Method for preparing quartz glass product with complex shape by fusion casting method

A quartz glass and complex shape technology, applied in glass pressing, glass molding, glass manufacturing equipment, etc., can solve the problems of low production efficiency, increased production cost, low utilization rate of raw materials, etc., to achieve cost saving, stable production capacity, Quality Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

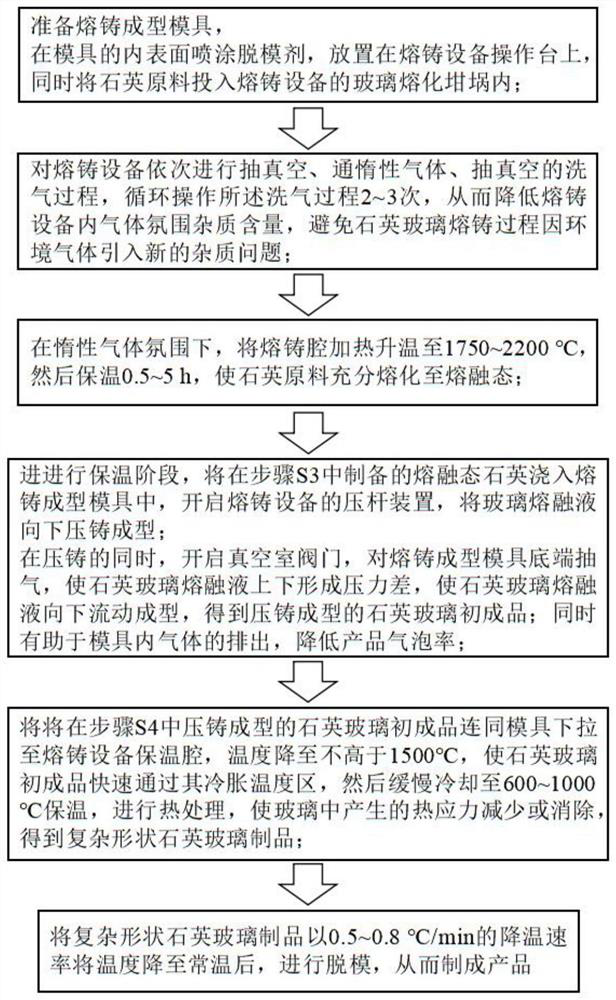

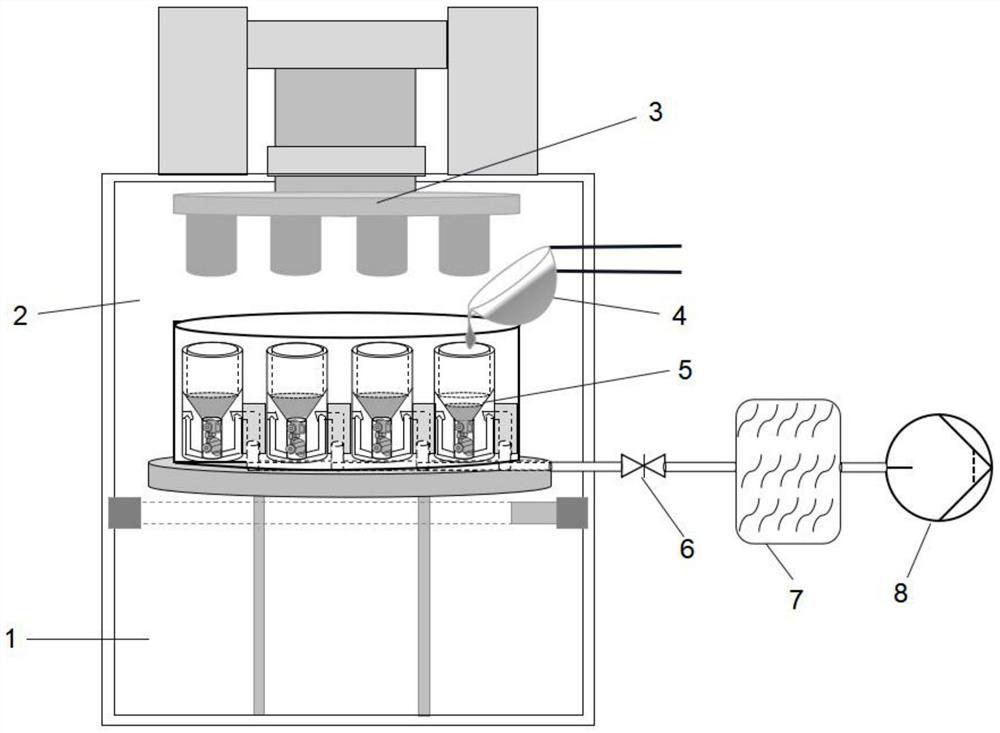

[0037] refer to figure 1 and 2 , a method for preparing complex-shaped quartz glass products by melting and casting, comprising the following steps of melting and casting:

[0038] S1. Preparation of equipment and raw materials: Prepare the melting and casting molding mold, spray the release agent on the inner surface of the mold, place it on the operation table of the melting and casting equipment, and put the quartz raw material into the glass melting crucible of the melting and casting equipment at the same time;

[0039] S2. Gas washing: Carry out the washing process of vacuuming, inert gas, and vacuuming in sequence on the melting and casting equipment, and cycle the washing process for 2 to 3 times, thereby reducing the impurity content of the gas atmosphere in the melting and casting equipment and avoiding the melting and casting of quartz glass The process introduces new impurities due to ambient gas;

[0040] S3. Fused quartz glass: in an inert gas atmosphere, the p...

Embodiment 2

[0046] A method for preparing complex-shaped quartz glass products by melting and casting, comprising the following steps of melting and casting:

[0047] Steps S1 and S2 are the same as those in Embodiment 1 and will not be described in detail;

[0048] S3. Fused quartz glass:

[0049] In an inert gas atmosphere, the air pressure is maintained at 1.5×10 5 Pa, heat up to 1500°C at a rate of 0.1°C / min, then slowly raise the temperature to 1850°C at a rate of 2.5°C / min, and then keep warm for 2 hours to completely melt the quartz raw material to a molten state;

[0050] S4. Quartz glass molding:

[0051] In the heat preservation stage, the molten quartz prepared in step S3 is poured into the casting mold, the pressing rod device of the melting and casting equipment is opened, and the molten glass is molded downward; the ambient temperature of the die-casting process is 1850°C, and the pressing rod force is 250N, the die-casting speed is 0.7mm / min, and the holding time is 1h. ...

Embodiment 3

[0058] A method for preparing complex-shaped quartz glass products by melting and casting, comprising the following steps of melting and casting:

[0059] Steps S1 and S2 are the same as those in Embodiment 1 and will not be described in detail;

[0060] S3. Fused quartz glass: in an inert gas atmosphere, the pressure is maintained at 1.9×10 5 Pa, heat up to 1500°C at a rate of 1.0°C / min, then slowly raise the temperature to 2150°C at a rate of 4.3°C / min, and then keep warm for 0.5h to completely melt the quartz raw material to a molten state;

[0061] S4. Quartz glass molding: In the heat preservation stage, pour the molten quartz prepared in step S3 into the melting and casting molding mold, open the pressing rod device of the melting and casting equipment, and press the glass molten liquid downward for molding; the ambient temperature of the die-casting process is 2150 ℃, the pressure rod force is 150N, the die-casting speed is 1mm / min, and the holding time is 0.5h. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com