Bactericide for sulfate reducing bacteria in polymer-containing produced liquid as well as preparation method and application of bactericide

A sulfate and fungicide technology, applied in the field of fungicides and preparations of sulfate-reducing bacteria in polymer-containing production fluids, can solve the problem of affecting the viscosity of polymer-containing production fluids, affecting the use of fungicides, and reducing the use of agents and other problems, to achieve excellent bactericidal effect, good adaptability, and low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

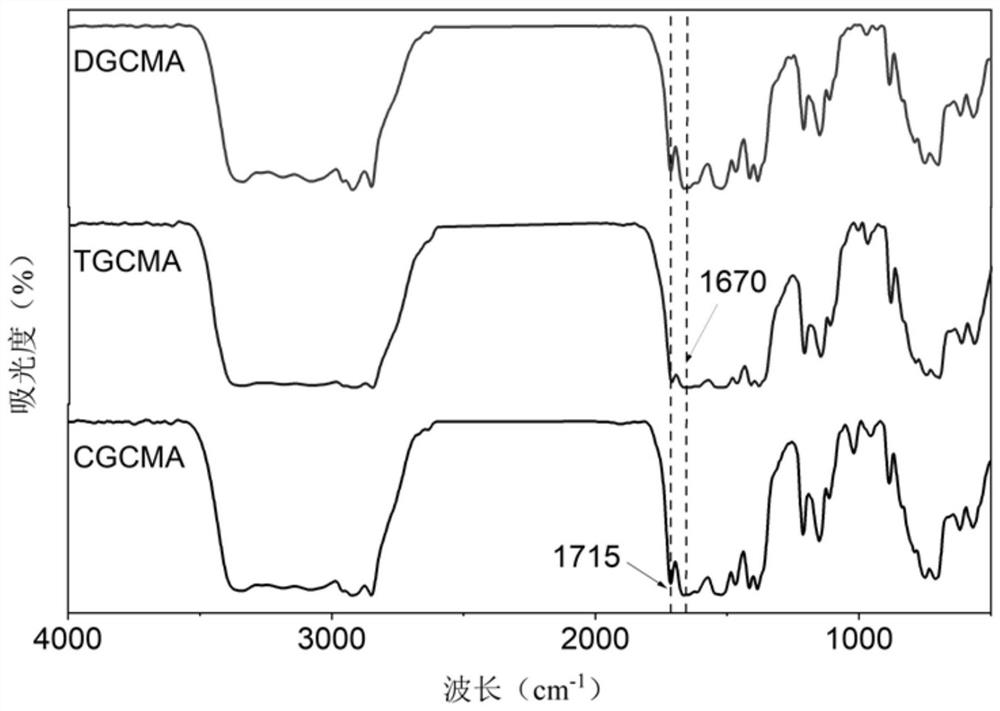

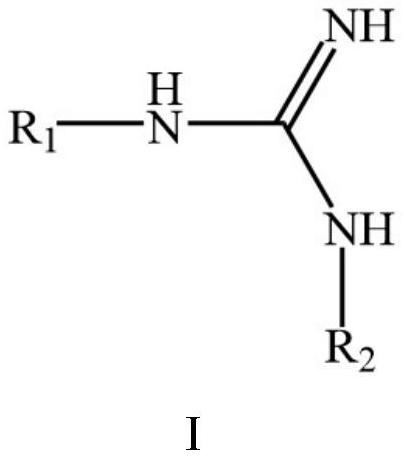

[0047] Embodiment 1: Bactericide DGCMA and its preparation method and application method

[0048] A fungicide DGCMA used for sulfate-reducing bacteria in poly-containing production fluid has the following structure:

[0049]

