Preparation method of phthalate magnetic molecularly imprinted polymer extraction material

A technology of phthalic acid and imprinted polymers, applied in alkali metal compounds, chemical instruments and methods, water pollutants, etc., can solve problems such as increasing the cost of environmental samples, interference in chromatographic analysis, and poor selectivity of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

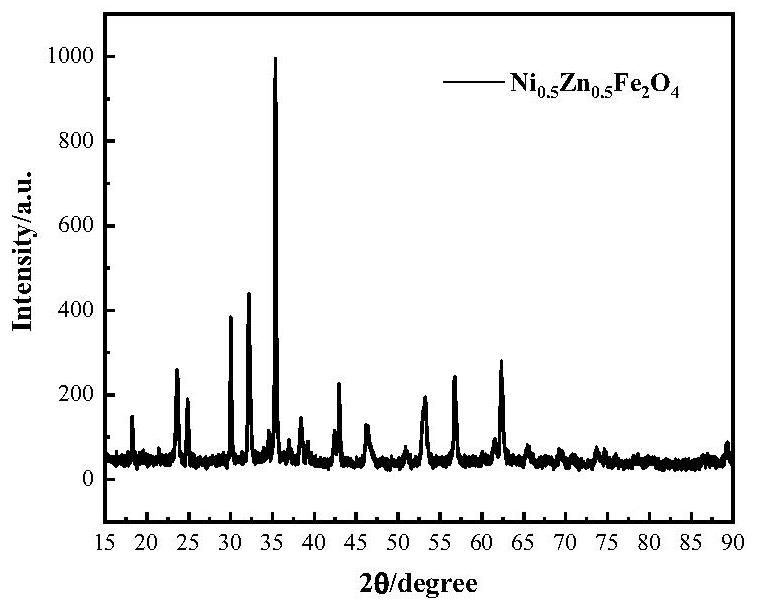

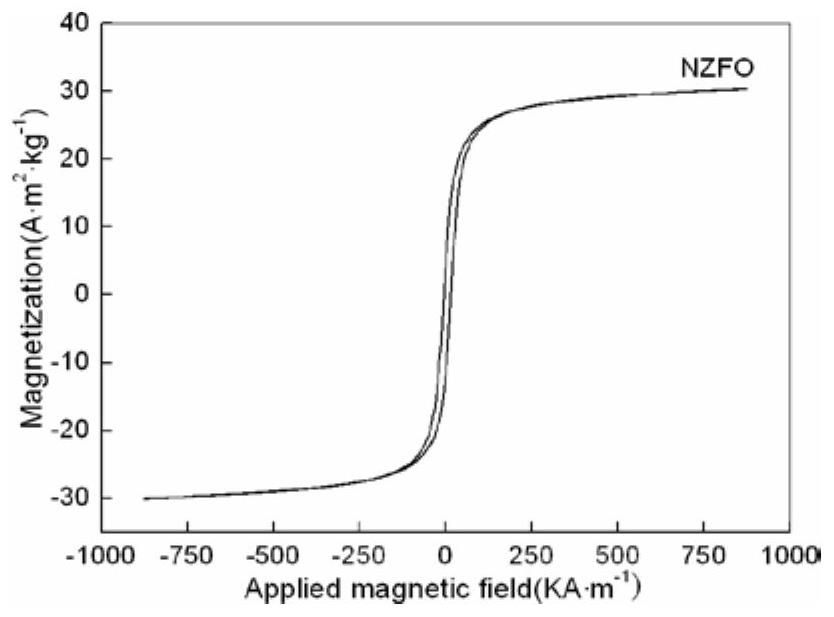

[0035] (1) Weigh 2.2500g urea and 0.8325g CTAB and add them into 140mL of deionized water and ultrasonically to a clear solution, continue to add 3.6000g (NH4)2Fe(SO4)2·6H2O and stir, add 0.6674g Ni ( NO3)2·6H2O and 0.6827g Zn(NO3)2·6H2O were stirred for 10min, then transferred to a 200mL hydrothermal reactor, and reacted at 160°C for 6h. The obtained Ni0.5Zn0.5Fe2O4 magnetic core was washed three times with ethanol and deionized water respectively, the product was collected by a magnet, and dried in vacuum at 80°C for 12h.

[0036](2) Weigh 700 mg of the magnetic nucleus synthesized in step (1) and ultrasonically disperse it in a mixed solution of 50 mL of deionized water and ethanol (1:4, V / V). Ethyl silicate was stirred at room temperature for 6 hours. The obtained product was separated by a magnet, washed three times with ethanol and deionized water, and dried in vacuum at 50°C for 12 hours to obtain Ni0.5Zn0.5Fe2O4@SiO2 nanoparticles.

[0037] (3) Add 5mL of 3-aminopropy...

Embodiment 2

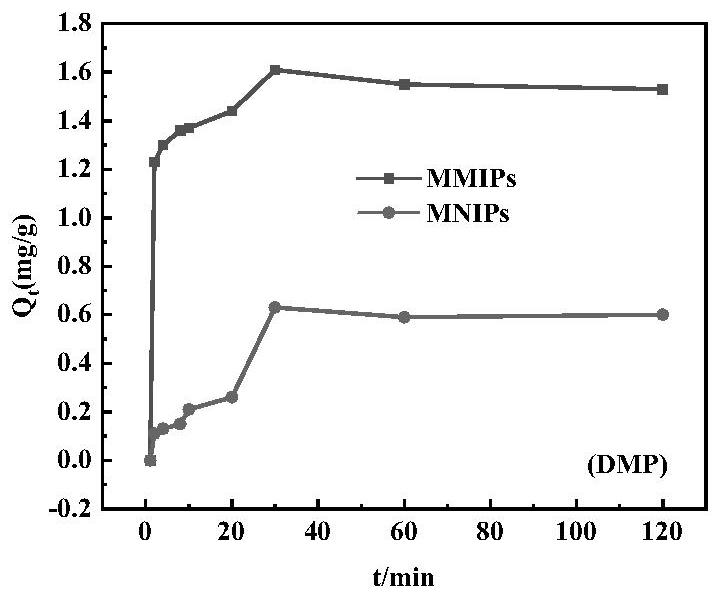

[0053] The difference from Example 1 is that the molar ratio of the template molecule (dimethyl phthalate or dipropyl phthalate) to the functional monomer (methacrylic acid) is 1:2, and the functional monomer and crosslinking agent, the molar ratio of the functional monomer to the crosslinking agent is the same as in Example 1, the molar ratio of the template molecule, the functional monomer to the crosslinking agent is 1:2:10, and the rest are the same as in Example 1.

Embodiment 3

[0055] The difference from Example 1 is that the molar ratio of the template molecule (dimethyl phthalate or dipropyl phthalate) to the functional monomer (methacrylic acid) is 1:6, and the functional monomer and crosslinking Agent, the molar ratio of functional monomer and crosslinking agent is the same as in Example 1, the molar ratio of template molecule, functional monomer and crosslinking agent is 1:6:30, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com