Composite positive electrode material and preparation method thereof, positive plate and sodium ion battery

A technology of composite positive electrode material and positive electrode material, which is applied in the field of positive electrode sheet, sodium ion battery, composite positive electrode material and its preparation, can solve the problems of lattice oxygen loss performance, sodium content reduction, capacity reduction and the like, and achieves good stability, The effect of long cycle life and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

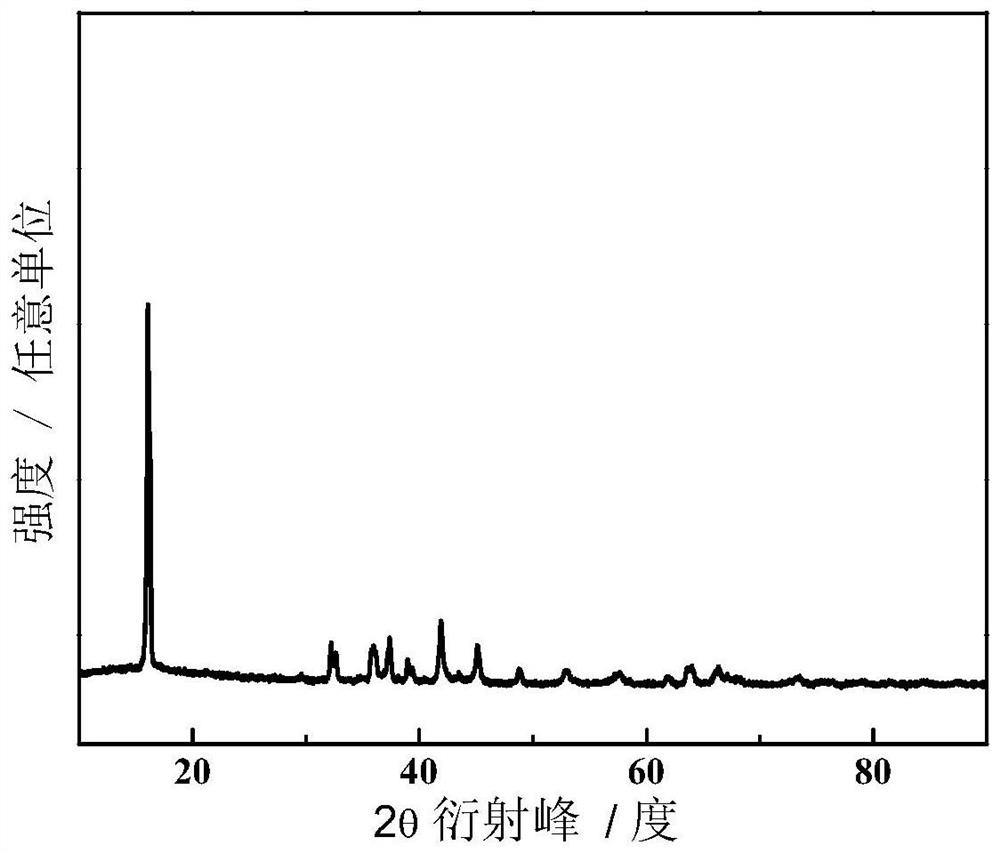

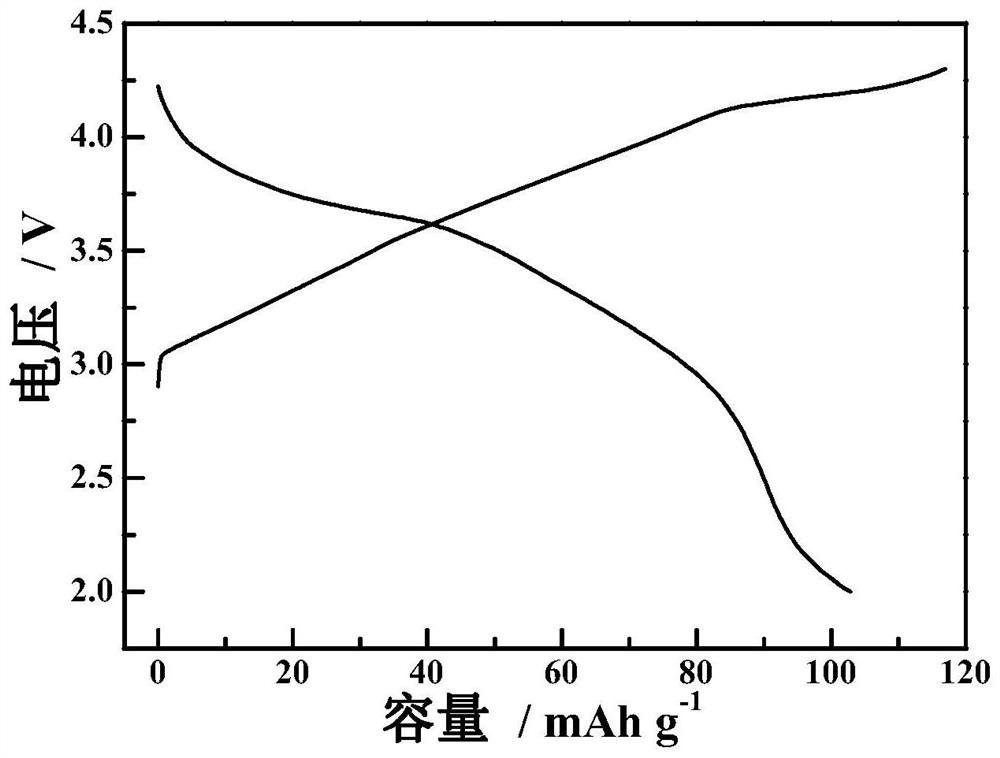

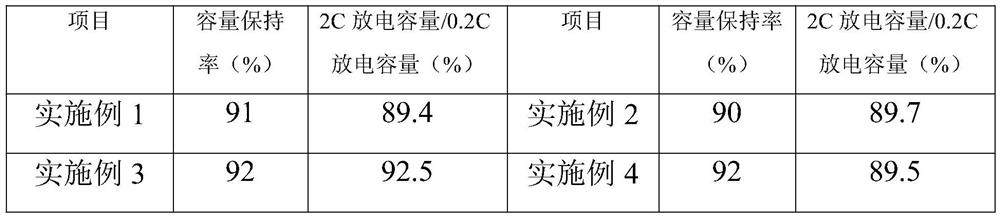

[0039] Step S1, press Na 0.73 Nb 0.003 [Mn 0.63 Fe 0.08 Ni 0.20 Li 0.09 ]O 1.996 f 0.004 stoichiometric ratio, the material was prepared using a direct solid-state reaction method with surface doping. According to the stoichiometric ratio, the Na 2 CO 3 , MnO 2 , Fe 2 o 3 , Ni(OH) 2 , Li 2 CO 3 Mix evenly, and obtain the precursor after ball milling, wherein the ball milling time is 10 hours, the rotation speed is 400rpm, and then the precursor is placed in a muffle furnace, and it is roasted at 900°C for 15 hours in an air atmosphere to obtain a non-surface-doped manganese-based layer shape material.

[0040] Step S2, the above product is mixed with a certain amount of niobium ethoxide in ethanol, stirred and dried at 60°C, and then calcined in air at 600°C for 5 hours to perform Nb doping on the surface. Then the above product was mixed with a certain amount of NH 4 Mix F evenly, and bake at 400° C. in air for 5 hours to perform F doping on the surface. Pro...

Embodiment 2

