersion of graphene;

[0036] (2) Preparation of the slurry intermediate: Polyurethane resin, filler graphite, 0.3 parts of the remaining dispersant sodium dodecylbenzenesulfonate, 0.07 parts of the remaining adhesion promoter silane coupling agent KH550, and the remaining directional stabilizer ethylene- Grind and disperse 0.03 parts of vinyl acetate copolymer compound LRH668 and ...

Embodiment 2

[0040] This embodiment provides a graphene electrothermal film slurry, including the components shown in Table 2 in parts by weight.

[0041] Table 2

[0042] components parts by weight Graphene A 2 Graphene B 0.5 resin 35 filler 45 Dispersant 2 orientation stabilizer 0.5 solvent 14.5 adhesion promoter 0.5

[0043] The preparation of graphene electrothermal film slurry is characterized in that comprising the following steps:

[0044] (1) Graphene pre-dispersion: Graphene A, graphene B, 1 part of dispersant BYK161, 0.2 part of adhesion promoter KMT-9000, 0.4 part of directional stabilizer polyether silicone RKZ3001, and 8.5 parts of solvent acetone Predispersion of graphene;

[0045] (2) Preparation of the slurry intermediate: acrylic resin, filler conductive carbon black, 1 part of the remaining dispersant Afcona4010, 0.3 part of the remaining adhesion promoter KMT-9713, 0.1 part of the remaining orientation sta...

Embodiment 3

[0049] This embodiment provides a graphene electrothermal film slurry, including the components shown in Table 3 in parts by weight.

[0050] table 3

[0051] components parts by weight Graphene A 1 Graphene B 0.2 resin 25 filler 32 Dispersant 1.5 orientation stabilizer 0.35 solvent 39.55 adhesion promoter 0.4

[0052] The preparation of graphene electrothermal film slurry is characterized in that comprising the following steps:

[0053] (1) Graphene pre-dispersion: Graphene A, Graphene B, 0.5 part of dispersant sodium dodecylsulfonate, 0.5 part of Afcona5008, 0.2 part of adhesion promoter titanate coupling agent 101, directional stability 0.3 part of polyamide wax 229, 0.03 part of directional stabilizer 201P, 5 parts of solvent tetrahydrofuran, and 10 parts of ethylene glycol are used to pre-disperse graphene;

[0054] (2) Preparation of slurry intermediate: 20 parts of polyester resin, 5 parts of ethylene vin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com