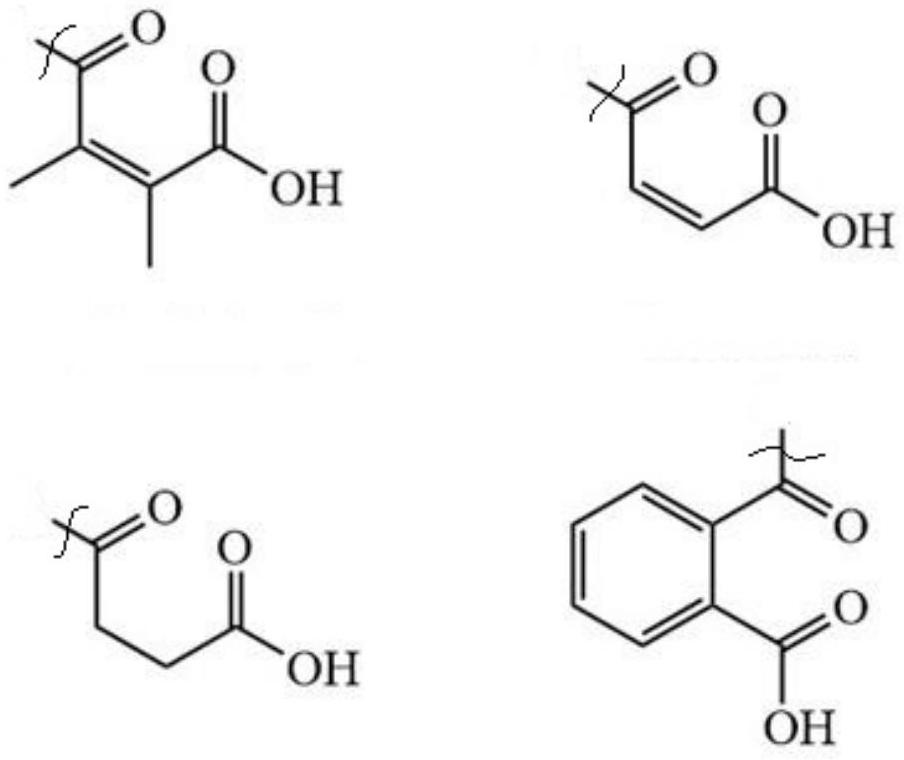

[0050] The preparation method of above-mentioned bactericide DGCMA

[0051] ① Weigh 1.0312g of dodecylamine and 1.0200g of 1H-pyrazole-1-carboxamidine hydrochloride, put them in a flask, add 10mL of methanol as solvent, then raise the temperature to 40°C, stir at 200r / min, and stir After 48 hours, after the reaction was completed, the solvent methanol was distilled off under reduced pressure, acetone was added for recrystallization, a solid sample was obtained by suction filtration, and an intermediate product was obtained after vacuum drying, with a molar yield of 74.35%;

[0052] ②Weigh 0.5368g of the above intermediate, 0.2620g of 2,3-dimethylmaleic anhydride, 0.5224g of N,N-diisopropylethylamine, put them in a flask, add 5mL of dichloromethane an...

Embodiment 2

[0057] Embodiment 2: fungicide TGCMA and its preparation method and application method

[0058] A bactericide TGCMA used for sulfate-reducing bacteria in poly-containing production fluid has the following structure:

[0059]

[0060] The preparation method of above-mentioned bactericide TGCMA

[0061] ①Weigh 2.1384g of the above tetradecylamine and 1.6230g of 1H-pyrazole-1-carboxamidine hydrochloride, put them into a flask, add 20mL of methanol as a solvent, then raise the temperature to 40°C, and stir at a rate of 200r / min. Reacted for 48 hours. After the reaction, the solvent methanol was distilled off under reduced pressure, acetone was added for recrystallization, a solid sample was obtained by suction filtration, and an intermediate product was obtained after vacuum drying with a molar yield of 82.30%;

[0062] ②Weigh 0.5884g of the above intermediate, 0.2534g of 2,3-dimethylmaleic anhydride, 0.5334g of N,N-diisopropylethylamine, put them in a flask, add 5mL of dichlo...

Embodiment 3

[0067] Embodiment 3: bactericide CGCMA and its preparation method and application method

[0068] A fungicide CGCMA used for sulfate-reducing bacteria in poly-containing production fluid has the following structure:

[0069]

[0070] The preparation method of above-mentioned bactericide CGCMA

[0071] ① Weigh 2.4218g of the above-mentioned hexadecylamine and 1.6357g of 1H-pyrazole-1-carboxamidine hydrochloride, put them in a flask, add 20mL of methanol as a solvent, then raise the temperature to 40°C, and stir at a rate of 200r / min. Reacted for 48 hours. After the reaction, the solvent methanol was distilled off under reduced pressure, acetone was added for recrystallization, a solid sample was obtained by suction filtration, and an intermediate product was obtained after vacuum drying, with a molar yield of 84.17%;

[0072] ②Weigh 2.2163g of the above intermediate, 1.0034g of 2,3-dimethylmaleic anhydride, 2.1077g of N,N-diisopropylethylamine, put them into a flask, add 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com