Multi-effect membrane distillation and multi-effect evaporation comprehensive crystallization device

A technology of multi-effect membrane distillation and multi-effect evaporation, which is applied in the field of multi-effect membrane distillation and multi-effect evaporation comprehensive crystallization device, can solve the problems of high operating cost, strong corrosion of salt solution, large power consumption, etc., and achieve the optimization of the whole device , the effect of good investment returns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, the technical partial stamp in the embodiment of the present invention will be clearly described, and it is understood that the described embodiments are merely, not all of the embodiments of the present invention, not all of the embodiments of the invention . Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

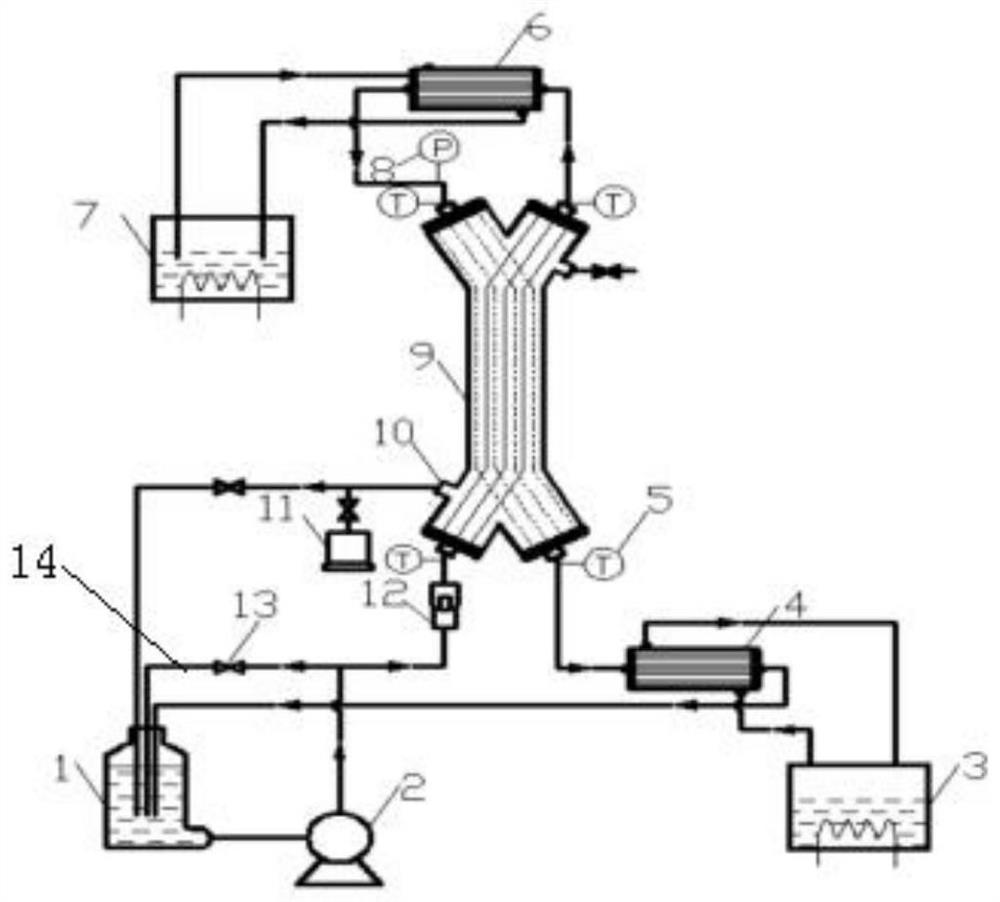

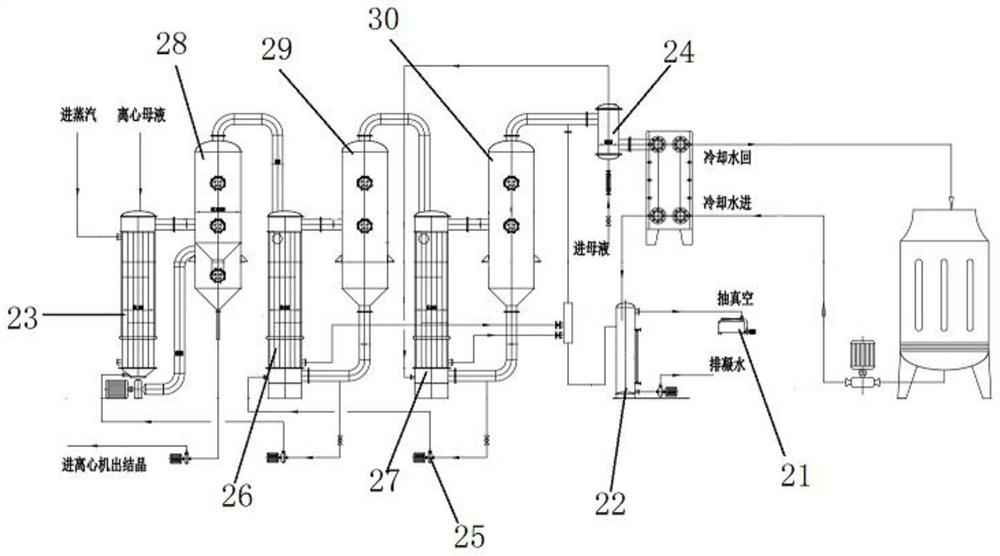

[0026] Append Figure 1-2 As shown, a multi-active film distillation and a multi-effect evaporation integrated crystallization device include a multi-active film distillation system and a multi-effect evaporation system that are sequentially connected;

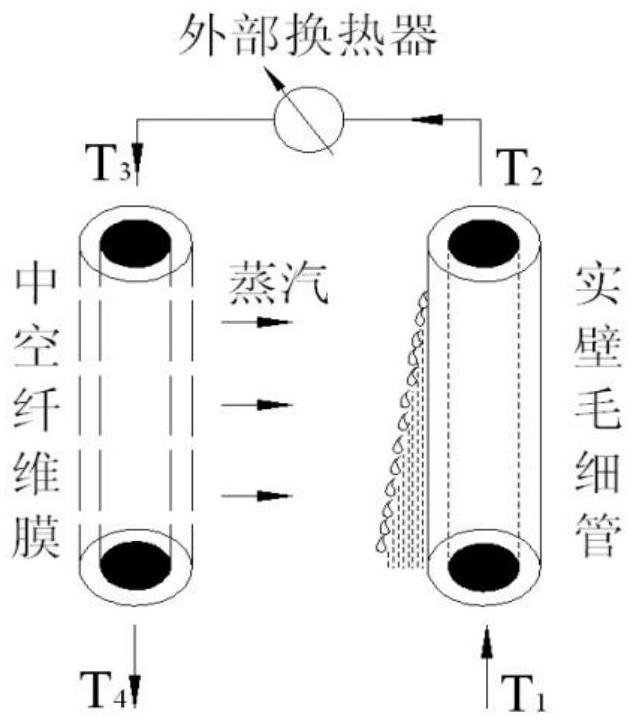

[0027] A multi-effect membrane distillation assembly includes a multi-effect membrane distillation assembly, a multi-effect membrane distillation assembly is a air gap film distillation assembly having an internal latent heat recovery function, and a multi-effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com