Method for preparing candesartan through continuous flow of microreactor

A technology of microreactor and candesartan, which is applied in the field of continuous flow preparation of candesartan by microreactor, can solve the problems of high production cost and long reaction time, and reduce the generation of by-products and solvents The effect of usage amount and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A microreactor comprising unit A, unit B and unit C for continuous flow reaction is selected for the following reactions.

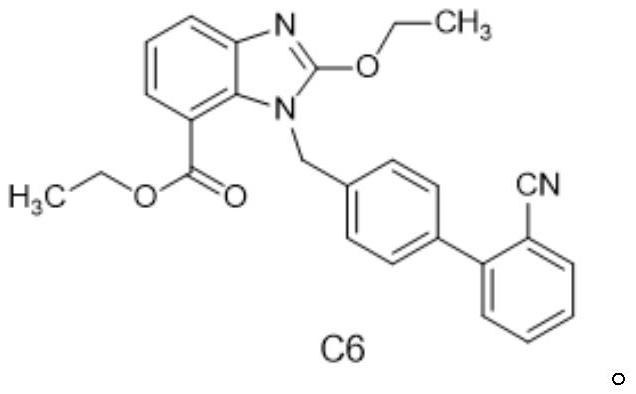

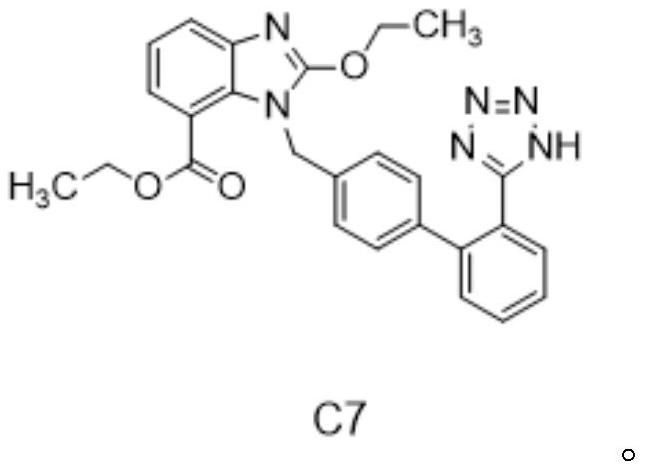

[0052] Configure 365g / L sodium azide aqueous solution in a 1L three-necked flask, flow into unit A of the microreactor at a flow rate of 75ml / min, and simultaneously pump tri-n-butyltin chloride into the microreactor at a flow rate of 110ml / min Unit A of the microreactor, the residence time of the reaction is 34 seconds, and the reaction temperature is controlled at 30°C; after the reaction liquid flows from unit A of the microreactor into unit B, the prepared 270g / L xylene solution dissolved in C6 Simultaneously pump into unit B of the microreactor at a flow rate of 260 ml / min, the residence time of the reaction unit is 72 seconds, and the reaction temperature is controlled at 175°C.

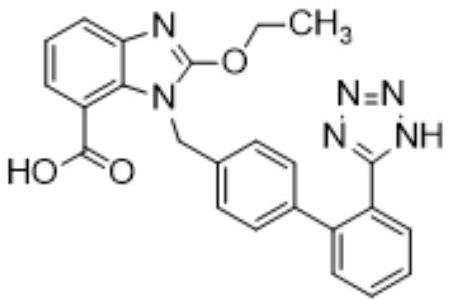

[0053]After the reaction liquid flows into the C unit from the B unit, the sodium hydroxide solution of 105g / L is pumped into the C unit of the microreactor at a fl...

Embodiment 2~6

[0055] According to the corresponding addition amount of raw materials and reaction conditions in Table 1, referring to the preparation process in Example 1, the preparation of candesartan in Examples 2-6 was carried out.

[0056] Raw material addition and reaction conditions of different embodiments of table 1

[0057]

[0058]

[0059] Known by embodiment 1~6, the purity of the product of production is all more than 98%, and product yield is all more than 87%, illustrates that adopting the method of the present invention to prepare candesartan can effectively improve the yield and purity of product, reduce Production cost; and the reaction time is short, the operation steps are simple, continuous and automatic production can be realized, and the safety is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com