Sodium-ion battery positive electrode material additive and sodium-ion battery positive electrode material

A technology of sodium ion battery and positive electrode material, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problem of reducing the specific capacity and cycle stability of sodium ion batteries, unable to take into account the cycle performance and battery capacity, and the use of sodium ion batteries. Shorter life and other problems, to achieve the effect of facilitating rapid transfer, reducing lattice collapse, improving specific capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The present embodiment prepares additive according to the following steps:

[0060] 1) mixing and reacting sodium salt, nickel salt, M salt and solvent to form a mixed slurry;

[0061] 2) Dispersing NaA in a solvent to obtain a NaA solution;

[0062] 3) Add the NaA solution into the mixed slurry, disperse for 30min-2h, filter it with suction and dry it in an oven at 120°C;

[0063] 4) Put the dried powder in a rotary kiln for calcining to obtain the additive.

[0064] Preferably, the calcination is carried out under a protective gas, and the calcination includes:

[0065] One-stage calcination: the calcination temperature is 100-300°C, and the calcination time is 2-5h;

[0066] Two-stage calcination: the calcination temperature is 800-1000°C, and the calcination time is not less than 6 hours.

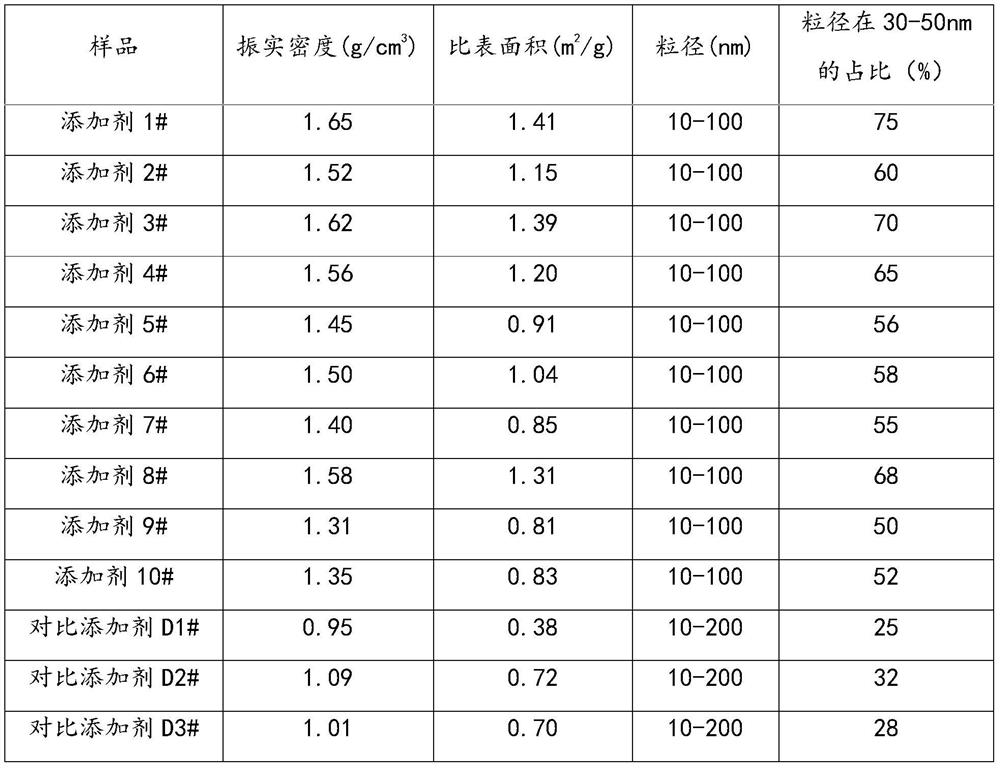

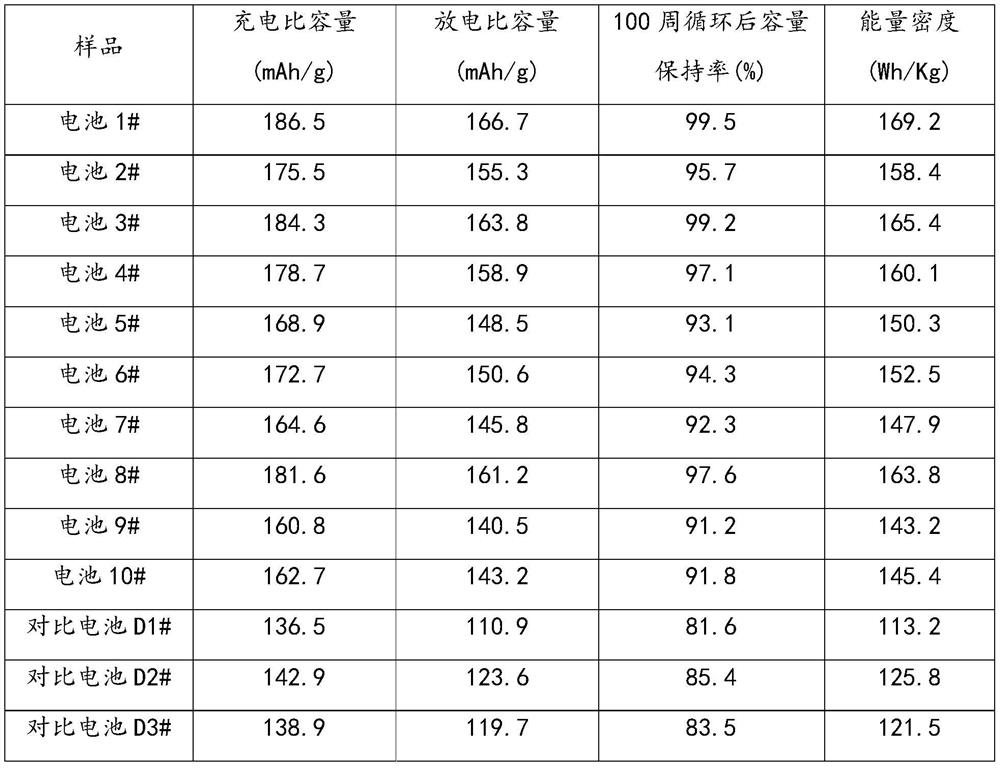

[0067] Prepare additives 1#-10# and comparative additives D1#-D3# according to the above steps, as follows:

[0068] Additive 1#

[0069] (1) 77.9g CH 3 COONa, 82.1g (CH ...

Embodiment 2

[0111] Preparation of positive electrode matrix material:

