Co-production process for catalytic oxidation of PTA hydrogen extraction tail gas and methanol hydrogen production

A technology of methanol hydrogen production and catalytic oxidation, which is applied in hydrogen/synthesis gas production, hydrogen, hydrogen separation, etc., can solve the problems that the heat of PTA tail gas cannot be used reasonably, and the tail gas pollutes the environment, so as to reduce steam consumption and comprehensively Energy consumption reduction, device safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

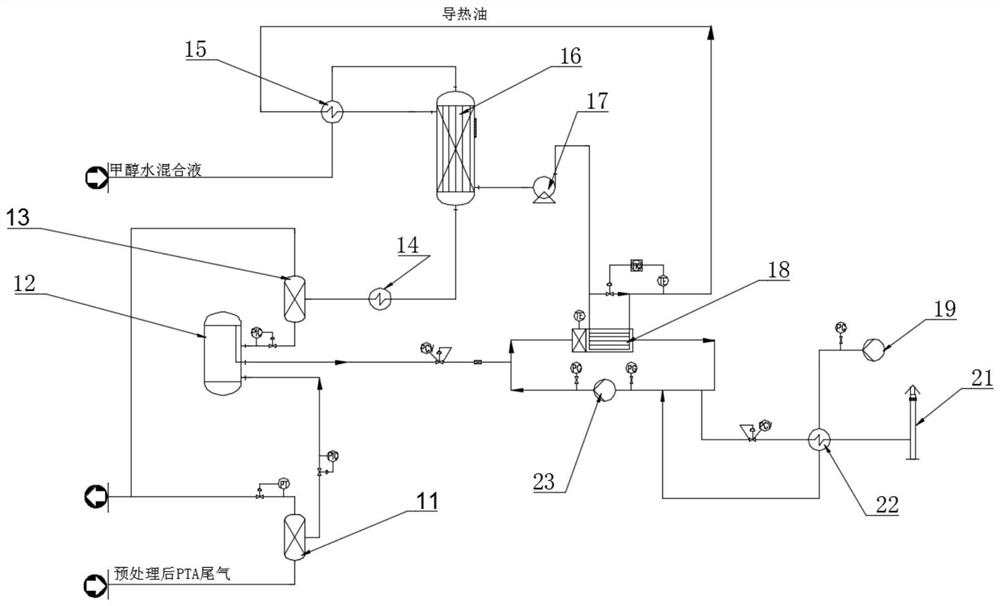

[0036] refer to figure 1 , the present invention provides a co-production process of PTA hydrogen extraction tail gas catalytic oxidation and methanol hydrogen production, including methanol hydrogen production process and PTA hydrogen extraction tail gas catalytic oxidation process;

[0037] The methanol hydrogen production process is to pass the mixed liquid of methanol and water through the vaporization superheater 15, the converter 16, and the cooling separator 14 to obtain the medium gas, and pass the medium gas into the PSA-1 13 for separation, and most of the The hydrogen with higher purity and the remaining medium gas enter the tail gas buffer tank 12; the vaporization superheater 15 and the converter 16 are connected with heat conduction oil pipes; the heat conduction oil is circulated through the heat conduction oil pump 17.

[0038] The PTA hydrogen extraction tail gas catalytic oxidation process is to separate the pretreated PTA tail gas through the PSA-2 11 to sep...

Embodiment 2

[0041] refer to figure 1 , the present invention provides a co-production process of PTA hydrogen extraction tail gas catalytic oxidation and methanol hydrogen production, including methanol hydrogen production process and PTA hydrogen extraction tail gas catalytic oxidation process;

[0042] The methanol hydrogen production process is to pass the mixed liquid of methanol and water through the vaporization superheater 15, the converter 16, and the cooling separator 14 to obtain the medium gas, and pass the medium gas into the PSA-1 13 for separation, and most of the The hydrogen with higher purity and the remaining medium gas enter the tail gas buffer tank 12; the vaporization superheater 15 and the converter 16 are connected with heat conduction oil pipes; the heat conduction oil is circulated through the heat conduction oil pump 17.

[0043] The PTA hydrogen extraction tail gas catalytic oxidation process is to separate the pretreated PTA tail gas through the PSA-2 11 to separ...

Embodiment 3

[0046] refer to figure 1 , the present invention provides a co-production process of PTA hydrogen extraction tail gas catalytic oxidation and methanol hydrogen production, including methanol hydrogen production process and PTA hydrogen extraction tail gas catalytic oxidation process;

[0047] The methanol hydrogen production process is to pass the mixed liquid of methanol and water through the vaporization superheater 15, the converter 16, and the cooling separator 14 to obtain the medium gas, and pass the medium gas into the PSA-1 13 for separation, and most of the The hydrogen with higher purity and the remaining medium gas enter the tail gas buffer tank 12; the vaporization superheater 15 and the converter 16 are connected with heat conduction oil pipes; the heat conduction oil is circulated through the heat conduction oil pump 17.

[0048] The PTA hydrogen extraction tail gas catalytic oxidation process is to separate the pretreated PTA tail gas through the PSA-2 11 to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com