Volatile precision stamping oil and preparation method thereof

A precision stamping and volatile technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems affecting the working environment of workers, increasing production costs, affecting production efficiency, etc., to improve environmental protection, increase lubrication effect, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

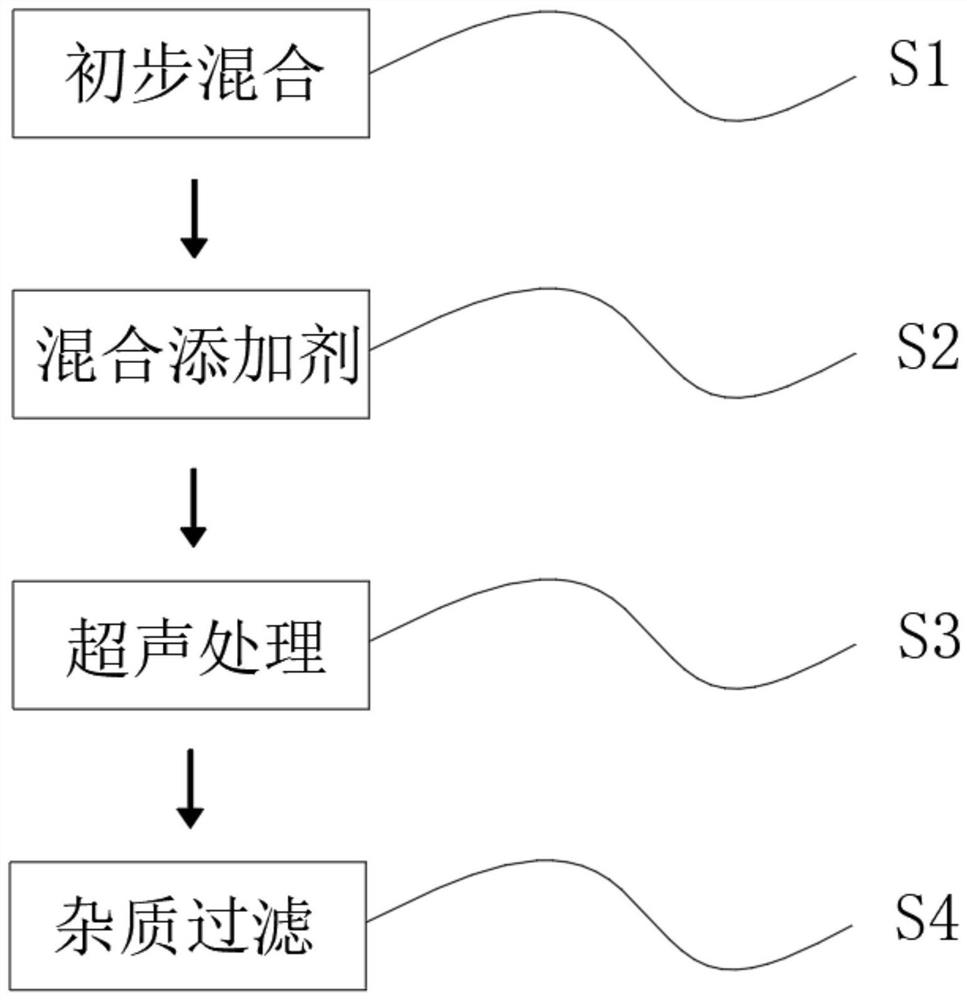

[0023] Example 1, please refer to figure 1 , the present invention provides a technical solution: a kind of volatile precision stamping oil, the preparation material of said a kind of volatile precision stamping oil is made of extreme pressure agent, anti-wear agent, oiliness agent, antirust agent, passivating agent , hydrocarbon solvent oil, surfactant and compound antifoaming agent, and the weight ratio of each material is as follows: 0.1 part of extreme pressure agent, 3 parts of antiwear agent, 5 parts of oily agent, 0.1 part of rust inhibitor, 0.5 part of passivator parts, 60 parts of hydrocarbon solvent oil D60, the balance of D80, 0.3 parts of surfactant, and 0.25 parts of composite antifoaming agent.

[0024] The extreme pressure agent is one or more of sulfurized fatty acid methyl ester, polyvinyl alcohol, talcum powder, sodium silicate, sodium fluoroborate, and zinc stearate. By setting the extreme pressure agent, it plays a role of lubrication , to prevent the meta...

Embodiment 2

[0037] Example 2, please refer to figure 1 , the present invention provides a technical solution: a kind of volatile precision stamping oil, the preparation material of said a kind of volatile precision stamping oil is made of extreme pressure agent, anti-wear agent, oiliness agent, antirust agent, passivating agent , hydrocarbon solvent oil, surfactant and compound antifoaming agent, and the weight ratio of each material is as follows: 3 parts of extreme pressure agent, 0.1 part of antiwear agent, 0.1 part of oily agent, 1 part of rust inhibitor, and 0.05 part of passivator part, the remainder of hydrocarbon solvent oil D70, 0.5 part of surfactant, and 0.1 part of composite antifoaming agent.

[0038] The extreme pressure agent is one or more of sulfurized fatty acid methyl ester, polyvinyl alcohol, talcum powder, sodium silicate, sodium fluoroborate, and zinc stearate. By setting the extreme pressure agent, it plays a role of lubrication , to prevent the metal surface from ...

Embodiment 3

[0051] Embodiment three, please refer to figure 1 , the present invention provides a technical solution: a kind of volatile precision stamping oil, the preparation material of said a kind of volatile precision stamping oil is made of extreme pressure agent, anti-wear agent, oiliness agent, antirust agent, passivating agent , hydrocarbon solvent oil, surfactant and composite antifoaming agent, and the weight ratio of each material is as follows: 1.5 parts of extreme pressure agent, 0.6 part of antiwear agent, 3 parts of oiliness agent, 0.5 part of antirust agent, 0.2 part of passivation agent parts, hydrocarbon solvent oil D60 20 parts D70 60 parts D80 balance, surfactant 0.25 parts, composite antifoaming agent 0.3 parts.

[0052] The extreme pressure agent is one or more of sulfurized fatty acid methyl ester, polyvinyl alcohol, talcum powder, sodium silicate, sodium fluoroborate, and zinc stearate. By setting the extreme pressure agent, it plays a role of lubrication , to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com