Antibacterial and antiviral treatment process for workpiece

A treatment process and anti-virus technology, which is applied in the direction of pre-treatment surface, paint containing biocide, device for coating liquid on the surface, etc., can solve the problems such as the decline in the durability of the coating and the lack of antibacterial and anti-virus functions on the surface of the workpiece. Achieve the effect of maintaining hardness and wiping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

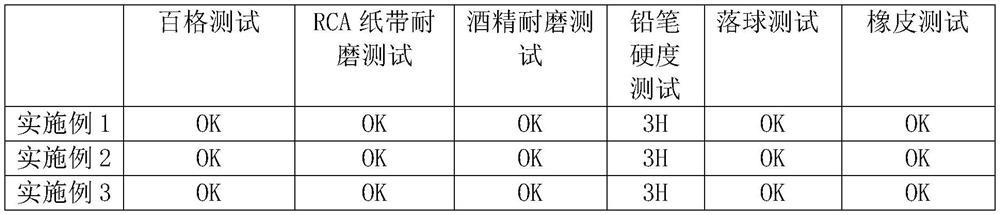

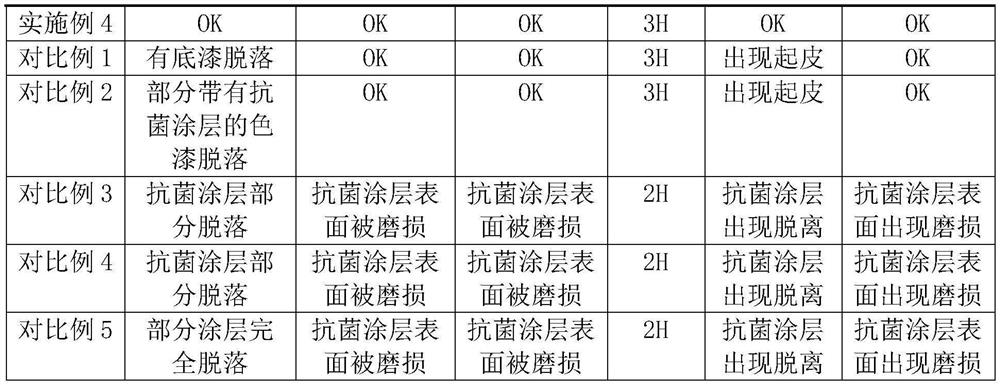

Embodiment 1

[0025] The antibacterial and antiviral treatment process of the workpiece includes the following steps:

[0026] First of all, the surface of the workpiece is pretreated, and different pretreatment steps are performed according to the material of the workpiece. For aluminum alloys, magnesium aluminum alloys, magnesium lithium alloys, stainless steel and plastic-coated parts of these alloys, grinding and Oxidation treatment step, wherein the plastics in the plastic lagging are mainly polyphenyl sulfide resin, polyphenyl sulfide resin containing glass fiber, polybutylene terephthalate and polyterephthalate containing glass fiber Butylene formate;

[0027] Then, spray the primer on the pretreated workpiece surface. The primer is prepared from 40kg of acrylic resin, 20kg of amino resin, 5kg of butyl ester, 5kg of ethylene glycol butyl ether, 2kg of cellulose acetate butyrate additive, and 2kg of pigment. After primer, bake at 100°C for 20 minutes to dry, so that a primer layer wi...

Embodiment 2

[0031] The antibacterial and antiviral treatment process of the workpiece includes the following steps:

[0032] First of all, the surface of the workpiece is pretreated, and different pretreatment steps are performed according to the material of the workpiece. For aluminum alloys, magnesium aluminum alloys, magnesium lithium alloys, stainless steel and plastic-coated parts of these alloys, grinding and Oxidation treatment step, wherein the plastics in the plastic lagging are mainly polyphenyl sulfide resin, polyphenyl sulfide resin containing glass fiber, polybutylene terephthalate and polyterephthalate containing glass fiber Butylene formate;

[0033] Then, spray the primer on the pretreated workpiece surface. The primer is prepared from 50kg of acrylic resin, 25kg of amino resin, 10kg of butyl ester, 10kg of ethylene glycol butyl ether, 5kg of cellulose acetate butyrate additive, and 3kg of pigment. After primer, bake at 130°C for 40 minutes to dry, so that a primer layer ...

Embodiment 3

[0037] The antibacterial and antiviral treatment process of the workpiece includes the following steps:

[0038] First of all, the surface of the workpiece is pretreated, and different pretreatment steps are performed according to the material of the workpiece. For aluminum alloys, magnesium aluminum alloys, magnesium lithium alloys, stainless steel and plastic-coated parts of these alloys, grinding and Oxidation treatment step, wherein the plastics in the plastic lagging are mainly polyphenyl sulfide resin, polyphenyl sulfide resin containing glass fiber, polybutylene terephthalate and polyterephthalate containing glass fiber Butylene formate;

[0039] Then, spray the primer on the pretreated workpiece surface. The primer is prepared from 45kg of acrylic resin, 22kg of amino resin, 6kg of butyl ester, 8kg of ethylene glycol butyl ether, 3kg of cellulose acetate butyrate auxiliary agent, and 2kg of pigment. After primer, bake at 120°C for 30 minutes to dry, so that a primer l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com