Lithium ion battery cathode material and preparation method

A technology for lithium-ion batteries and positive electrode materials, applied in the field of lithium-ion battery positive electrode materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

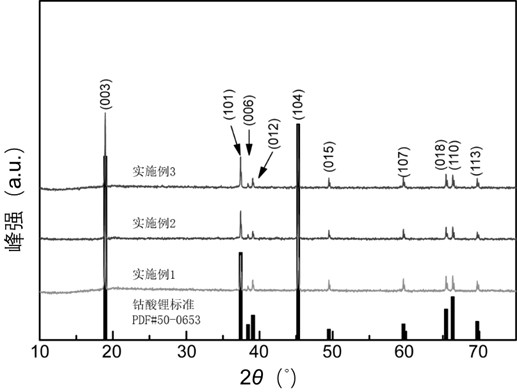

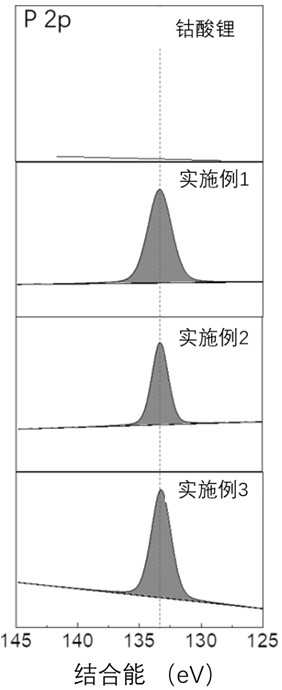

Embodiment 1

[0034]0.03 g of nine nitrate aluminum, 0.0165 g of lithium nitrate and 0.0211 g of sodium hydrogen phosphate were pre-dissolved in 30 ml of water, and then stirred for about 1 hour (the purpose of stirring was mixed), 1 g of lithium cobaltate was mixed, stirred 2 The hour (stirred was mixed), water was mixed at 160 ° C for 5 hours, and then dried in an oven at 80 ° C for 8 hours after centrifugation, then heated at 700 ° C in argon for 5 hours, heating speed 5 ° C min MIN-1After natural cooling, lithium cobaltate material is obtained.

[0035]Among them, aluminum salt (aluminum nitrate nitrate nitrate) and lithium molar ratio of cobaltate: 0.00783: 1, lithium salt (lithium nitrate) and lithium molar ratio of cobaltate: 0.0234: 1, phosphate and cobalt acid lithium molar ratio: 0.0156 : 1.

Embodiment 2

[0037]0.0417 g of nine nine nitrate aluminum, 0.0116 g of lithium nitrate and 0.0220 g of sodium hydrogen phosphate were pre-dissolved in 30 ml of water, stirred for about 1 hour, mixing 1 g of lithium cobaltate was mixed, stirred for 2 hours, water at 160 ° C After 5 hours, it was dried in an oven at 80 ° C for 8 hours after centrifugation, and then heated at 700 ° C in argon for 5 hours, and the temperature increased speed of 5 ° C min.-1After natural cooling, lithium cobaltate material is obtained.

[0038]Among them, aluminum salt (aluminum nitrate nitrate nitrate) and lithium molar ratio of cobaltate: 0.0109: 1, lithium salt (lithium nitrate) and lithium molar ratio of cobalt acid: 0.0165: 1, phosphate ammonium hydrogen phosphate and cobalt molar ratio: 0.0163 : 1.

Embodiment 3

[0040]0.0467 g of nine nine nitrate aluminum, 0.0086 g of nitrate and 0.0219 g of sodium hydrogen phosphate were pre-dissolved in 30 ml of water, and then 1 g of lithium cobaltate was mixed, stirred for 2 hours, water at 160 ° C for water After 5 hours, it was dried in an oven at 80 ° C for 8 hours after centrifugation, and then heated at 700 ° C in argon for 5 hours, and the temperature increased speed of 5 ° C min.-1After natural cooling, lithium cobaltate material is obtained.

[0041]Among them, aluminum salts (aluminum nitrate nitrate nitrate) and lithium molar ratios: 0.0122: 1, lithium salt (lithium nitrate) and lithium molar ratios: 0.0122: 1, phosphate and cobalt-cobalt molar ratio: 0.0162 :1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com