[0042] Step S1, press Na 0.72 Nb 0.002 [Mn 0.63 Fe 0.08 Ni 0.22 Li 0.07 ]O 1.996 f 0.004 Stoichiometric ratio, the material was prepared by co-precipitation method with solid phase reaction and surface doping. According to the stoichiometric ratio, the NiSO 4 , MnSO4 , FeSO 4 Place in deionized water and mix evenly to obtain a salt solution with a total concentration of 1mol / L, configure 0.5mol / L ammonia solution and 2mol / L NaOH solution as complexing agent and precipitant respectively, and then mix the salt solution, complex The agent and the precipitating agent were injected into the reaction vessel at the same time to carry out the co-precipitation reaction. The temperature of the co-precipitation reaction was 50° C., and the pH value was controlled at 11.0 by adjusting the flow rate of the NaOH solution. The resulting precipitate was centrifuged, dried, and Na 2 CO 3 and Li 2 CO 3 Mix according to the metering ratio, then place in a muffle furnace, and bake at...

Embodiment 3

[0045] Step S1, press Na 0.67 Zr 0.002 [Mn 0.71 Ni 0.19 Li 0.10 ]O 1.998 f 0.002 stoichiometric ratio, the material was prepared using a sol-gel method combined with solid-state reaction and surface doping. According to the stoichiometric ratio, the NaNO 3 , LiNO 3 , Mn(NO 3 ) 2 , Ni(NO 3 ) 2 Mix in deionized water, stir to get a sol, then add citric acid, stir well at 60°C to get a gel, then put it in a muffle furnace, and bake it at 920°C in an air atmosphere for 12 hours to get a non-surface-doped gel. Miscellaneous manganese-based layered materials.

[0046] Step S2: Mix the above-mentioned product with a certain amount of zirconium ethoxide in ethanol, stir and dry at 60°C, and then bake in air at 600°C for 5 hours to perform Zr doping on the surface. Then the above product was mixed with a certain amount of NH 4 Mix F evenly, and bake at 400° C. in air for 5 hours to perform F doping on the surface. The product was analyzed by XRD and had a P2 phase. Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com