Polyaniline modified TiO2 composite nanofiber membrane as well as preparation method and application thereof

A composite nanofiber and polyaniline technology, applied in the field of mineral composite materials, can solve the problems affecting the photocatalytic ability of TiO2, achieve the effect of improving the light response range, solving the difficulty of recycling, and improving the light quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

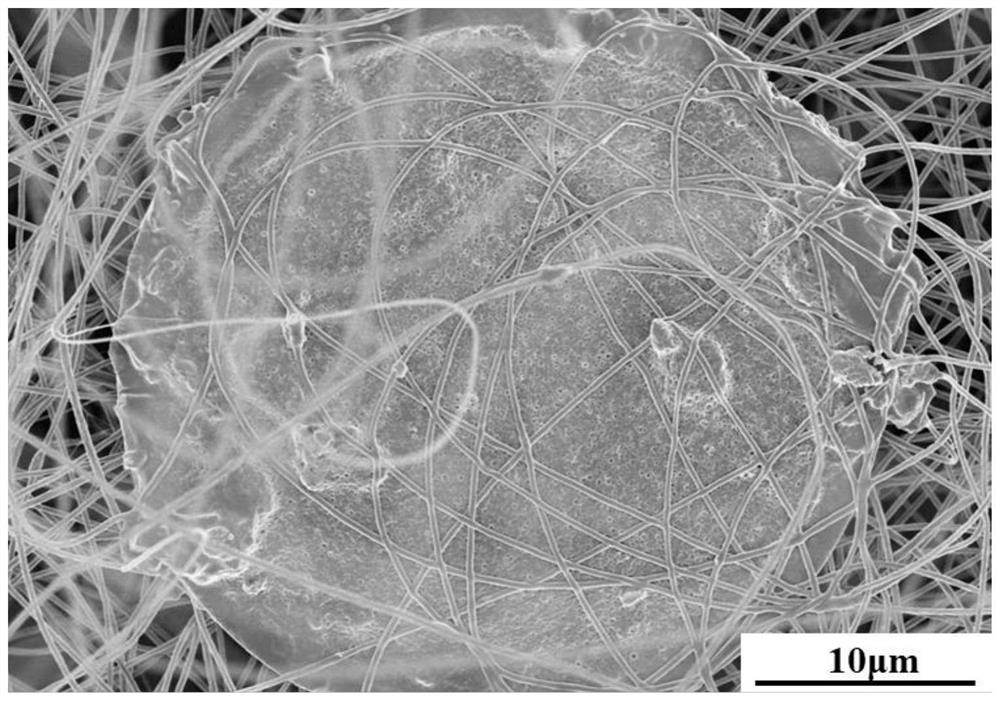

Image

Examples

preparation example Construction

[0030] The present invention also provides the above-mentioned polyaniline modified TiO 2 The preparation method of composite nanofibrous membrane comprises the following steps:

[0031] TiO 2 / diatomaceous earth composite material and hydrochloric acid are mixed to obtain TiO 2 / diatomite slurry;

[0032] The TiO 2 / Diatomite slurry, oxidant and aniline are mixed for oxidative polymerization to obtain active components;

[0033] mixing the active component with an organic polymer to obtain a spinning solution;

[0034] Electrospinning the spinning solution to form a film.

[0035] In the present invention, unless otherwise specified, the raw materials used in the present invention are preferably commercially available products.

[0036] In the present invention, TiO 2 / diatomaceous earth composite material and hydrochloric acid are mixed to obtain TiO 2 / Diatomaceous earth slurry.

[0037] In the present invention, the concentration of the hydrochloric acid is prefera...

Embodiment 1

[0057] 2g TiO 2 / diatomaceous earth composite material (TiO 2 / TiO in Diatomite Composite 2 The mass ratio to diatomaceous earth is 4:10) and 200mL of 1mol / L HCl aqueous solution at a temperature of 5°C and a rotation speed of 2000rpm, stirring for 30min to obtain TiO 2 / diatomite slurry, the TiO 2 / The solid content of the diatomite slurry is 1%.

[0058] TiO obtained above 2 / diatomite slurry, 0.098 g of ammonium persulfate and 20 μL of aniline were mixed, and stirred at a temperature of 5° C. and a rotation speed of 2000 rpm for 4 hours. Then, the feed liquid obtained by the oxidative polymerization was washed three times with an ethanol aqueous solution having a volume concentration of 50%, and the washed feed liquid was dried at 60° C. for 8 hours to obtain an active component.

[0059] 3.2g of polyacrylonitrile was dissolved in 20mLN,N-dimethylformamide, and continued to stir until polyacrylonitrile was completely dissolved to form a polyacrylonitrile solution; ...

Embodiment 2

[0062] The only difference between this example and Example 1 is that ① replace "0.098g ammonium persulfate and 20 μL aniline" with "0.294g ammonium persulfate solid and 60 μL aniline";

[0063] ②The reaction time of oxidative polymerization is replaced by "12h" from "4h";

[0064] ③ Modify the mass of the active component from 0.32g to 0.64g. The polyaniline modified TiO that embodiment 2 prepares 2 The thickness of the composite nanofibrous membrane is 55 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com