[0112] 55.0gCH 3 COONa, 82.1g (CH 3 COO) 2 Ni·4H 2 O and 164.2g (CH 3 COO) 2 Mn 4H 2 O (the mol ratio of Na salt, Ni salt, Mn salt is 0.67:0.33:0.67) joins in 1L ethanol respectively, obtains sodium acetate solution, nickel acetate solution and manganese acetate solution; Then sodium acetate solution, nickel acetate solution and The manganese acetate solution is mixed and placed in the autoclave, and the autoclave is sealed;

[0113] Control the pressure of the autoclave to 15MPa, and react the autoclave in an oil bath at 160°C for 10 hours;

[0114] The product was washed with water and ethanol three times respectively, and dried in a spray dryer at a temperature of 80°C for 10 minutes. After the product was washed with water and alcohol, the residual alkali of the product was effectively reduced, and the stability of the material in the air was improved. sex;

[0115] Put the sagger containing the cleaned p...

Embodiment 3

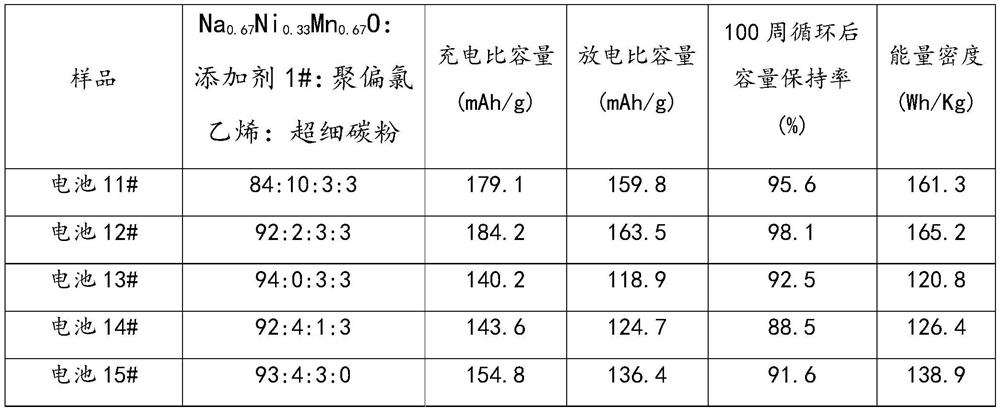

[0121] The positive electrode base material Na prepared in embodiment 2 0.67 Ni 0.33 mn 0.67 o 2 , the additive 1# that embodiment 1 prepares, polyvinylidene chloride and superfine carbon powder prepare the positive pole of sodium-ion battery according to the weight ratio of following table 3 respectively, take hard carbon as negative pole, take sodium hexafluorophosphate as electrolytic solution, respectively Assemble soft-pack batteries 11#-15#, and conduct performance tests on them. The results are shown in Table 3 below.

[0122] table 3

[0123]

[0124] According to the batteries 11#-15# prepared in this embodiment, it can be seen that Na 0.67 Ni 0.33 mn 0.67 o 2 , The ratio of additives, polyvinylidene chloride and ultrafine carbon powder can affect the charge-discharge specific capacity of the battery and the cycle performance of the battery. With the combination of additives and positive electrode matrix materials, a positive electrode material with double-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com