MEMS temperature, humidity and pressure three-in-one sensor chip and manufacturing process thereof

A sensor chip and a three-in-one technology, applied in the field of sensors, can solve the problems of lack of convenient design of composite temperature, humidity and pressure measurement functions, unfavorable overall size control of smart products, and inability to effectively reduce parasitic capacitance, etc., to achieve a wide range of applications and convenient and compact , Realize mass production and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

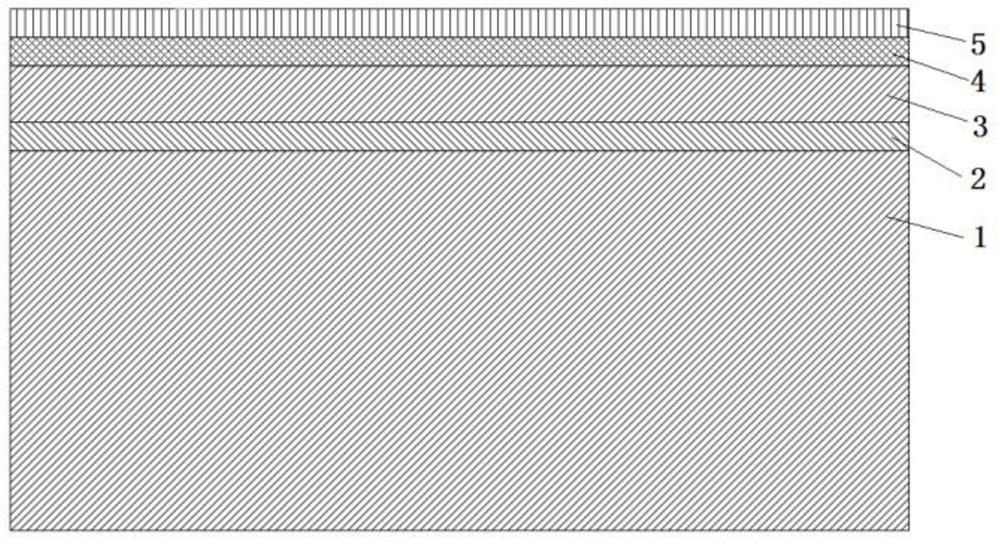

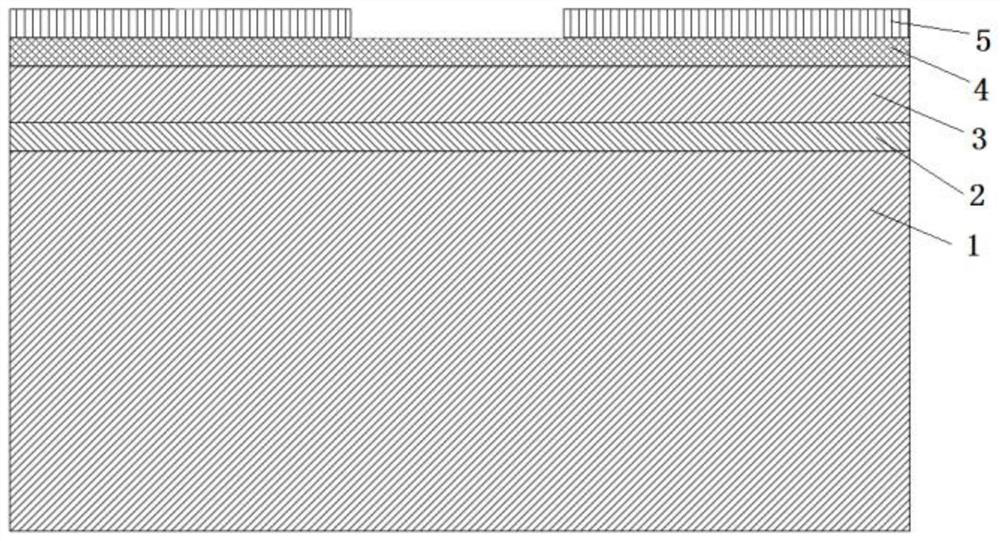

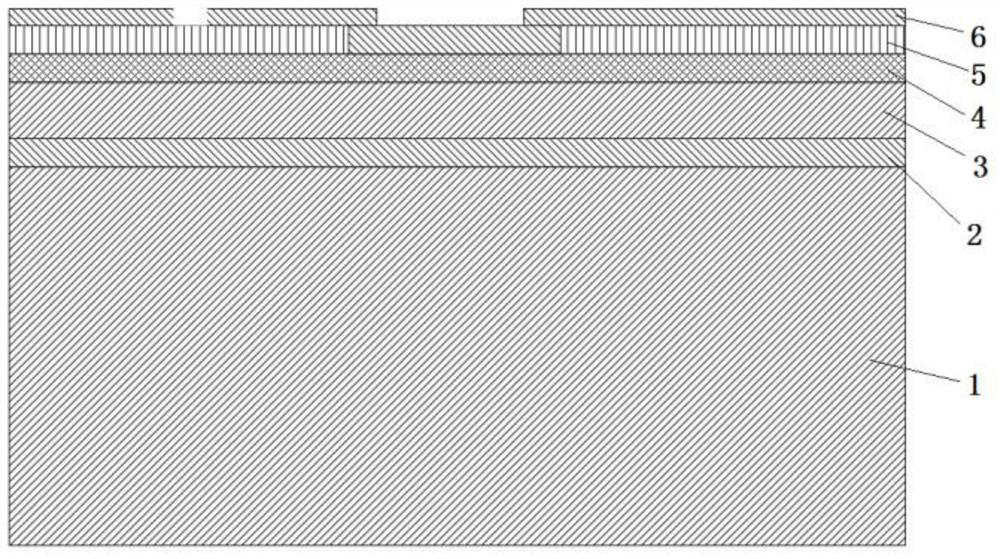

[0028] refer to Figure 1 to Figure 6 , this embodiment provides a MEMS temperature, humidity and pressure three-in-one sensor chip, including an SOI wafer, the SOI wafer includes a bulk silicon layer 1 with a thickness of 300 μm, a buried oxide layer 2 with a thickness of 0.2 μm, and a device silicon layer 3 with a thickness of 30 μm. A layer of ALN is grown on the wafer as a protective layer 4, and a layer of metal film 5 is grown outside the protective layer 4 with a thickness of 0.2um, such as figure 1 As shown, here we use metal Mo, because the temperature coefficient of resistance of Mo is similar to that of Pt, and it is also compatible with CMOS, which can be effectively applied to MEMS chips. Utilize photolithography and etching to carry out patterning on metal film 5, as figure 2 As shown, the temperature measuring resistance and the pressure measuring resistance are constructed, and the temperature measuring resistance is four resistance wires with a serpentine st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com